At CPHI in Barcelona from 24 to 26 October, Groninger will be presenting solutions for processing small and very small pharmaceutical quantities, which have become increasingly important in numerous areas of application. The expert for filling and capping systems has responded to this trend and launched corresponding system formats.

Machine concepts for the safe processing of small and very small quantities of pharmaceuticals will be on display at the 80 square metre stand. „Their importance has both in pharmaceutical research as well as in manufacturing and processing has increased significantly in recent years,“ says Dirk Schuster, Sales Manager of the Groninger Pharma division.

So-called „Biotechs“ have gained massively in importance in numerous application areas - often on a patient-specific basis. This means that pharmaceuticals are produced and processed taking into account the genetic, molecular and cellular characteristics of a patient or patient group.

„These treatment methods are tailored to the specific needs of individuals so that they can make the healthcare system significantly more efficient. They are based on the possibilities that modern diagnostics, including genetic diagnostics, offer us today,“ explains the Sales Director. A development that will not only benefit the pharmaceutical industry itself, but also also poses new challenges for manufacturers of filling and packaging machinesWhile for many years in the past it was mainly systems for processing so-called blockbusters - i.e. systems that process large quantities of frequently used medicines such as vaccines quickly and cost-effectively - today it is often small and very small batches that need to be filled as safely and efficiently as possible.

Groninger responded to this trend a few years ago - and launched corresponding system formats, which the mechanical engineering company is presenting at CPhI. Among other things, modules from the so-called labworx series will be on display. The complete filling and sealing process can be mapped on these semi-automatic table-top machines. The special feature of these modules: With the labworx series The same technologies, processing methods and components are used as in high-speed filling and capping systems from Groninger. In this way, important findings and data obtained during the development process can be quickly and easily scaled up to larger filling volumes and systems.

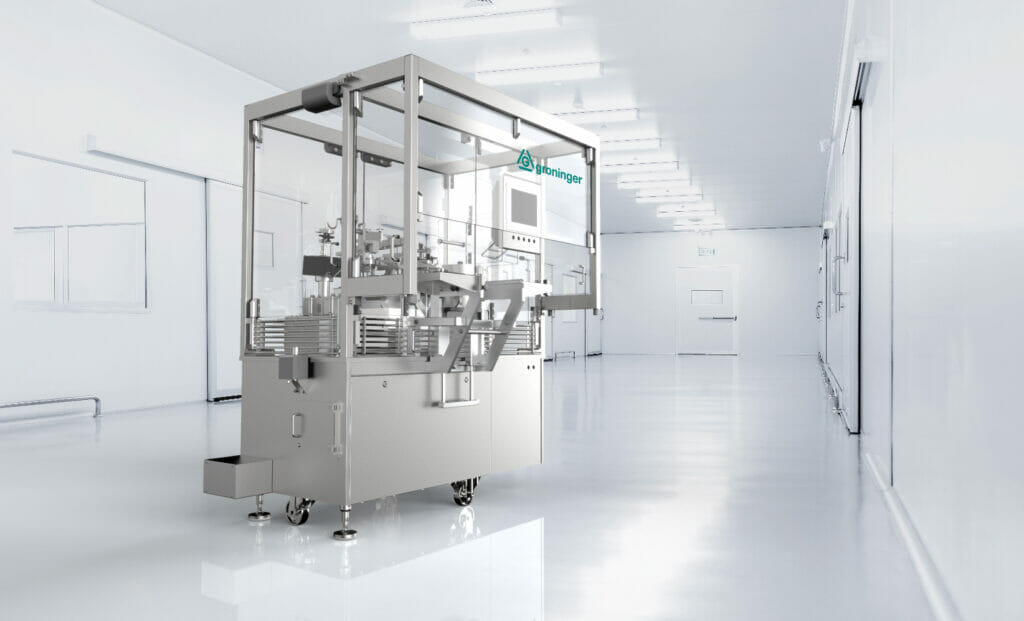

In addition, the „DFVN 1005V“ compact system is a filling and sealing system for pre-sterilised objects in the nest for laboratories, test series and small batches. Just like the labworx series, the DFVN identical processes to a high-performance system. Here, Groninger relies on a mixture of manual handling and a fully automated production area: automatic removal of the nest from the tub and placement in the centring frame or insertion and removal through a lockable opening in the machine guard are carried out manually. Transport to the filling and tamping station and back again, on the other hand, is fully automated. Over 10,000 objects can be processed on this system every hour.

„With these exhibits, we are providing an insight into what is already possible today in the field of small and very small batches - without pharmacists having to compromise on the quality or safety of processing.“

Dirk Schuster, Sales Manager of the Groninger Pharma Division

Source: Groninger

Groninger - More news

Intelligently filled and sealed

Groninger: Focus on small pharmaceutical quantities

Groninger invests in US site

New CEO at Groninger USA