Labelling is indispensable in modern production and logistics in order to control the internal and external flow of materials. At the LogiMAT 2023 provides REA, Specialist for industrial labelling and code verification, its labelling systems for the intelligent automation and control of goods flows before.

Powerful technologies automate and control internal and external flows of goods in modern production - from procurement to production to delivery. Customised, reliable and Reliable labelling is their basis and also indispensable for complete traceability. To achieve this, direct printing and labelling systems must be integrated into the infrastructure and production environment and support the processes with precise and reliable operation.

The labelling solutions from the South Hessian full-range supplier meet all of these requirements REA Electronics, Whether printing systems from the REA Jet product line or labelling solutions from REA Label. The systems in the REA Verifier product line check and verify the quality of applied codes.

Inexpensive, versatile colour label printing

As a compact colour label printer, the new REA Label Color JET-2 is a cost-effective alternative to external printers and comes in three versions. Its core is the standard model: It prints small and medium quantities of full-colour labels individually or in series with a print width of up to 21 centimetres and the highest resolution of up to 1,200 dpi. Users can choose between DYE ink, pigmented or nanopigmented ink for the substrate, from matt paper to high-gloss polyethylene - depending on the type of ink selected.

A printer setup is not required because the labels are automatically fed in, their dimensions read out and displayed. Depending on the printer model, the result is removed manually using the tear-off edge, cut off automatically with a circular blade and then placed by hand or applied to the product directly from the integrated label dispenser after cutting.

With its compact design and robust, powder-coated housing, the REA Label Color JET-2 is the right choice for industrial use in production, logistics, automation and everywhere else, where high-quality colour labels must be available „on demand“. In addition, the majority of its individually replaceable components are made of recyclable material.

Labels on up to three pages

The REA Label pallet labelling system offers great flexibility in labelling. It applies labels to one, two or three sides of the pallet in throughput or at a standstill. The REA Label high-speed servo labeller is the perfect partner for end-of-line applications with differently sized packaging: It places shipping labels quickly and precisely in the right place on boxes or parcels of different heights, as it automatically recognises varying container heights. With its print quality and top performance at printing and dispensing speeds of up to 2,500 products per hour, it significantly increases the level of automation in production.

Efficient labelling of secondary packaging

The REA Jet GK 2.0 high-resolution coding system prints captive and freely combinable texts, logos and graphics with variable data at heights of up to 100 mm with just one print head and with pin-sharp edges. Its solvent-free inks are suitable for especially for labelling secondary packaging with porous and absorbent surfaces such as cardboard, paper or wood.

A robot cell will show visitors to the trade fair the perfect interaction of products from the REA Jet and REA Label lines with the REA Verifier VeriMax Inline, the Inspection device for 1D barcodes and 2D matrix codes to increase the first read rates of printed codes.

At the second REA stand, a wide range of Solutions for quality control of 1D and 2D matrix codes shown. The devices in the REA Verifier product line check codes under different conditions, on smooth surfaces or in diffuse light, as a mobile inspection solution or permanently installed in machines and systems for inline inspection.

Verification of label content and code quality

The REA LabelTower shows that mislabelling is a thing of the past. The quality of 1D/2D codes and also the label contents The LabelTower uses an innovative combination of technologies to check the quality of the label in a single step: It checks the legibility, contrast, printing precision and standard-compliant quality of the printed codes and also compares the layout, font and graphic elements of the label with the target specification. The intelligent system is particularly helpful in companies that want to optimise their Labelling products for export in different languages, and at the same time want to ensure a high first read rate of the codes.

Source: REA Electronics

REA at the LogiMAT 2023: Hall 4, Stand D08 and Hall 1, Stand K13

REA - More news

REA presents future-proof labelling solutions

Management change at REA Elektronik

Labelling and code verification for logistics

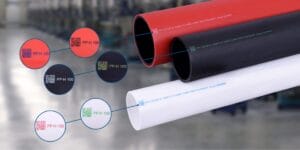

Plastics colour-coded