At this year's interpack, Syntegon will be focussing on the hot topics of resource conservation and digital technologies. The company is presenting a flexible complete solution for coffee with an integrated Industry 4.0 solution.

With the packaging system for the primary and final packaging of coffee beans Syntegon at this year's interpack from 4 to 10 May in Düsseldorf, two hot topics at the trade fair: Resource conservation and digital technologies. Because with the End-to-end packaging line consisting of PMX, Product Handling System and Elematic 3001 WAH the company shows beside modern control technology also offers a new flexible and multifunctional solution for product handling. The line packs coffee beans in stand-up pouches - the product handling system brings together products from two infeed lines, monitors the quality and transports them to a case packer for final packaging. An integrated I4.0 solution also monitors machine statuses and thus contributes to the efficiency and cost-effectiveness of the line.

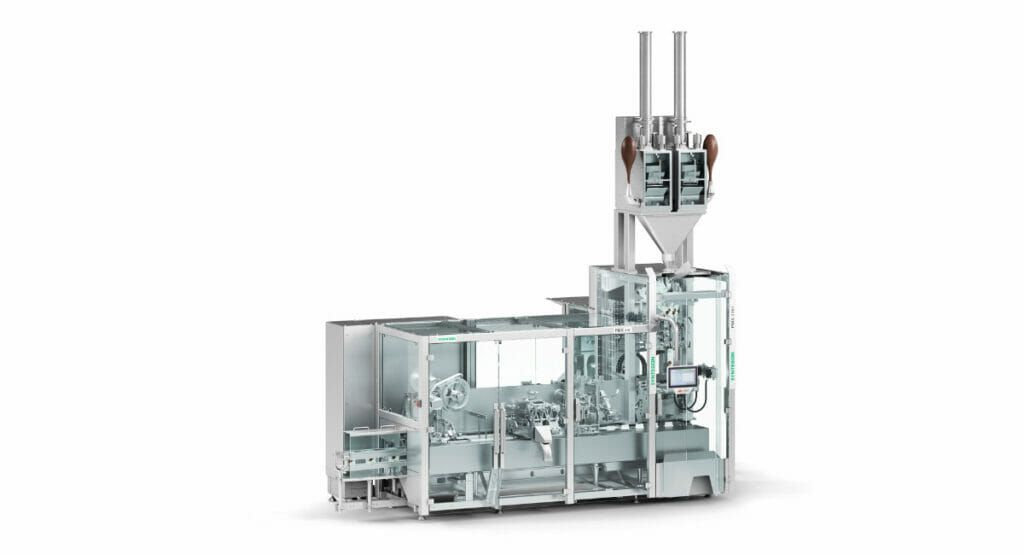

The system starts with the flexible PMX packaging machine for ground coffee and whole beans. Thanks to Quick format change and four-edge sealing Versatile use for different packaging formats. Its modular concept enables manufacturers to realise specific customer requirements with efficient output and to react quickly to changing market demands - as a single-tube version at interpack, the PMX packs 340g of coffee beans at a speed of 65 bags per minute.

Opportunities through Industry 4.0

At the same time, the machine fulfils the highest requirements for sustainability and digitalisation: it processes Recyclable packaging materials and flavour protection valves made from mono-materials. The packaging line is also equipped with Synexio Empower, a smart machine I4.0 solution that monitors energy and resource consumption through condition monitoring, data acquisition and visualisation in real time - and thus realises the intelligent self-optimisation of the PMX. Thanks to detailed OEE analyses and predictive maintenance, manufacturers can also improve their plant efficiency and reduce costs. An on-premise system architecture ensures the necessary data security - if required, the solution also supports the secure data supply of Syntegon's Synexio Cloud.

At the trade fair stand, visitors can experience live the possibilities that the I4.0 solution offers to better support operating personnel: These include, for example detailed instructions through the use of augmented reality, autonomous condition monitoring or the simplified connection of secondary machines.

Comprehensive product handling system

Once the coffee beans have been packed, the new product handling system takes the bags from two infeed lines, brings them together and transports them to the downstream Elematic 3001 WAH case packer. The freely movable and individually programmable mover glide through the process without touching other machine parts thanks to a newly developed electromagnetic levitation technology - this minimises component wear.

The product handling system fulfils several functions during the feeding process in a compact design: it mixes, rotates, weighs and places products according to the configuration and controls them in the process. The combination of Flexibility and multifunctionality not only make the product handling system an all-round talent - fewer machines and components are required in the packaging process.

„The multifunctional technology is a decisive advantage of the product handling system. The latest control technology enables the handling process to be adapted without time-consuming format changes, and operators can configure different formats at the touch of a button.“

Bernhard Vaihinger, Product Manager for case packers at Syntegon

Sustainability with a case packer

An Elematic 3001 WAH Wraparound case packer in two formats then packs ten or eight coffee stand-up pouches into one pack. In addition to its high flexibility for numerous product formats, the case packer makes an important contribution to sustainability: it processes Corrugated cardboard made from recycled and alternative packaging materials, such as grass, coconut or cup plant-based (Silphie). The machine is also particularly resource-efficient, as Bernhard Vaihinger explains: „The Elematic 3001 WAH only applies adhesive selectively. Compared to conventional adhesive application methods, we save up to 40 per cent adhesive material..“ An integrated checkweigher ensures reliable quality control and therefore fewer complaints - thanks to the full integration of the checkweigher and the gluing unit, the machine layout remains compact.

The case packer also scores points with an assisted format changeover: operators can easily choose between different configurations via an HMI. This includes a Combination of automated processes, the proven tool-free Elematic Click system, RFID technology and electronic shelf label displays This saves time and is less prone to errors.

Source: Syntegon

Syntegon at interpack: Hall 6, Stand A31-B31

More news about packaging machines

Three applications, one solution

Packaging machine manufacturer in flow

Sacmi acquires majority stake in Groupe Emballage Technologies

Ulma shows smart solutions for fresh products