The Lower Saxony-based start-up Papair has launched a double-layer bubble wrap made of paper onto the market. Using a patented process to produce the sustainable packaging material, a pilot plant was recently launched at the company's own production site in Rethem an der Aller.

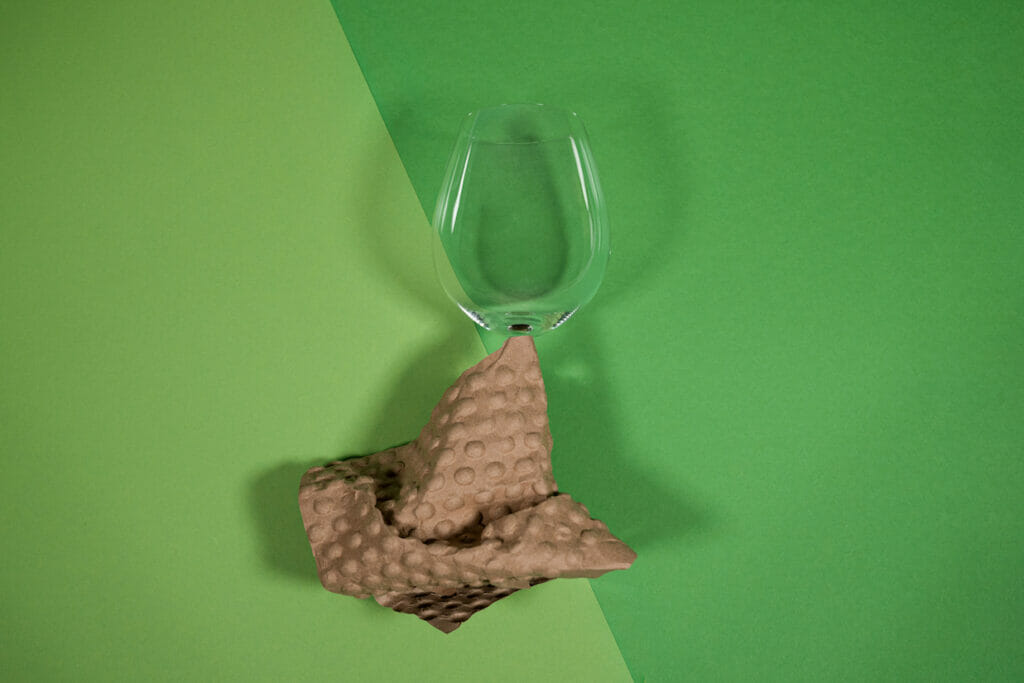

PapairWrap is the name of the new bubble wrap made from 100 per cent paper that does not require any plastics or adhesives. A pilot plant has recently started producing it using an innovative manufacturing process the two-layer padding material made of paper. The process was developed by the three founders of the start-up Papair. Christopher Feist, Fabian Solf and Steven Widdel wanted to create a new alternative to conventional packaging materials with their product. The founders have patented the manufacturing process.

„There was no technology like this before. With the pilot plant, we have already tested whether the process works in small steps and are ready for the large-scale plant.“

Christopher Feist, CEO and co-founder

The innovation: „Until now, padding film made of paper has always been single-layered. Our product is now double-layered for the first time and therefore offers better stability than other padding materials made of paper. What's more, PapairWrap doesn't require any plastic or glue - which also saves costs.“

Start with pilot plant

The start of production was planned for March 2022, but the pandemic and global political events repeatedly delayed the delivery of technology and components for the plant. After an extensive commissioning phase at the mechanical engineering company in Bavaria finally got underway at its own site in Rethem an der Aller in 2023.

The founders had previously presented their innovative product at various trade fairs such as Fachpack, Empack Hamburg and the Hannover Messe. The PapairWrap from the first system will initially be supplied to over 150 customers from various industries. Parallel to this pilot projects with selected customers, to evaluate the use of PapairWrap and incorporate the results into further development.

„So far, most customers have approached us and together we then look for the optimum solution. Some customers send us their products and we then make suggestions as to how they can be packaged with PapairWrap.“ Demand is high, because many companies want to switch from plastic to paper. „The order situation is very good, the first lorry with PapairWrap has just left our plant for Switzerland.“

The pilot plant currently produces around 50,000 square metres per month. „The large plant, which we plan to put into operation at the end of 2023, will then 800,000 square metres per month create. Then we will also be able to, offer two different product widths - 35 and 80 centimetres. In terms of price, we will be able to keep up with comparable plastic products. We can probably even undercut them if you take into account legal regulations such as plastic taxes in the UK or Spain or the licence costs stipulated by the Packaging Act. The disposal costs for our paper product are also more favourable than for plastic cushioning film.“

Expansion of the portfolio planned

The production launch of PapairWrap was an important milestone, but the team and the founders are already thinking ahead. Financing must be secured for the purchase of further systems. The three had financed the company launch via crowdinvesting and raised a considerable amount of money from non-bank backers via the internet right from the start. „We only had an idea at the beginning, and in order to remain independent, it was not an option to look for investors straight away,“ says Christopher Feist. „We don't originally come from the paper or packaging industry. During my studies, one of my co-founders had the opportunity to take part in a start-up course. And through his family, we learnt about the problem of the industry using far too much plastic for packaging. That's how the idea for PapairWrap was born.“ The sustainable cushioning material can do much more, because the Papair team is already working on further functionalities for the bubble wrap, to expand the product portfolio. Specifically, these are sustainable shipping bags, padded shipping boxes and customised special products.

Already honoured several times

Founded in 2020, the start-up has set itself the goal of avoiding plastic waste and bringing a packaging material to the market that combines safety, cost efficiency and sustainability with its bubble wrap made of paper. The success proves the team and its vision right. In December 2022, they were with the Lower Saxony Breakthrough Award in the Newcomer/Scale up category was honoured. They also made it to the final of the Lower Saxony Innovation Award and the international Sustainable Packaging Award.

Since 2023, they are also Part of the Amazon Sustainability Accelerator. „We are one of the 16 selected companies that receive coaching, workshops and financial support. We are currently learning a lot there and are learning from the Amazon standards that exist in the USA, for example, that facts and figures are important if you want to be successful,“ says Christopher Feist. „I hope that in future it will be less important to always have a 100 per cent solution at the ready, especially when it comes to sustainability. You often miss the mark with this claim, because the perfect solution is not always immediately available. But we need change, and if you have a good idea, you should just get started."

E-Commerce - More news

Mondi develops recyclable paper packaging for bicycles

Top Ten 2025: Smurfit Westrock closes plants in Hanau and Lübbecke

VPK Group increases stake in Ribble Packaging

Hinojosa takes over French ASV Packaging completely