Sappi has entered into a development partnership with digital printing pioneer Xeikon. Together, the partners are taking an important step towards direct printing on paper-based materials and the recyclability of the resulting flexible packaging.

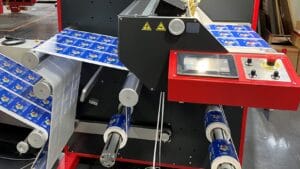

Digital press manufacturer Xeikon, part of the Flint Group, has now launched its latest toner innovation Titon and the Xeikon TX500. has set its sights on the market for paper-based flexible packaging. This is experiencing strong growth due to the demand from end consumers and thus from brand owners and processors for resource-saving, recyclable and plastic-free alternatives.

The requirements for the Inks for direct printing on paper-based materials for applications in the field of flexible packaging, e.g. for food packaging such as that offered by Sappi, are high.

„Apart from the fact that they need to deliver a good print result, the colours must be particularly resistant throughout the packaging process and must be temperature-resistant, e.g. for heat-sealing. They must also be odourless, tasteless, food-safe and migration-proof, especially for applications in the food sector.“

Frank Jacobs, Market Intel & Senior Product Manager at Flint Group Digital:

With Titon, Xeikon is meeting the industry's need for environmentally friendly and product-safe packaging production: The new toner formulation combines the best properties of toners and UV inks. It combines the food-safe and odourless properties of dry toner with the special resistance of UV inkjet ink to chemicals and mechanical abrasion. It can also withstand temperatures of up to 220-260°C - essential for the integrity of the packaging and the protection of the product. The most important feature of the new technology: thanks to the special formulation, Titon can be used to print directly onto paper-based packaging materials, without the need for additional varnishing or lamination to protect the print.

Problem-free recycling in the paper waste stream

An innovative toner like Titon works best when the substrate used is just as innovative and perfectly matched to the respective application. So it made sense to test the new technology with Sappi products. Since Start of cooperation at the end of 2022 extensive tests revealed two qualities in particular that harmonised especially well with the toner.

„With our innovative functional papers Sappi Seal Silk with a basis weight of 67 g/m2 and Sappi AvantGuard S Natural with a grammage of 75 g/m2 we have achieved the best printing results. Both papers have a particularly high-quality appearance and were specially developed for the flexible packaging market.“

Sibylle Hajostek, Market Manager Packaging Solutions at Sappi

The one-side coated, heat-sealable Seal Silk is particularly recommended for flexible standard packaging in the food and non-food sectors, while the uncoated, heat-sealable high-barrier paper AvantGuard S Natural is equally suitable for various flexible packaging applications in the food and non-food markets.

The results of the tests with both brand owners and processors were so convincing that Xeikon's customer ACM Plastic in Italy has since permanently produced with barrier papers from Sappi. In addition, initial tests are underway at ACM to put another Sappi quality, AvantGuard S Gloss, through its paces.

Thanks to Titon technology, additional processing steps are no longer necessary. Combined with the recyclable, paper-based solutions from Sappi, a Complete recycling of all packaging in the paper waste stream and subsequent utilisation, e.g. for corrugated board applications, is possible without any problems.

As numerous tests have shown, the technology all criteria of the Nestlé Standard on Printing Inks for Food Packaging, the EuPIA Exclusion Policy for Printing Inks, the Swiss Ordinance, the German Ink Ordinance and other migration tests. This makes the combination of Titon technology and Sappi's paper-based solution ideal for a wide range of applications with direct or indirect food contact. The two cooperation partners supported brand owners in their endeavours toThe company is now switching to paper-based alternatives for packaging food, z. e.g. flexible packaging for baked goods, confectionery, sugar, flour, herbs, spices and tea.

The technology even opens up new areas of business for print shops and processors: Applications that were previously only possible with conventional flexographic printing presses can now be now faster and more flexible thanks to digital printing are covered. With the TX500 - a new member of the Cheetah series - Xeikon recently introduced the first digital printing press to work with Titon technology.

Source: Sappi

Xeikon - More news

Sappi and Xeikon present paper-based candy packaging

Partnership for digital label production

Xeikon launches eco-toner on the market

Digital printing for flexible paper packaging