Getecha GmbH was founded in 1956 by Ernst Rosenberg and is headquartered in Aschaffenburg. Today, the family-owned company is one of the leading manufacturers of size reduction systems for the plastics processing industry in Germany.

Getecha develops and produces Plastic granulators for decentralised and centralised use, innovative sprue removal systems, CD and DVD shredding systems as well as complete automation solutions for the processes of feeding, inserting, removing, packaging and palletising as well as regrind conveying and big bag filling. The company currently employs 65 people, has a branch in the USA and generated a total turnover of around 8.5 million euros in the 2016 financial year.

Its customers include users and machine builders in injection moulding, extrusion, blow moulding and thermoforming technology, as well as well-known recycling companies. The company is also an interesting partner for automation specialists in the plastics industry. The management is in the hands of Christine Rosenberger (technology and development) and Burkhard Vogel (sales and marketing). Eva Rosenberger is the authorised signatory responsible for finance and purchasing and is a partner in the company together with Christine Rosenberger.

Burkhard Vogel joined Getecha in 2002 and took over as Sales Director in April 2004. In this interview, he talks about the Development and focus of the company.

pj: Mr Vogel, looking back on the development of Getecha particularly close to our hearts?

Burkhard Vogel: It fills me with a certain pride that we have managed to establish ourselves in Europe as one of the leading manufacturers of energy-efficient shredding solutions for the plastics processing industry. The fact that we have also been increasingly in demand for a number of years as an automation specialist for production-related removal, shredding and return processes, including regrind conveying and big bag filling, also makes us very satisfied - and optimistic. Both are by no means a matter of course for a medium-sized plant manufacturer of German origin.

pj: What events have had a decisive influence on this positive development of the company?

Burkhard Vogel: When our company founder Ernst Rosenberger decided to become an independent entrepreneur as a young engineer in 1956, he actually wanted to concentrate purely on development work in his garage at home and also do a little machine trading. He did not initially think about setting up his own production facility. But things turned out differently. At the beginning of the 1960s, the first production and assembly hall was built at the current Aschaffenburg site, and a little later, further warehouses were built to optimise procurement logistics. This laid the foundations for the operational infrastructure for the development and manufacture of high-performance granulators for the plastics processing industry.

pj: Can you say at what point the company's transformation from a pure mill builder to an automation specialist with its own project engineering began?

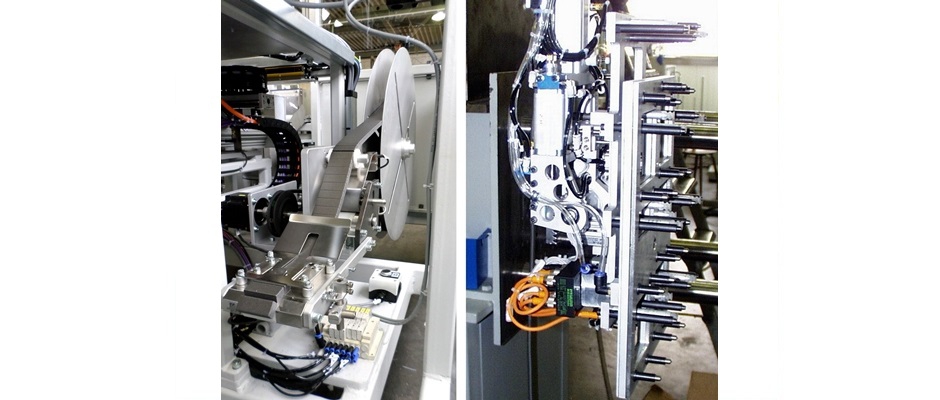

Burkhard VogelYes, there were actually the first signs of this quite early on in the company's history. In the 1970s, when the Danish toy manufacturer Lego asked us to automatically transfer the sprues from its injection moulding machines to the granulators, we started developing and producing fast electro-pneumatic sprue pickers and removal systems. This was the first step on the road to automation. Today, with the help of modern linear and control technology, we realise in this area sometimes Highly complex multi-axis systems with excellent positioning and repeat accuracy.

