Sustainability starts with engineering. The cooperation between machine manufacturer Kröning and drive specialist LinMot shows what this approach can look like in a specific application.

The appearance and sustainability of a product are increasingly playing the role of a decisive purchasing impulse. Consumers are increasingly moving away from the „take, make, throw away“ mindset and are turning to products that are sustainable in accordance with the new Directives 2005/29/EC and 2011/83/EU of the Consumer Protection Regulation and favour those manufacturers that can demonstrate ecologically, economically and socially sustainable production environments. However, many decision-makers are also aware of the growing importance of environmentally friendly product design. According to a DS Smith survey, the majority of company representatives consider packaging to be an important area of investment (51 per cent). When asked whether investment in packaging would help efforts in the area of sustainability, as many as 80 per cent of respondents answered in the affirmative.

Application in many industrial fields

Stefano Rossi, CEO of DS Smith Packaging: „Consumers want less packaging. As raw materials are more expensive than ever and the environmental benefits are significant, customised packaging (...) is more important than ever.“ The packaging industry's machine technology must also do justice to this advance in individualised product diversity and the upheavals in industrial policy. This could well be the credo of special machine manufacturer Kröning, whose automation systems combine the latest scientific findings from the Fraunhofer Institute and the Technical University of Dresden with linear drive solutions from LinMot.

„At the beginning of our collaboration with LinMot, the P01 short motors particularly appealed to us,“ says Christian Wölle, Head of Design at Kröning. He particularly emphasises the practical flange design of these short drives. However, this not only benefits special packaging lines. Whether for handling, filling, inspection, feeding, assembly, stacking, sorting or rejection systems, the freely positionable cable outlet of the P01 series and the compact and robust design of the entire LinMot drive range offer a wide range of applications. optimised design of a sustainable machine concept with a small footprint and reduced dead space in every industrial field.

