The issue of sustainability has also reached the pet food market and the area of packaging for dry pet food. Traditionally, paper packaging with problematic halogenated fluorocarbons is often used as a fat barrier. Kuraray offers various alternative packaging concepts.

The market for pet food has grown rapidly in industrialised countries in recent years - along with the number of pets. Pandemic restrictions have contributed to the increased interest in pets certainly contributed to this. This has also led to a pet food boom. In fact, the number of packaging units sold for no other FMCG product is growing faster than for dog and cat food: with a compound annual growth rate (CAGR) of around 25 per cent for the period from 2015 to 2020.

Basically take Consumers perceive paper-based packaging as more sustainable. This applies to both human food and animal feed. But for innovative packaging solutions, it is essential that they continue to fulfil all the functional requirements that a food - or in our case, dry food - places on its packaging. This is an inherent challenge with paper-based packaging, as it requires a Reliable barrier against the fat contained in animal feed. Cat food, for example, usually contains 10 per cent fat, while dog food typically contains up to 20 per cent fat.

Special attention to the coating

Traditional paper packaging often realises the indispensable grease barrier in a problematic way: They use fluorocarbons for this purpose. Halogenated plastics such as Fluoropolymers are not permitted in the food industry due to their potentially detrimental effect on the human - and animal - organism. but very controversial. In addition, the recycling of dry pet food packaging containing fluorocarbons is also extremely difficult. In the case of new, more sustainable alternatives to the current packaging for dry animal feed, it is important that they have a similar barrier effect against flavours, odours and grease as established concepts.

Curaray offers paper-based packaging solutions with barriers made from pioneering polymers. The packaging, some of which has already been launched on the market, is suitable for replace old paper and cardboard packaging whose grease resistance is still based on fluorocarbons. based. They combine sustainability and functionality.

Resistant to water, oils and grease

One of the packaging concepts can be described as a paper/moisture barrier coating/EXCEVAL coating/hot seal coating structure. Paper-based food packaging of this type has already proven itself in commercial use. Here the Thin, water-soluble EXCEVAL coating as an oxygen and flavour barrier. EXCEVAL is a halogen-free, hydrophobically modified polyvinyl alcohol (PVOH) from Kuraray that is characterised by special Resistant to water, oils and grease is characterised by. EXCEVAL is applied to the paper using conventional coating systems, such as rotogravure or bar coaters. Dispersions of polyolefin or other polymers are usually used as the heat-seal coating on the inside. The great advantage of these paper structures is that they are can be easily repulped in conventional paper mills. And repulping is a technological approach that has been tried and tested in the paper industry for many years. This would be impossible with fluoropolymers because they are not soluble in water.

Barrier for flavours, oxygen, light and moisture

The company also offers a solution with paper and a vacuum-metallised layer of EVAL and BOPP. EVAL is the name of the ethylene-vinyl alcohol copolymers (EVOH). The film made from EVAL EVOH and biaxially orientated polypropylene (BOPP) is metallised in a vacuum with just a thin layer of aluminium as a barrier for aromas, oxygen, light and moisture. Laminated, simple cast polypropylene forms the sealing layer for the inside of the film pouch. A stenter frame machine takes over the co-extrusion of BOPP and EVOH for the outer layer. This Packaging concept avoids the use of much larger quantities of aluminium in the form of an aluminium foil. Nevertheless, EVAL EVOH is an excellent substrate for the evaporation of aluminium and an extremely reliable aroma and oxygen barrier. The Packaging prevents the oxidation of fats in the dry food.

The vacuum-metallised layer provides a good light barrier and preserves the vitamin C content of the animal feed. This packaging concept uses the smallest possible amount of plastic and at the same time allows optimum repulpability of the paper fibres - in the Washing Step system, they can be easily separated from the small amount of plastics. The reduction in the amount of aluminium deposited on the film also makes the polymers in this paper packaging recyclable.

Technology for multilayer films

Kuraray also offers its customers paper bags with a metallised film layer made of EVAL and MDO-PE. This paper packaging basically follows the same principle as the previous example. The only difference is that this time polyethylene is used instead of polypropylene together with the ethylene-vinyl alcohol copolymer (EVOH). The inner sealing layer is made of polyethylene and a machine direction orientation polyethylene (MDO-PE) is used for the vacuum-metallised film together with EVAL EVOH. In mechanical engineering, the Technology for the production of multilayer films has developed considerably in recent years. This makes a multilayer film with MDO-PE an interesting alternative. MDO technology allows both cast and blown films to be orientated in one direction in order to give the film better properties. This packaging concept prevents fat oxidation and preserves vitamin C in animal feed. The packaging does not require aluminium foil or BOPET, uses the smallest possible amount of plastic and ensures that the paper fibres can be easily repulped.

Paper packaging for repulpable fibres

One packaging concept that is already in use is based on repulpable paper packaging with PLANTIC bioplastic. Here, a PLANTIC film is laminated onto the inside of the paper. Kuraray produces the PLANTIC bioplastic from renewable raw materials, thermoplastic starch. PLANTIC is Biodegradable and compostable (industrial and household). Thanks to its high gas barrier effect, the bio-polymer enables packaging that preserves flavours and effectively excludes oxygen. In this packaging concept, an inner sealing layer is also applied to the PLANTIC film - optionally made of polyethylene, polybutylene succinate or polybutylene adipate terephthalate. This Sealing layer also acts as a moisture barrier. This packaging is produced using technologies such as Extrusion coating, lamination and extrusion lamination for use. In the repulping process, PLANTIC allows the inner sealing layer and the adhesive to be separated from the paper. In addition, thanks to the bio-polymer, the repulping yield is higher than with a conventional PE layer, for example, because the fibres do not penetrate the PLANTIC film. This means that all paper fibres can be repulped without any problems.

Source: Curaray

Author: Dr Bettina Plaumann, Kuraray Europe, Paper & Packaging Segment Team

More news on paper packaging

Nextpack replaces polystyrene with honeycomb cardboard

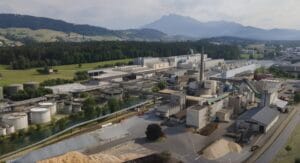

Perlen gets into moulded fibre packaging

Tetra Pak invests in barrier technology

Major order for packaging factory in Egypt