Invented in 1953 by Swiss engineer Roger Perrinjaquet, the magic wand is still a household name in domestic and professional kitchens alike. The world's smallest food processor is still produced 100 per cent in Switzerland. Esge AG uses systems from the labelling provider Bluhm Systeme for large-format printing on its cardboard packaging.

„We manufacture all the parts for our products in Switzerland, wind the motors ourselves and fulfil the highest quality standards,“ explains Erich Eigenmann, CEO of Esge AG. The kitchen appliances are exported from Mettlen in Switzerland to over 40 countries. „To simplify handling and stock management, our customers and distributors want us to label our outer cartons with EAN codes“, adds COO Marcel Buff. This is done by several printing systems from the labelling provider Bluhm Systeme.

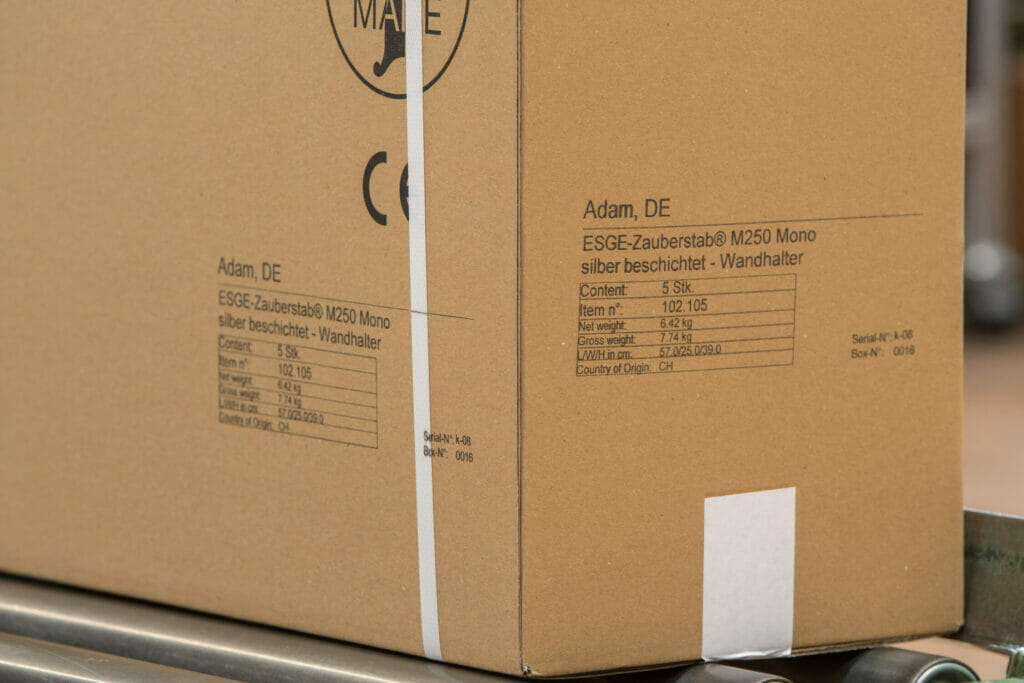

After production, the Esge employees pack the wands in outer boxes. So that the company only needs to stock one variant of outer cartons, the neutral cartons are individually printed with content-specific information. Depending on the customer's requirements, these may include the article name, article number and weight in plain text or encoded as an EAN code.

This wealth of information requires a relatively large print area. For this purpose, the company uses a piezo inkjet system developed by Bluhm Systeme's Markoprint division together with ink manufacturer Seiko. This so-called Markoprint integra PP 108 enables large character printing with character heights of up to 108 millimetres and therefore offers a real alternative to more cost-intensive labelling.

Two-sided labelling

To ensure that the contents of the cardboard boxes can be read from several sides depending on how they are stacked or stored, Esge AG prints identical information on two sides of the outer boxes. For this purpose, the print heads of two systems were mounted on the side of a conveyor belt. This allows them to automatically print on the cartons as they move past them. After the cartons have passed the first printer, they reach the part of the conveyor belt that has been mounted at a 90-degree angle. They pass the second printer, are printed on the second side and reach the outgoing goods area.

„We print 1,500 cartons per conveyor belt every day: That corresponds to 300,000 transport packages per year,“ explains Marcel Buff. This is no problem for the integra PP 108 printers. They deliver information at up to 150 metres per minute at a resolution of 360 dpi The text is applied to absorbent surfaces at an above-average speed. Lightning-fast text changes with more than 50 variable data per second are possible.

Automatic transmission of print data

„It was very important to us that the print data could be transferred to the systems easily and very quickly,“ recalls Marcel Buff. The devices are operated directly by the production staff. You select the respective print job conveniently on the PC and thus control the printers.

The integra PP-108 systems are also particularly easy to maintain during operation. The recirculating ink system, for example, ensures that no nozzles fail and that the print image remains razor-sharp at all times. As the ink can be refilled during operation, there are no interruptions to production.

In addition to cardboard boxes the piezo printers can also print on non-absorbent surfaces if required reliable and abrasion-resistant. They use a UV ink that dries out under UV light within milliseconds.

Unique is the bicolour version of the PP 108, which uses two ink colours simultaneously. This enables, for example, labelling in black and red with just one device. Other available colours are green and blue.