Polybags - flabby mail items with flexible packaging are a challenge for automated sorting. An institute at Graz University of Technology has tackled this problem and created a widely applicable solution using a modern simulation method.

Anyone who orders something online would like to have the parcel delivered reliably, quickly and intact. The sharp rise in the number of so-called „polybags“ in recent years - mail items with flexible packaging and limited dimensional stability - has made it increasingly difficult for logistics service providers to offer this service. In contrast to rigid cardboard parcels polybags change their shape during transport and thus interfere with reliable automatic sorting. This problem has been addressed by the Institute of Technical Logistics at the TU Graz, Austrian Post and the company Körber in the ISAAK project funded by the Austrian Research Promotion Agency (FFG). Using realistic physical simulations, they have developed a solution that can also be used outside of mailings.

„The number of polybags has risen sharply in recent years, particularly for shipments from the Far East, due to the lower costs. To cope with the large volumes, logistics companies are sorting the shipments automatically, and with the method we have developed, this can now be done more reliably with polybags than before. As far as we know, we are currently the only company in the world to have tackled this issue.“

Christian Landschützer, Project Manager Institute of Technical Logistics at TU Graz

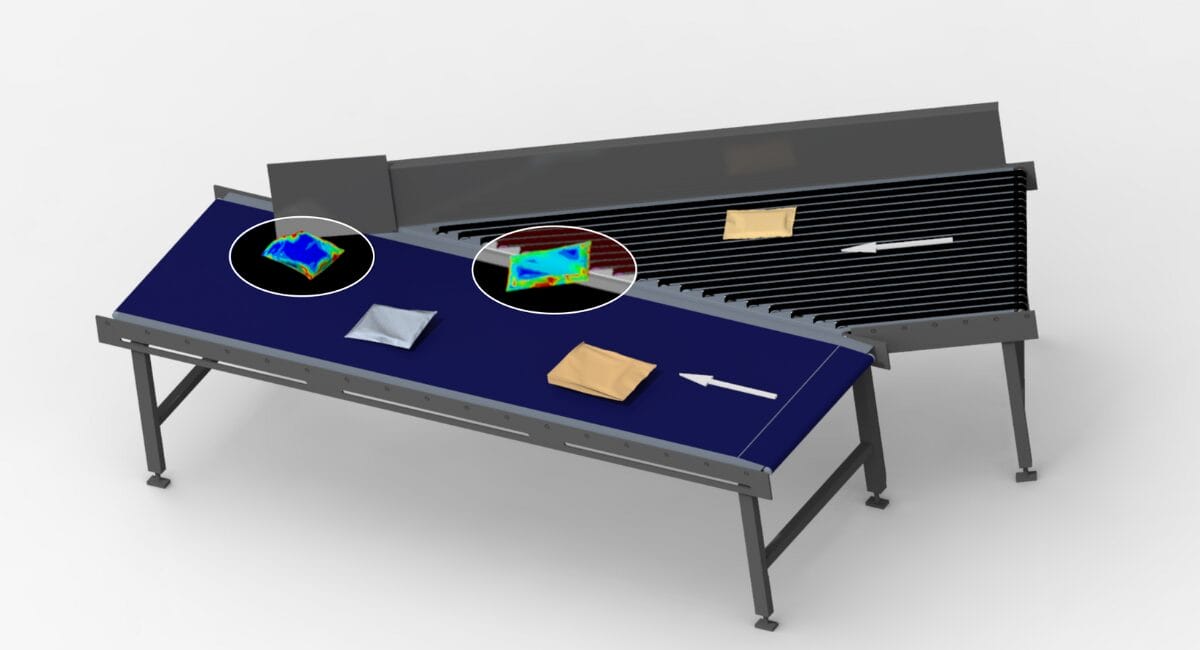

With the method in which the Simulate the behaviour of a polybag with physical precision a shipment can now be virtually tracked, recognised, physically described and sorted much more easily on its journey through a logistics centre. The practical thing about the solution is that it Can be used for numerous other mouldable containers with loose contents in the form of bulk or piece goods is. And it is also fit for the future, as it can be used to simulate future changes in packaging materials.

Analysing shipments

To develop the realistic simulation, it was first necessary to find out what types of mail are travelling. To do this, the researchers had to measure numerous consignments and describe their characteristics - and they were able to do this while a parcel centre was in operation, as they were of course unable to take the parcels with them for examination. The research team grouped the different parcel types into classes - known as clusters - and set about recreating these classes.

Tests were carried out with the replicas at Körber's test facility on Lake Constance. The test results provided the data for calibrating the parameters of the simulation model. This was created using modern multi-body dynamic and mechanical-physical simulation methods that can accurately reproduce the real behaviour of a consignment. Of particular interest are the resulting analysable forces acting on the shipments. Logistics experts can now use the clusters and their realistic simulation to optimise the improve the recognition and processing of consignments in their sorting systems. Producers of conveyor technology, such as project partner Körber, utilise the findings for the new and further development of systems within a virtual environment.

„Although the problem of mouldable packaging comes from the postal sector, it was important for us to look at the topic from the perspective of basic research in order to find a solution for several areas of application. This means that a wide range of sectors can benefit from our results.“

Christian Landschützer

The Institute of Technical Logistics would now like to utilise the research results of the ISAAK project for a follow-up project, which is already in preparation. Instead of just one Several polybags and their interaction simulated to further improve the description of consignments in the sorting process.

Source: TU Graz