The combination of an X-ray inspection system and a checkweigher from Ishida enabled the British contract packer UFP to implement a new packaging solution for a major customer.

Universal Flexible Packaging (UFP), based in Leicester, UK, is a long-standing partner of the Itsu brand, which specialises in Asian-inspired foods. The manufacturer was looking for a new packaging solution for its premium noodle range. New cups with metal foil lid to make the packaging process more efficient. Conventional foreign body inspection with metal detectors was therefore out of the question. The optimal solution for this task was an X-ray inspection system whose detection performance is not impaired by the film. The system also identifies non-metallic foreign bodies such as glass, ceramics and stones. Although the latter only occur very rarely in the pasta products, UFP thus achieves a further quality assurance level in accordance with BRC AA+ certification.

Reliable foreign object detection without tipping over

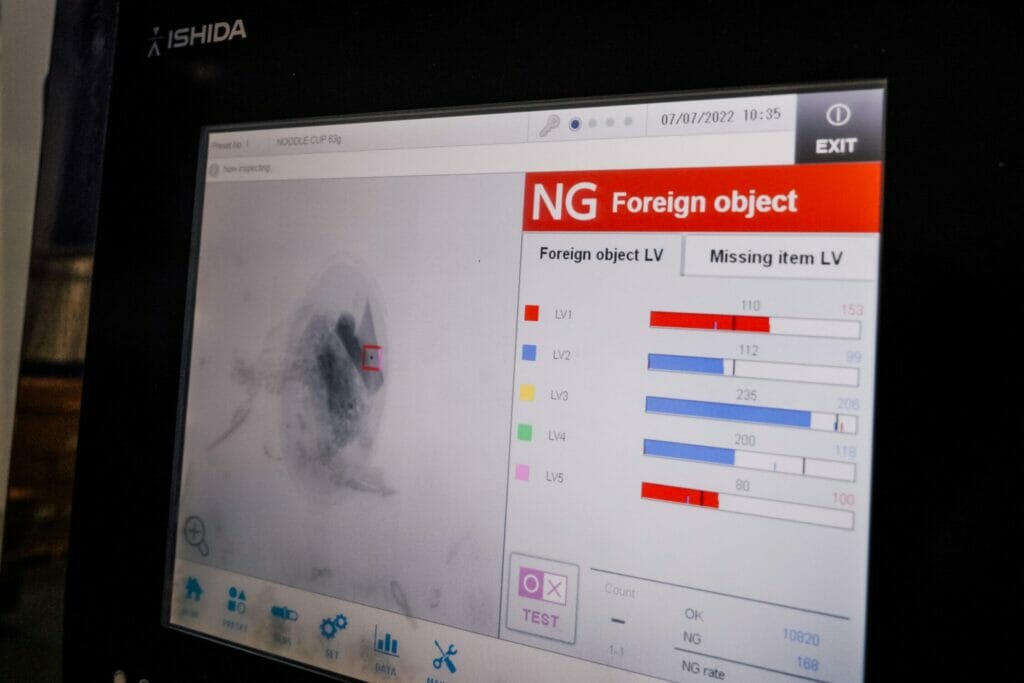

UFP decided in favour of an IX-EN-2463 X-ray inspection system from Ishida. „We have been working successfully with the manufacturer for a long time and this entry-level model was the right solution for our application,“ says Steve Potter, Technical Manager at UFP. The Ishida device was specially developed for the inspection of light and comparatively homogeneous products. For foreign body inspection, it measures the density by passing the X-ray light through the cups and recording it with photodiodes. Depending on the level of X-rays received, a greyscale image is created that shows inclusions with a greater density than the product itself as dark spots.

The patented technology of the IX-EN-2463 is based on software with a learning genetic algorithm. Very high accuracy is achieved by analysing image data over several generations. As recurring contamination usually occurs in food production, it is possible to a more precise protocol for the comparison with each test procedure create.

Before installation, a special challenge of the UFP application had to be overcome. The lightweight cups can tip over when entering the test chamber of the device due to contact with the protective curtains. The IX-EN-2463 X-ray inspection system works with comparatively low voltage of 50 kV and Ishida equipped the device with a feed tunnel as an alternative protective device.

The foreign body check is followed by a final check of the weight of the cups to ensure that all ingredients are present. The DACS-G high-performance checkweigher has the following features an exceptionally fast and accurate digital load cell developed by Ishida, that works reliably even in challenging production environments.

You can switch between two weighing ranges at the touch of a button, allowing you to flexibly process a wide range of products with different packaging formats can. The integrated Retail Reject Confirmation (RRC) software enables proof to be provided to retailers that all products that do not meet the specifications have been removed from the packaging line. The packaging rejected by the X-ray inspection system or checkweigher is collected in reject bins.

UFP processes with the new quality control systems Two cup formats with a speed of around 80 cycles per minute, The system is in operation around the clock, five days a week. „The Ishida systems have made a significant contribution to increasing efficiency following their smooth integration into our packaging line. They are very reliable and easy to operate,“ says Steve Potter.

Source: Ishida

Ishida - More news

New traysealer from Ishida

Ishida shows laser technology against leaks

High-speed filling

Packaging Valley presents Fachpack appearance