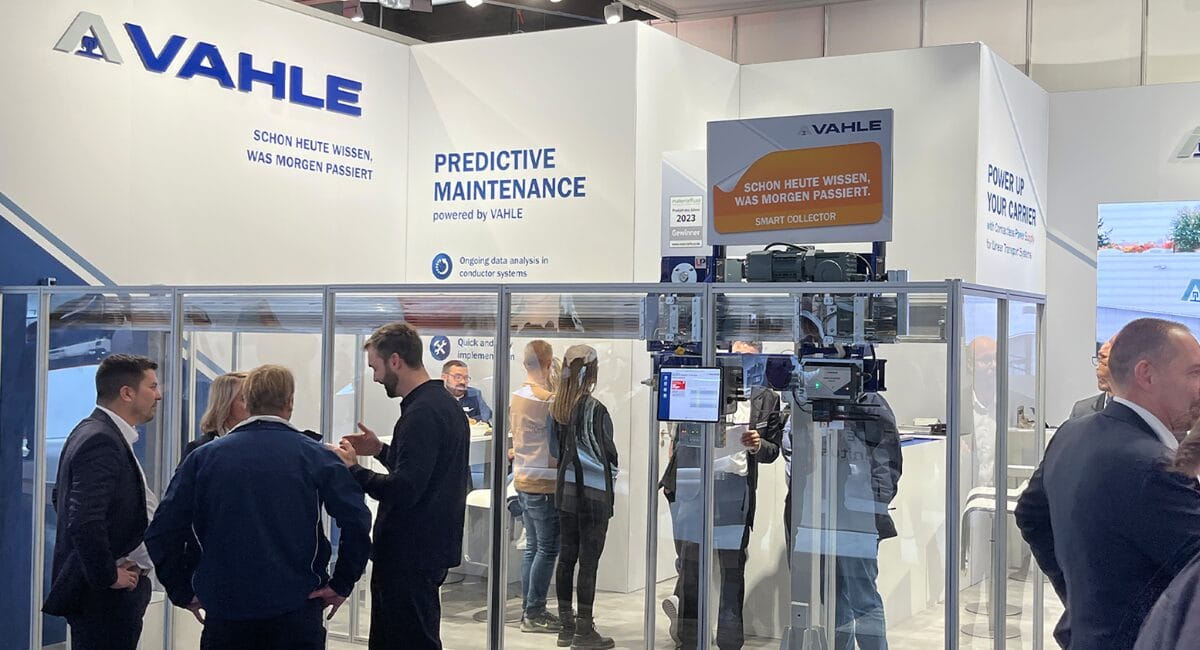

In Stuttgart, Paul Vahle GmbH will be showcasing solutions for predictive maintenance. These include an intelligent current collector system and solutions for energy transmission and process automation.

„The highlight at our trade fair stand is the Smart Collector, which new standards in terms of system availability and productivity and thus represents a pioneering solution for intralogistics. With its ability to detect errors and anomalies at an early stage, it enables worry-free and more efficient organisation of the supply chain process.“

Achim Dries, Managing Director of Vahle Group

The unique predictive maintenance tool for conductor rail systems is on display as a fully functional exhibit, including the latest developments. For example, by extending the phase spacing, the Smart Collector can now be used not only in logistics processes with a phase spacing of 14 mm, but also in systems with a spacing of 18 mm or 26 mm. This upgrade opens up a wide range of possible applications in various areas of intralogistics, including skid systems, automated storage systems, pallet floor conveyors, conveyor systems and sorting applications. „In addition, the integration of a new thermocouple sensor significantly to improve process reliability which in turn leads to increased system availability,“ emphasises Dries. This sensor is already being used successfully in several plants and has protected the system there from serious faults. The analysis option is also a useful addition to the existing motion data sensors.

The Smart Collector also plays a decisive role in the Avoidance of unplanned system downtimes and makes a significant contribution to making the supply chain process more efficient in the long term. Dries: „Our goal is to Increase the efficiency of intralogistics processes and to offer our customers innovative solutions for secure and reliable energy and data transmission.“

„We offer the optimum solutions for power supply and secure data communication for the wide range of applications in intralogistics. We take into account the different needs and requirements of our customers - whether through the use of inductive, wear-free technology or classic conductive Vahle components, such as our tried-and-tested U20 conductor rail.“

Achim Dries

Source: Vahle

Vahle at LogiMAT: Hall 1, Stand C31