What facts do consumers still not know about the good old tin can? The manufacturer thyssenkrupp Rasselstein provides answers on its online platform „Tinplate comes next“.

„8 unusual facts about food cans you didn't know!“. Under this title, thyssenkrupp Rasselstein explains on its Online portal for consumers Things that perhaps not everyone knows.

8 unusual facts about food cans that not everyone knows

Although the food can was invented by Peter Durand in 1810, can openers were not invented until many years later. At first, brute force or a hammer and chisel were all that was needed to open the cans. It was not until 1870 that the can opener with a cutting wheel was patented. Today, many food cans have ring-pull lids that do not even require a can opener.

Although the food can was invented by Peter Durand in 1810, can openers were not invented until many years later. At first, brute force or a hammer and chisel were all that was needed to open the cans. It was not until 1870 that the can opener with a cutting wheel was patented. Today, many food cans have ring-pull lids that do not even require a can opener.

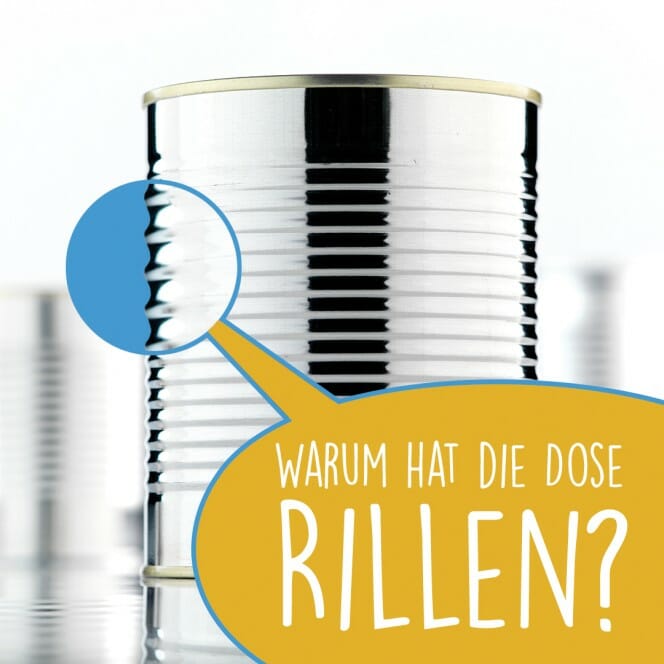

If food is canned fresh from the field, it should last as long as possible. This is why the filled and sealed cans are heated to over 100 degrees. This process automatically kills bacteria. After sterilisation, the can cools down to room temperature. This creates a vacuum - without the corrugations, colloquially known as „grooves“, the can would collapse. The corrugations therefore ensure that the can can expand and contract again without breaking.

A standard food can has a diameter of 73 millimetres and can be loaded empty with a load capacity of approx. 2.3 kilonewtons until it is irreversibly deformed. Converted, this is 4,545 times its weight!

While the three-part can traditionally consists of a body, lid and base, the body and base of the two-part can are made from a single piece, i.e. the can lacks the classic vertical weld seam and the lower seam connecting the body and base. This increases the quality of the can, as these areas can be critical points of attack for corrosion.

According to the German Metal Packaging Association, around two billion food cans are sold in Germany alone every year. Tinned fish and seafood, such as tuna or herring in tomato sauce, as well as fruit and vegetables account for a third each. 15 per cent of these are ready meals such as soups and stews.

The tinplate packaging recycled each year could be used to produce enough steel to build 27 Eiffel Towers. This illustrates the enormous potential of the recycling process. In fact, the melted material can also be used to make any other new steel product, from bicycles to wind turbines. A calculation by the German Steel Federation has shown that 84 per cent of the steel ever produced is still in circulation today. This is called the circular economy.

There is an amazing variety of products that are sold in tins. Around 1,500 different foods, from vegetables, meat and fish to desserts, fruit and truffles - the choice is endless. Whether you prefer something savoury or sweet, there is sure to be a canned food that suits your taste or that you have never eaten before.

Real can lovers may know that it all started with Napoleon. He promised 12,000 gold francs to anyone who could develop a solution for permanently preserving food for the troops. In doing so, he laid the foundation for the triumph of the tin can.

More news on the subject of cans

The spray piece - Refill by Respray Solutions

The can holder from Smurfit Kappa

Can printing: small quantities plus deposit label

Continuation of long co-operation