Another important event on the way to becoming an automation specialist was the Rejuvenation of the management by the entry of the founder's daughters: Christine Rosenberger as Managing Director for Technology and Development and Eva Rosenberger as authorised signatory for Controlling and with responsibility for Purchasing and Accounting at the end of the 1990s. I myself joined Getecha in 2002 and took over the management of sales in April 2004.

Two years later, we then bought a new logo and a Modernised company image given - especially in order to Reorganisation of the company to express this. Since then, we have not only been driving forward the development of modular and energy-efficient granulators, but are also increasingly recognised by plastics processors as a manufacturer of individual, customer-oriented size reduction and automation solutions.

pj: Where do you see Getecha's strengths today - also in terms of differentiation from the competition?

Burkhard Vogel: Today, it is no longer enough to simply supply reliable and efficient granulators. Customers - whether domestic or international - now expect much more. They want a partner who can offer them more than just shredding technology. Customised and highly automated complete solutions including the feeding, removal, conveying, packaging and circulation systems. The way Getecha is organised today, we can offer this. And that for All areas of the plastics processing industry from injection moulding technology and thermoforming to blow moulding technology and plastics recycling. Our great strengths lie not only in our expertise in plant and control technology, but also in the intelligent combination of modern shredding technology with all types of conveying, handling and packaging peripheral systems. This is precisely what sets us apart from many of our competitors.

pj: Are there any changes or trends in the relationship between you as a plant manufacturer and the customer?

Burkhard Vogel: Yes, we are observing in particular an increasingly clear Splitting the clientele into two groups. One group only buys on the basis of price and relegates even qualitative aspects to second place. It mainly uses the product range of Asian suppliers. The other, somewhat smaller group, on the other hand, favours high-quality engineering, focuses more on the added value of an overall system solution and also uses the overarching approach of the Total cost of ownership (TCO) as a decision-making basis for their investments.

We feel a closer connection to the customers in this group and their usually long-term co-operation. This is also due to our own self-image: despite the international nature of our sales organisation, Getecha is a down-to-earth family business that is there for its customers. It is not crucial for us to have an unmanageably large number of customers. It is much more important for us to be able to look after each customer so attentively that a trusting, sustainable partnership develops. Our actions are based on this customer-orientation and we always strive to create genuine win-win situations.

pj: What considerations are currently guiding you in your product developments?

Burkhard Vogel: For some time now, the main aspects of technology have been Energy efficiency, environmental compatibility and system integration, which guide our development work. We are also currently realising numerous design ideas that will reduce maintenance costs for the customer and further simplify the operation of the machines. Many of the current shredders and system components are being modernised accordingly. We also see the following as key success factors that apply across all our RotoSchneider series Flexibility and modularity of our machines. These two aspects in particular ensure that we can quickly and easily customise any large central or small beside-the-press granulator to the customer's requirements - also with regard to their integration into complex overall solutions and their connection to the customer's higher-level production control systems.

pj: What was the public's response to the innovations presented at the K plastics trade fair in October?

Burkhard Vogel: We brought some innovations with us to K in Düsseldorf. Especially those that significantly simplify and improve the integration of our RotoSchneider granulators into our customers' production lines. The systems have been further developed, particularly in the area of thermoformed packaging and edge trim preparation in the associated film production. The inline infeed machines can process the solid films, the moulded articles in the films and, of course, the die-cut strips up to a film width of 1,750 mm. About the Energy-saving controller the required output of the machine and thus the consumption are adapted to the respective situation. In the edge trim mill, the bow control is no longer required and the tractive force on the edge trim can be adjusted as required. In addition, the external Design of the machines to create a nicer and more pleasant working environment for our customers' employees.

pj: Are there any political developments that you and the Getecha management are concerned about for the future?

Burkhard Vogel: Yes, but they are not new and affect almost all sectors of industry. We are actually always latently concerned about certain forces that oppose the use of plastics across the board without recognising the many ways in which these materials make our lives easier today. In our view, „plastic bags in the sea“ type campaigns against the plastics industry completely miss the point. The question here is rather: „Who threw the bag into the sea?“ We must finally put an end to the wild disposal of waste. Everyone must be concerned that all recyclable materials are returned to the production cycles become.