Netstal demonstrates what sustainable and recyclable thin-wall packaging can look like and produces a thin-wall cup made of 100 per cent PET on a hybrid injection moulding machine. The clear cup has been optimised so that it can be recycled together with PET bottles to produce high-quality recyclates.

The recycling rate for thin-walled plastic packaging, such as cups for dairy products or spreads, is still low worldwide. PET bottles, on the other hand, play a pioneering role in recycling. Across Europe, half of all PET bottles placed on the market were recycled in 2020. The trend is also rising worldwide. Looking at all PET packaging, the rate is 35 per cent (source: Statista). Due to its good recyclability and the established recycling systems in several countries, the idea is obvious, Use PET for thin-walled packaging and make it recyclable. PET packaging must fulfil certain criteria so that it can be collected via the established collection systems and processed together with PET bottles into rPET regranulate.

„Clear packaging or the absence of colour additives is preferred in order to achieve the purest possible quality of the rPET. The recyclate obtained in this way can then be processed into new bottles or packaging.“

Reto Gmür, Product Manager Packaging at Netstal

Sustainable thin-wall cup produced in a climate-friendly way

Netstal and its system partners are demonstrating such a recycling-optimised solution as part of an exhibition project at the NPE plastics trade fair in Orlando/USA. The clear cup weighs around 15 g and has a filling volume of 450 ml. Netstal processes virgin PET from the Eastman Chemical Company. The cups are produced via the NPE recycling programme back into the PET cycle. The labels are also made of PET and are provided by the Belgian IML specialist Verstraete. The test mould with two cavities and the IML robot, which inserts the label into the cavity and removes and stacks the finished cups, come from Canadian partner StackTeck.

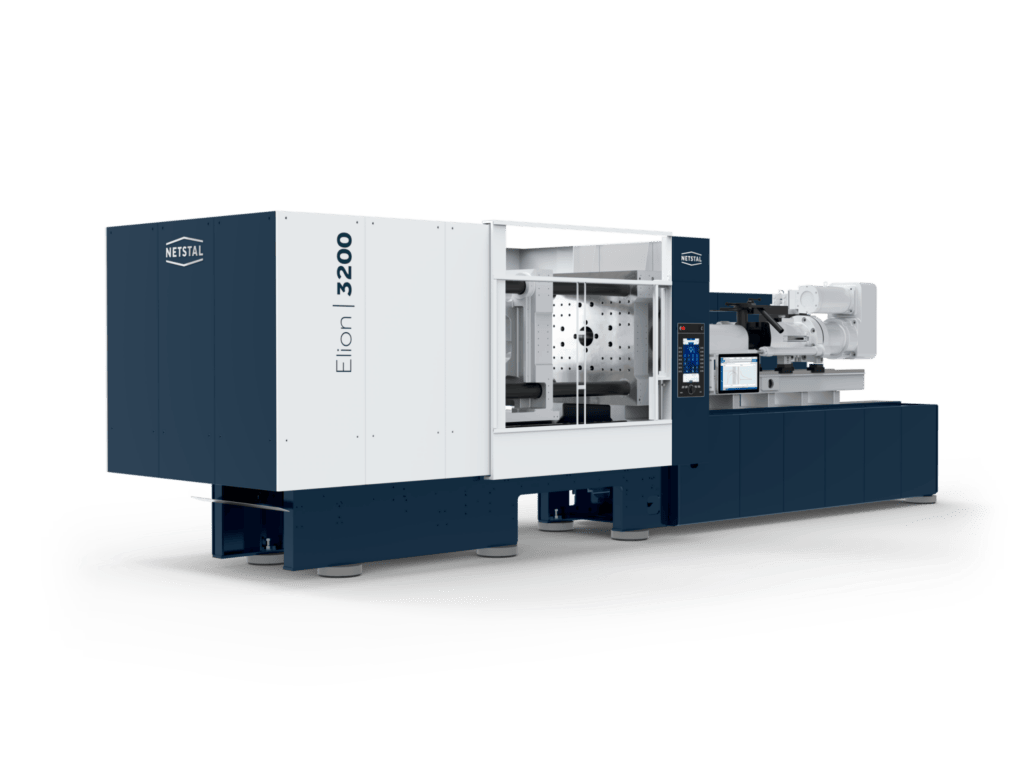

The PET cup is moulded in a cycle time of around four seconds on an Elion 3200, which provides the necessary speed, performance and dynamics with its electric toggle clamping unit and hybrid injection unit. With the recuperation of kinetic energy from the clamping unit the Elion is one of the most energy-efficient injection moulding machines in a market comparison. In high-speed applications, the Elion consistently operates in efficiency classes 8 and higher of the latest Euromap 60.1 standard. The unit with RFC injection control shines with its leading shot-to-shot consistency.

This is only available from Netstal in this form: The force-dependent pressure changeover takes place independently of the material properties and enables a constant part weight within the tightest tolerances. Thanks to the adaptive pressure reduction, the hydraulic system pressure is permanently regulated at the optimum point. Reto Gmür explains: „This option offers the customer enormous advantages. With a lower pressure, we put less strain on the axles of the machine. So availability is getting even better, and the machine consumes less energy. At the end of the day, Netstal users produce particularly efficiently and at the lowest unit cost.“

Source: Netstal