Performance and space utilisation combined

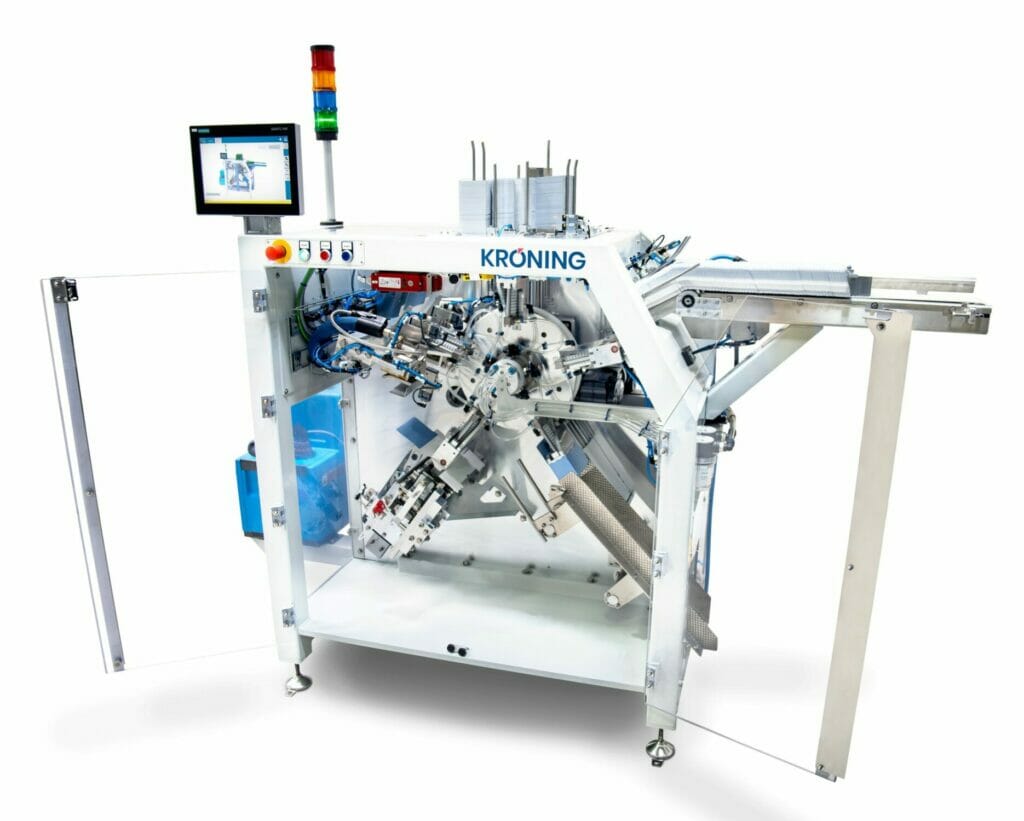

The space-saving and dynamic properties of the ironless synchronous servomotors and their guide units were also decisive for a new development from the Saxon special machine manufacturer. The „KKA“ carton erector from Kröning replaces an outdated system with various cam discs and mechanical connections with the compactness of a central rotary drum cam table. This means that the KKA, with an output of up to 95 cartons per minute, its compact dimensions (1.7 x 1.1 x 1.9 m) and the low weight of 1600 kilos for the basic machine, combine the speed of a large system with the footprint of a mobile solution. The newly developed LinMot linear modules with their modular principle also played a decisive role in this: „At the beginning of 2019, we were only working with the motors and we were still building the guides ourselves. That's why we were really looking forward to the new DM01 line, which gave us a lot of freedom in terms of modularity during the development of the carton erector,“ says Wölle about the design adaptability of the LinMot linear guides, which perform two technically demanding work cycles of the system.

In the first work cycle of the KKA, the jewellery flap is rotated onto the head by a servo motor. This head has various suction points, which in the next cycle are guided through a DM01 module certified for cleanroom applications to the cardboard blank in order to suck it off and bring it together with the jewellery flap. „The movements of the machine and the required dynamics could also be realised with pneumatic cylinders, but only with a large number of different attachments„, explains Wölle, emphasising one of the advantages of LinMot linear guides: The FDA-compliant and highly dynamic DM01 modules are pre-assembled, ready-to-install units with all the design advantages of a modern drive technology package.

All-rounder in any production environment

The compact design of LinMot guide units, which simplifies and speeds up the integration process in production machines of all types and industries, stands out in particular. In addition, both the load and the module can be mounted precisely in no time at all thanks to the centring holes in the front plates and the guide block. Hardened, hard chrome-plated guide shafts as well as easy-to-maintain and easy-to-clean aluminium guide blocks and covers contribute to the stable absorption of lateral forces and bending strength.

In the next cycle, glue is applied to the flaps. In the following step, the folding shaft is located, which is moved by a slider-crank system that folds the blank around the head. In the next and final work cycle, the linkage moves in the direction of the discharge chute and the cardboard is pushed off the head by the second LinMot DM01 module. The particular challenge of special machine construction is that every system is a certain engineering experiment, the success of which depends heavily on the performance spectrum of the functional modules used: „As a special machine manufacturer, our demands on third-party systems are very specific and the realisation of an orderly ejection process is no exception. But thanks to the programmable electric actuators from LinMot, we enjoy great freedom in terms of end position, speed and acceleration, which can be varied over the entire stroke length„, says design manager Wölle.

LinMot offers several series of ready-to-install linear systems, which are capable of designing countless motion sequences depending on the customer's application requirements, precisely to cover such specified and growing requirements. The numerous strength classes, sizes and stroke lengths as well as additional options developed specifically for the industry, such as a completely flushable motor interior for clean-in-place and sterilisation-in-place cleaning processes, 1.4404 (AISI 316L) stainless steel versions, the fully encapsulated stator or stroke lengths up to 2 metres make LinMot linear guideways an all-rounder in any production environment.

More news from the packaging technology sector

Efficient logistics on five wheels

Herrmann Ultraschall appoints Jörg Zech as COO

Food packaging between product protection and the circular economy

Traffic lights prevent bottlenecks