Sensors installed in the bottling plant are often inconspicuous, yet indispensable for efficient processes. At the traditional Dinkelacker brewery, sensor technology from Leuze is used at almost every station. The demands placed on the technical components are very high, as they also have to withstand strong vibrations and frequent cleaning processes.

The Dinkelacker family brewery in Tübinger Straße in the centre of Stuttgart was founded back in 1888. The high The quality standards of its products are also reflected in the technical components used in production. again. That is why the company relies on the application expertise of Leuze and on sensor technology that fulfils the highest requirements for reliability, robustness and hygiene.

Sensor technology during filling

„To ensure that operations run smoothly, we rely on particularly robust and reliable sensors. Only selected sensor solutions can do this,“ explains Florian Fahr, Head of Technology at Dinkelacker. This is why the brewery relies on Sensor People technology from Leuze.

„Reflection light barriers from our PRK series (reflection light barrier with polarisation filter) were primarily installed here. This series is particularly suitable for applications in the beverage industry. The metal housing of the optical sensors is insensitive. The devices can therefore also work optimally in harsh environments.“

Andreas Eberle, Local Industry Manager Packaging at Leuze

It is important that the optical switching devices recognise even highly transparent objects such as bottles and shiny plastic crates with different imprints thanks to the reflection principle. At Dinkelacker, the technology from Leuze has proven its reliability in practice, as Andreas Eberle knows: „Many of the sensors have been doing their job precisely in the family brewery for decades. Some of them were installed at Dinkelacker in the late 1990s and early 2000s.“ By focussing on one sensor series, the brewery fewer different spare parts in stock and can react quickly in the event of a rare defect. Should a problem nevertheless occur, the proximity to the Sensor People headquarters with immediate support is appreciated.

Material flow without obstacles

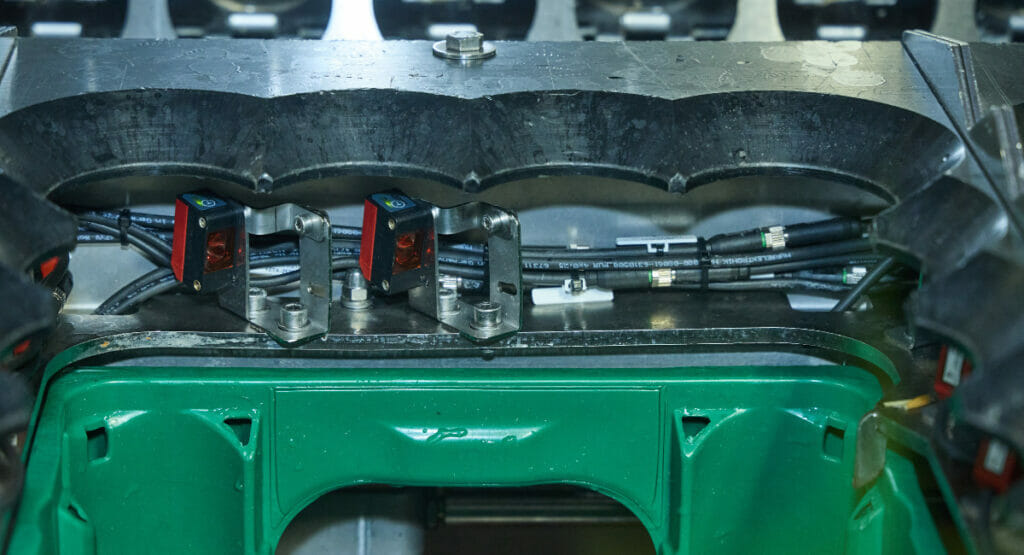

The Leuze sensors are used at various points in the bottling process and each has specific tasks. The process begins before bottling with the cleaning of bottles, beer crates and kegs. Cleanliness and hygiene play a major role. The PRKOptical sensors are installed on the individual belt sections and recognise pallets, barrels, beer crates or even bottles. This automatically regulates the speed of the belts and prevents traffic jams and collisions.

Dinkelacker has installed around 100 sensors on the conveyor belts in the barrel filling area. Up to 240 barrels per hour are cleaned and filled there. Two new Robots support the employees here: they lift the empty or full barrels and place them on the conveyor belt or the pallets. Dinkelacker installed the robots at the time of the restaurant closures during the coronavirus pandemic. Safety technology from Leuze also comes into play for the robots: MLD multiple light beam safety devices protect the work area against unauthorised access from outside. Two cross-connected light barriers in front of each robot PRK sensors reliably detect an incoming pallet. They then start the muting function, which briefly bridges the safety light curtains so that the pallet can pass through.

Clean bottles by express

Empty crates of beer first pass through a special cleaning machine. The previously removed bottles end up in a large bottle washer that can clean up to 72,000 bottles. Here too, Leuze sensors are indispensable for a safe process: The sensors of the PRK series immediately detect when a bottle is out of line on the bottle washer. Then they stop the machine. Safety light curtains also monitor access here. After cleaning, each bottle is checked for residue. If there is still residue in the bottle after the first run or labelling residue is still stuck to the outside, the bottle goes through the cleaning process a second time. If the result is not as required, it is rejected.

Fill fresh and check

Once the bottles are undamaged and completely clean, it's time to fill them. Leuze sensors also make it possible to regulate the belt speed here. The system calculates the optimum speed based on the distance between two bottles. Up to 66,000 bottles per hour are filled with beer in the returnable bottle system. That corresponds to 3,300 crates. The swing-top bottle line operates on a separate production line. It fills 30,000 bottles per hour, i.e. 1,500 crates per hour. A camera system then checks whether the quantity of bottles is correct. After capping PRK sensors recognise whether each returnable bottle has been correctly fitted with a crown cap or whether the swing-top bottle has been correctly sealed. is ready. Labelling follows: the bottle is aligned and the neck, belly and back labels are affixed. Here, too, nothing is left to chance: While still in the machine, each label is checked to ensure it is correctly positioned on the bottle.

Every box in view

The packer then takes over. The machine fills several crates with 20 beer bottles each at the same time. Leuze sensor technology is also used at this station: „During the crate full check, sensors detect in fractions of a second whether a crate is completely full,“ explains Andreas Eberle. „If a bottle is missing or lying crosswise, the crate is sorted out and the error is corrected manually by an employee.“ When crates are filled with swing-top bottles, they are also labelled in a visually appealing way. LeuzeSensors recognise the labels on the bottles and help the machine to position them correctly. In a final step, the crates are placed on pallets and delivered. Here too, sensors are used to detect the presence of the pallets and optimise the material flow.

More news from the magazine

Translucent paper seal labels for pharmaceutical packaging

Packaging machine manufacturer in flow

Powerful automation for mills

Decentralised signal processing with the Schmersal Safety Fieldbox