Drive specialist Nord Drivesystems is bringing its modular product kit to interpack. It includes decentralised frequency inverters and surface finishing for wash-down or spraying applications.

Nord Drivesystems realises drive solutions for all stages of the packaging process that meet the respective application-specific requirements and at the same time can contribute to a reduction in the total cost of ownership (TCO). On the interpack the company presents its modular product system and its extensive expertise in packaging automation. The exhibition highlights include the decentralised frequency inverter NORDAC ON/ON+, the IE5+ synchronous motor, the patented DuoDrive geared motor and the nsd tupH surface finish.

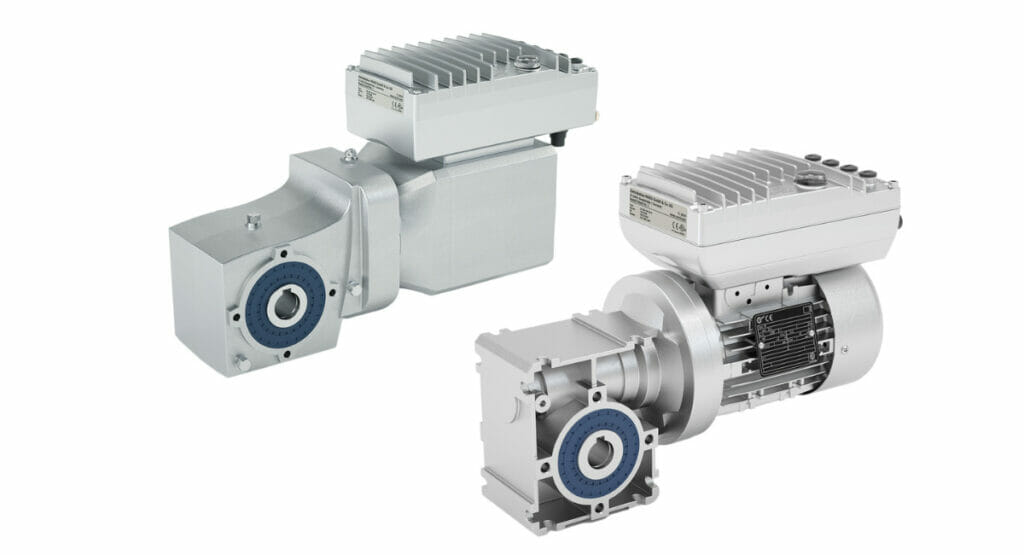

The decentralised frequency inverter NORDAC ON/ON+ is characterised by an integrated Ethernet interface (ProfiNET, EtherNET IP and EtherCAT can be switched via parameters), complete pluggability and an extremely compact design. The smart inverters can be integrated into packaging systems and save space and the complex wiring with motor cables, that require centralised frequency inverters. Two variants are available: While the NORDAC ON designed for operation with asynchronous motors, the NORDAC ON+ for combination with the highly efficient IE5+ synchronous motors.

Nord is setting new standards in terms of energy efficiency with the IE5+ synchronous motor. Thanks to permanent magnet synchronous motor technology (PMSM), it realises a Efficiency of up to 95 per cent - and relatively constant over a wide speed and torque range. This means that the IE5+ motor also offers optimum energy consumption performance in partial load and partial speed ranges and even tops the highest defined energy efficiency class IE5.

The patented DuoDrive is a revolutionary integrated geared motor concept and covers a power range of up to 3 kW. It combines the IE5+ motor with a single-stage spur gearbox in a single housing. The Constant motor torque over a wide speed range enables a consistent reduction in variants and operating costs. Together with the simple plug-and-play commissioning, this results in a significant reduction in the total cost of ownership (TCO) compared to previous drive systems. The wash-down design with smooth surfaces and non-ventilated construction fulfils high hygiene requirements and ensures optimum cleanability.

Both for the NORDAC ON/ON+ as well as the IE5+ synchronous motor and the DuoDrive geared motor, the nsd tupH surface finish is available. In a special process, the surface becomes corrosion-resistant and harder, making aluminium as corrosion-resistant as stainless steel. This is not a coating, but rather the Surface finishing creates a protective layer that is permanently bonded to the base material. This means that nothing can flake or peel off. The drives are easy to clean and are largely resistant to acids and alkalis.

Source: Nord Drivesystems

Nord Drivesystems at interpack: Hall 6, Stand C26

More news about packaging machines

White paper | How to make packaging machines more dynamic through lightweight construction

Three applications, one solution

Packaging machine manufacturer in flow

Sacmi acquires majority stake in Groupe Emballage Technologies