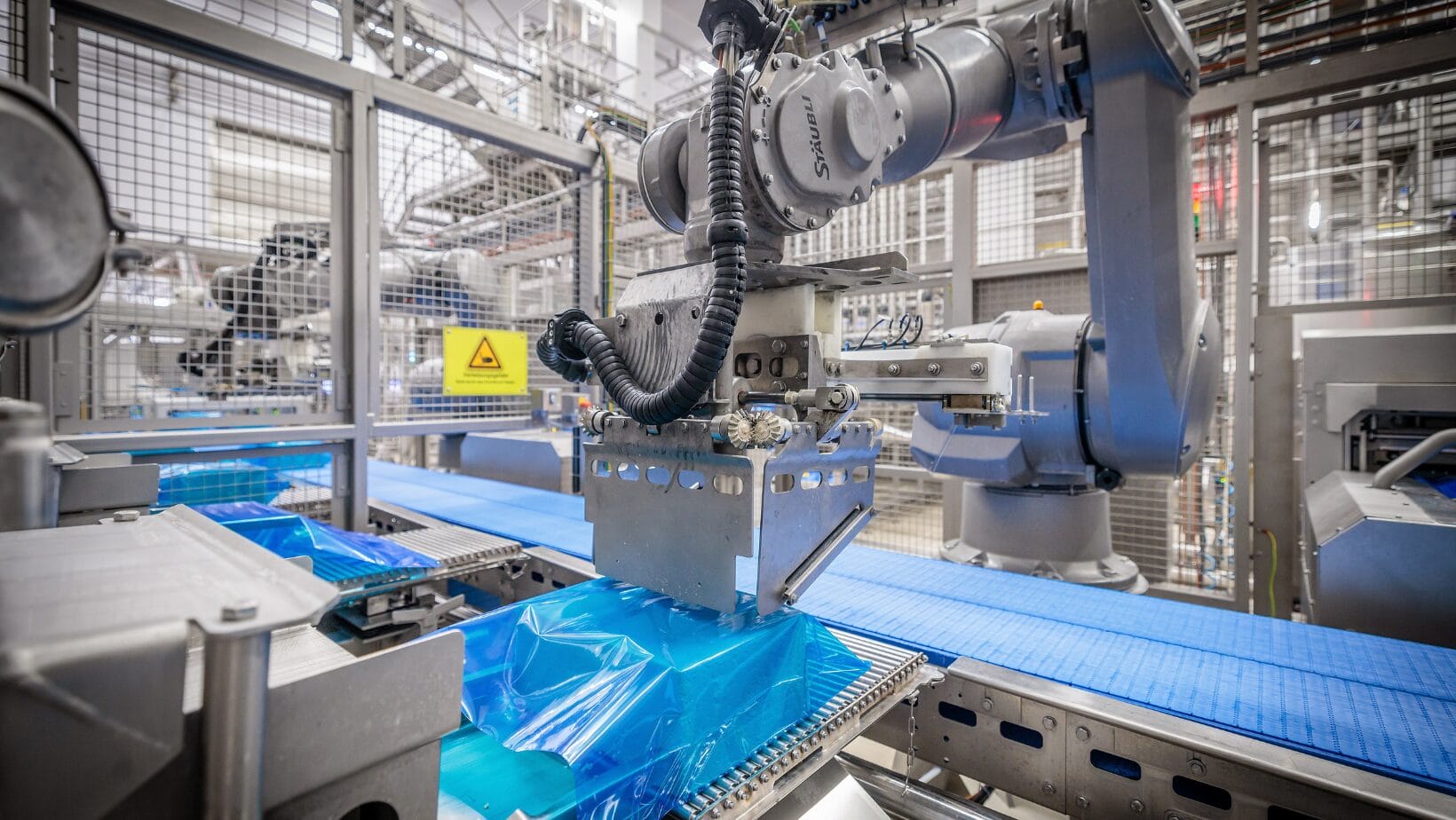

Stäubli Robotics' automation solutions for the food industry cover a wide range of applications - in processing as well as in the primary and secondary packaging of food. The hygiene-compliant robots help users to meet even the strictest safety requirements and quality standards while optimising their processes and increasing productivity.

At Anuga FoodTec in Cologne, Stäubli specialists from the food industry will demonstrate “live” how food manufacturers can automate their production lines and thus strengthen their competitiveness. Together with partners in the food industry, Stäubli is working worldwide on the Development of robotic systems that automate processes in primary and secondary processing. The robots are used for tasks such as cutting, boning, portioning, packing and palletising, as well as for handling unpackaged products or containers of frozen food. When handling soft or fragile food, the robots demonstrate sensitivity: they grip the products carefully and gently. Even when working at high speeds, they ensure consistent product quality.

Hygienic design and washdown capability

A key feature of Stäubli's food-grade robots is the hygienic design, which minimises the risk of contamination and helps to ensure maximum safety in this sensitive area of application. The design features include a Fully encapsulated and internally pressurised housing in protection class IP65 (wrist in IP67) with a smooth surface and special coating, internally routed cables and connections and the absence of dead spaces in which microorganisms could multiply. All models are available with food-grade NSF H1 oil.

Equally important is the robot's ability, the same cleaning procedures as the other system components to run through. Stäubli has developed the „Humid Environment“ (HE) robots for this purpose. They are modified in such a way that process reliability is guaranteed even when exposed to spray water and intensive daily cleaning.

Stäubli HE robots have established themselves as the benchmark for safe food processing. Because highly stressed parts are made of stainless steel, the use of materials such as plastic or carbon fibre can be dispensed with. The housing is coated with a special detergent and corrosion-resistant coating that has a particle-repellent effect. HE robots are available in different sizes, designs (four- and six-axis) and payloads to meet different requirements. Flexible mounting options enable easy integration into semi-automatic and fully automatic production lines.

Robots „live“ in action at the trade fair

At Anuga FoodTec, Stäubli will be giving several live demonstrations of how the hygiene-compliant robots can automate a wide range of processes in food production. This also includes the Safe handling of unpackaged food, including raw meat and baked goods.

In one of the demo cells, two Stäubli robots - the Red Dot Award-winning TS2-60 he and a TX2-60 he - will be shown cutting and handling chicken and beef using conveyor tracking technology. Another Red Dot Award winner, the SCARA robot TS2-80 he, will be seen at work in a bakery demo cell. This cell is also with conveyor tracking and equipped with a SICK 3D camera. The robot handles bagels at high speed, which it picks up precisely with a soft gripper and pushes into an oven. The VALtrack software from Stäubli enables the robot to process the camera data and handle different product types with a high degree of flexibility.

Six-axle vehicle modified for food production

Last year, Stäubli presented the new generation of the TX2-200: a powerful, cleanroom-compatible six-axis robot. The new HE version of the TX2-200 will be on display at the trade fair. With a load capacity of up to 170 kg and a reach of 2,209 mm the TX2-200 he is the largest robot in the TX2 series and the ideal solution for the Precise handling of heavy loads. Thanks to its dynamics, it achieves very short cycle times.

Another feature of the TX2-200 is the improved safety package. Thanks to the new safety functions, the robot can can be used at different levels of human-machine collaboration can. In practice, this means that its work area does not need to be enclosed by a safety fence, allowing the user to realise highly efficient collaborative production concepts.

Source: Stäubli

Stäubli at Anuga FoodTec: Hall 7.1, Stand C049