COSMO CONSULT is one of the largest Microsoft Dynamics 365 partners in Europe and supports numerous international customers with Microsoft Dynamics products with more than 1400 employees. We have been a partner to the printing and packaging industry for over 20 years. In the process COSMO printing and packaging proven in many successful projects.

Product overview

An investment- and future-proof industry software solution

Based on the standard ERP software Microsoft Dynamics 365 Finance and Supply Chain Management COSMO CONSULT has developed the industry software solution COSMO printing and packaging developed. It supports all common printing technologies for the production of folding cartons, labels, flexible packaging, corrugated packaging, displays and web printing. Product finishing processes such as laminating, embossing, foiling and others are just as much a part of this ERP industry solution as the process stages of (roll) cutting, die-cutting, gluing, packaging and finishing.

The solution enables you to fulfil customer requirements more creatively, quickly and reliably in a dynamic market with many competitors. The basis for this is more efficient planning and implementation of industry-specific production processes and the establishment of global IT standards.

COSMO printing and packaging minimises your costs and risks, supports you with optimised resource management and increases your customer satisfaction.

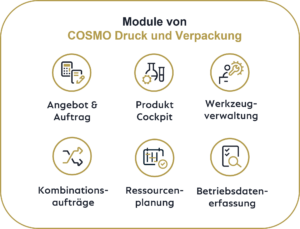

Extract of the modules

Product cockpit

The product cockpit is the centrepiece of COSMO Print and Packaging. All the necessary work steps, settings and required materials are managed here and displayed transparently in an overview. Functional highlights:

- Creating new configurations / products

- Compilation of parts lists with all relevant data, including tools, packaging structures and materials

- Defining work plans taking into account various predefined technologies

- Preparation of cost statements and production orders

Resource planning

The planning control centre, which is fully integrated into the industry solution, provides your production planning with a comprehensive tool for optimising the planning sequence. Regardless of whether the medium-term utilisation of all bottleneck resources needs to be guaranteed or a rush order needs to be scheduled at short notice, the control station offers the appropriate functionalities. Functional highlights:

- Planning phases with different planning horizons

- Multi-resource mode (MRM)

- Simulation of alternative scenarios

- GANTT representation

Production data acquisition

Released orders are displayed with all production-relevant information on the production data acquisition (PDA) terminal for each machine and recorded on it. The work-in-progress functionality (WIP) maps all production steps within a production order. By confirming good quantities between the individual production stages, semi-finished goods are automatically managed in the ERP in terms of stock and value. This enables clear and date-related analyses. Functional highlights:

- Recording of set-up and machining processes

- Quantity and scrap feedback

- Fault detection with times and reasons for faults

- Material and tool assembly

Further information on our other modules can be found on the website.

Our promise - Our ambition

We use the latest technologies and proven standard products from Microsoft, which we optimise according to your specific requirements in order to offer you maximum added value. This "customisation" is sure to provide you with a solution that suits you perfectly. The profitable application is reflected in streamlined business processes that enable you to permanently reduce costs and grow sustainably.

COSMO Print and Packaging can also help your company to streamline processes and thus achieve greater added value. We will find the right options for you in a non-binding consultation.

You are also welcome to read our Industry Guide - Challenges and solutions for the printing and packaging industry