The German economy is characterised by medium-sized companies which, thanks to a strong corporate culture, a clear strategy and innovative strength, manage to be leaders in their field and hold their own against international competition. They form the backbone of our economy. The Felix Schoeller Group is one of these so-called hidden champions.

In its more than 125-year history, the family business has succeeded in constantly recognising new market and customer requirements and reinventing itself. As a speciality paper producer, the Felix Schoeller Group is now a sought-after partner when it comes to sustainable packaging solutions and substitute materials for aluminium and plastic.

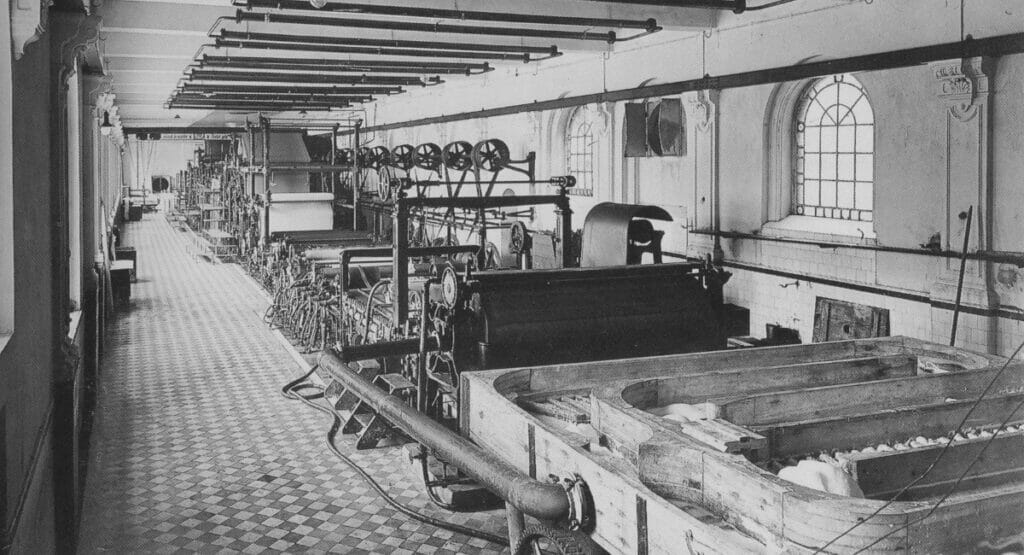

The early years: vision and pioneering spirit

Company founder Felix Herrmann Maria Schoeller was a man of vision. So was the Like many of his contemporaries, the son of a papermaker was fascinated by the emergence of photography at the end of the 19th century. He recognised the rapidly growing demand for silver salt photographic paper at an early stage and developed a business idea based on this insight. In 1895, he took over a paper mill east of Osnabrück and founded the Felix Schoeller paper mill. Even then, the company focussed on diversifying its product range and, in addition to photographic base papers, also produced document papers, drawing and packaging papers. This laid the foundation for the triumphant success of the family business. The start of an eventful company history, characterised by change and adaptation.

At the beginning of the 20th century, the photographic paper business flourished and Felix Schoeller was one of the main innovators in this market segment. When the founder died in 1907, his sons Felix Heribert, Lothar and Gerhardt Schoeller took over the management of the still young company. It is not unusual for a change of management and generation to mark a turning point in the success story of a company. Not so under the new management, who vision of the company founder and recognised the enormous market potential for photographic papers. The expansion followed accordinglyinitially within Europe. And in the year In 1912, the company ventured across the pond and founded the Felix Schoeller Paper Company in the USA. The subsidiary set up in New York and in 1932 - in the spirit of the innovative company founder - made its first attempt to produce coated paper.

Evolution instead of revolution: the success story continues

After the Second World War, there was another generational change. In 1949, the third generation, Klaus, Felix Richard and Gert Schoeller, joined the company management. The company's international success continued under the new management. Thus it had In 1962, exports accounted for over 60 per cent for the first time. The joy of innovation, which has been part of the company's DNA since its foundation, was also decisive for its success on the global market during this phase. One example: Already In 1964, the company built the first extruder for coating photographic base papers and thus provided the basis for the decision in 1980 to focus the product range on photo base papers. This was followed in 1986 by the PM 1, the world's most powerful paper machine for photo base paper at the time.

