Depending on the order, customers place different demands on their tools. Marbach offers suitable technologies for individual requirements for blanking in packaging production.

„The trend towards automated blanking continues unabated: This is because, compared to manual separation after the die-cutting and stripping process, automated separation ensures greater productivity in the entire postpress area. As the requirements of orders and packaging manufacturers are very diverse, we have various solutions for blanking.“

Bernhard Reisser, Industry Manager Folding Carton at Marbach

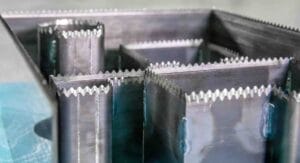

The Marbach alublanker is a depanelling tool lower part. The separating grid is made of aluminium and is completely CNC-machined. It is characterised by its Precision and its low weight out. This is because the alublanker is more than 50 per cent lighter than a conventional compact blanker. This makes it possible for a single machine operator to install the tool in the punching machine.

„Not having a second person saves our customers time and money. But of course, productivity is also very important to our customers. Thanks to its high precision, the alublanker also offers a number of advantages in this respect: It stands for perfect stack formation, reduced set-up times, high packaging quality without imprints and high machine speeds.“

Bernhard Reisser

The lightblanker is a modular depanelling tool in which the base frame can remain in the machine. It is not only lightweight, but also inexpensive. It therefore pays for itself very quickly with short runs and simple layouts. The base frame can remain in the machine. It is Adapted to the order-related separation mask for each application. A few simple steps and the lightblanker is ready for use. The lightweight is characterised by its quick-release fastener and one-man handling as well as its flexibility and quick conversion to sheet storage.

The marbablanker is suitable for repeat orders. It is customised to the customer's requirements, lightweight and stable at the same time. As the Mould frame designed individually for each order and firmly connected to the actual separating mask the marbablanker ensures short set-up times.

The compact blanker is the origin of the Marbach blanking tools. The lightblanker and the marbablanker were developed on its basis. It is made of steel, solid and massive. It is customised for each individual customer order and stands for fast production processes.

Source: Marbach

Further news from the company

Anniversary in Poland

Special tools punch honeycomb cardboard

Developments for maximum performance

Innovations around punching