Companies are currently facing many challenges. Automation with the help of robotics or sensor, vision and AI technology can be a solution here. If you are wondering whether the purchase of a collaborative or mobile robot is worthwhile for your own business, Omron's new return on investment (ROI) calculator can help.

Business leaders in Germany and around the world are currently facing one challenge after another: In addition to the exploding costs caused by the energy crisis, there are supply chain problems, a shortage of skilled workers, sustainability requirements and advancing digitalisation, all of which demand coherent approaches. Small and medium-sized enterprises (SMEs) in particular must quickly find ways and means to overcome these hurdles. Automation provides a remedy - this includes robotics such as cobots and AMR (autonomous mobile robots) as well as sensor, vision and AI technology. Although companies are well aware of the advantages of such technologies, studies also show that many are still sceptical about their actual use.

According to German Robotics Mirror around 48.3 per cent of respondents without application experience fear that the use of robots would be associated with high costs. One IDC study has also discovered that more than two thirds (70 per cent) of the companies surveyed are planning to use intelligent automation. If you are currently wondering whether it is worth purchasing a collaborative or mobile robot for your own business, the new return on investment (ROI) calculator from Omron. It provides a quick overview of the return on investment and shows when a robotics investment will cover its costs.

In Germany, for example, 82 per cent of the country's value added comes from SMEs. In the EU as a whole, the figure is around 56 per cent. Extremely important is also the importance of SMEs as employers, but in many places it is becoming increasingly difficult to find employees. Companies are therefore urgently required to find new ways to find and retain suitable employees.

Technologies that take over manual and repetitive tasks can increase employee safety and efficiency. Cobots are ideal for SMEs due to their flexibility and many different possible applications. The fact that this segment has enormous potential is shown by studies such as that by MarketsandMarkets: According to the report, the market for collaborative robots is expected to grow from USD 1.2 billion in 2021 to USD 10.5 billion in 2027. An annual growth rate (CAGR) of 43.4 per cent is forecast until 2027.

But anyone dealing with this topic for the first time is faced with a mountain of questions and considerations. Omron has summarised four key aspects that should be considered at the start of automation projects, to drive projects forward, reduce scepticism and get stakeholders on board.

Focus on application scenarios and scale slowly

The first question that companies thinking about automation and cobots should focus on is not: should they invest in robotics? Instead: Which processes can be made more efficient and how? Some tasks that are very intricate and customised can be automated, but they involve immense effort - both in terms of time and resources. When getting started with automation, it is advisable to start with small projects and then scale up gradually, adding new workflows, expanding the fleet, etc.

Using robots to support employees

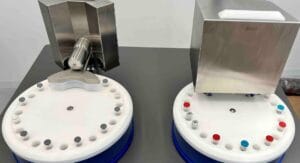

Robots score points for flexibility. They can be adjusted and customised, used in fleets and more. Depending on the product and area of application, various positions and extensions are conceivable so that they can be adapted to new or changed tasks. However, this does not mean that they replace employees. Instead, it is about a well-orchestrated interaction between man and machine. Medium-sized companies in particular should initially focus on individual tasks and not think and plan too complexly. An extension of the cobot, for example with a camera and image processing system (Vision Technology), is also possible at a later date, This is only possible if a robotics partner is chosen who can cover various areas from a single source and offer a good partner network. The focus is on: How can robotics help employees? Which manual tasks can be handed over to a robot so that the human employee can concentrate on more value-adding tasks? The Loading and unloading machines as well as palletising and depalletising are processes that can be automated relatively quickly and easily.

Getting employees on board and specialising

Ideally, robots perform tasks that are constantly repeated and very precise, but they only do what the programme, or the employee, tells them to do. The human remains the specialist, the robot takes over repetitive and monotonous tasks. Robotics is not a panacea or a replacement for human employees. This thinking should permeate every automation project - also to allay employees' fears. Specialists are still needed for assembly, process optimisation and maintenance, for example. In addition, employees should be aware of the possibilities and be trained to make optimum use of new technologies. While robots take over palletising, sorting, material feeding or quality control, for example, employees can be more creative and add more value.

Relying on experience and partner networks

In order to expand the tasks and possibilities of robots, third-party devices are required, such as an image processing and inspection system. If SMEs in particular can rely on a robotics partner at their side who offers support from a single source, this relieves them of a lot of work and worry: A lack of expertise within the company's own ranks is covered by experienced partners. In an Omron survey, almost 90 per cent of IT managers stated that they are dependent on external consultants when it comes to Industry 4.0 and data analysis. SMEs therefore not only need smart technology, but also holistic providers and experienced system integrators.

Nine out of ten companies want to introduce robot automation in their respective infrastructures by 2030. Mobile robots and cobots are easy to use and transport in this context. This makes them a good option for companies that want to make their production processes more flexible and efficient. Omron wants to support SMEs with automation and offers leasing options, for example, to keep initial investment costs low.

The ROI calculator also helps to easily evaluate investments in cobots and mobile robots. How companies of all sizes can benefit from the potential for automation and don't have to worry about opaque or unpredictable costs.

SourceOmron : Omron

Omron - More news

Robotic solutions for flexible and intelligent production

EU packaging regulation: opportunity for recycling and traceability

Barcode reader from Omron combines imaging with smart decoding

Strategically mastering the challenges of modern production