Product diversification and growth: open to new ideas

The advent of digital photography triggered a rethink. The company management recognised the potential consequences of digital photography at an early stage and responded with a new corporate strategy. The company broadened its product range again and expanded into the production of high-quality speciality papers for inkjet printing systems and decor papers. in. In 1993, the decor business of Technocell AG was taken over and Technocell Dekor was founded.

The new strategy quickly bore fruit. A major step in the course of growth was the expansion of the Weißenborn mill in 1998 with an investment volume of 300 million euros. This made the plant the world's only integrated site for photo imaging papers. In the 2000s, the Expansion with locations in Canada, Russia, Japan, Malaysia and Australia further. In 2001, Felix Schoeller acquired a majority stake in the Kunz Group's decor paper mill in Drummondville, Canada. In addition, the portfolio was constantly expanded, as in 2004 with the introduction of the pre-impregnated PRIP®. Today, the Felix Schoeller Group has eleven production sites and representative offices worldwide.

The current company management: on course for a sustainable future

Hans-Christoph Gallenkamp has been managing the family business in the fifth generation since 2018. The qualified paper engineer began his career in the family business back in 1997. He worked in a wide variety of positions before taking over as CEO. Under his leadership, numerous initiatives to position the Felix Schoeller Group for success. With Felix Schoeller Packaging, this includes another business segment: sustainable packaging solutions.

Today, Felix Schoeller is one of the leading paper manufacturers, producing both base paper and coated paper, combining Extensive paper and coating expertise with state-of-the-art machines and technologies. Expertise such as the printability of paper has been transferred to the packaging segment. In the spirit of sustainability, the experts are helping their customers to gradually replace conventional materials - such as plastic or aluminium - with more environmentally friendly solutionswithout losing sight of the functionality and product protection of the packaging. The product portfolio includes the sustainable PrimePaper paper base and the FlexPaper composite paper range.

FlexPaper pure: the sustainability star

One product stands out from the extensive portfolio: FlexPaper pure. It is an expression of Felix Schoeller's innovative strength and, with a high paper content of 95 per cent, makes an important contribution to an effective circular economy and brings sustainability to the entire life cycle of the packaging. FlexPaper pure is produced in a thin-layer extrusion process. It is based on renewable, FSC-certified pulp from sustainable forestry. In addition to ecological aspects, the speciality paper impresses with very good printing results in flexo and gravure printing to position the respective product attractively in the retail trade. FlexPaper pure is suitable for disposal in waste paper.

However, sustainability does not only play an important role in product development. For the management team and Hans-Christoph Gallenkamp, the combination of ecological action and economic principles for sustainable business is an integral part of the Felix Schoeller Group's philosophy. The company is certified for quality, safety and the ecological use of resources as well as for climate-neutral paper production. The company has recently received the EcoVadis Gold global sustainability rating three times in a row. With a rating that rose again in 2022 to 68 the Group ranks among the top five per cent of all companies assessed.

125 years and not a bit tired

The history of the Felix Schoeller Group is an example of how family-run companies with vision, market understanding and customer focus can hold their own on the global market. High-quality Speciality papers developed, manufactured and marketed for a wide range of applications and market segments in numerous industries and markets worldwide. The diverse product portfolio also includes flexible paper composites for packaging, photo and digital printing papers. In 2021, the global market leader for photographic and decor papers produced around 545,000 tonnes of speciality papers for around 1,800 customers in more than 65 countries with over 3,700 employees worldwide. Turnover rose to over 1 billion euros (1,048.6 million) for the first time in the company's more than 125-year history.

The 125th anniversary was celebrated in 2020. The secrets of the family business's success? It grew steadily, but always sustainably. Long-term success was more important to all generations than short-term profit. The Second major success factor: being open to new ideas. The constant willingness to recognise trends and to draw the consequences for your own company. And to see this not as a threat, but as an opportunity. Accordingly, the course is set for future success.

The 2030 vision is: "We are a family business. Today and for the next generations."

More news from the magazine

Translucent paper seal labels for pharmaceutical packaging

Packaging machine manufacturer in flow

Powerful automation for mills

Decentralised signal processing with the Schmersal Safety Fieldbox