Poly-clip System offers the TSCA 120 automatic sealing and clipping machine for sealing snack packs for sausages and small portions. A specially developed film solution also produces a PVCD-free packaging system with a tear-open aid.

Food producers are adapting their product portfolio and packaging to the trend towards high-quality snacks with natural ingredients. Packaging should offer consumers as much convenience as possible. For the production of snack packaging solutions for sausage products and other small portions, the TSCA 120 automatic sealing and clipping machine from Poly-clip system a suitable solution. In contrast to conventional packaging for sausage snacks, the clip packaging (clip-pak) can be made from PVCD-free materials and demonstrates maximum performance.

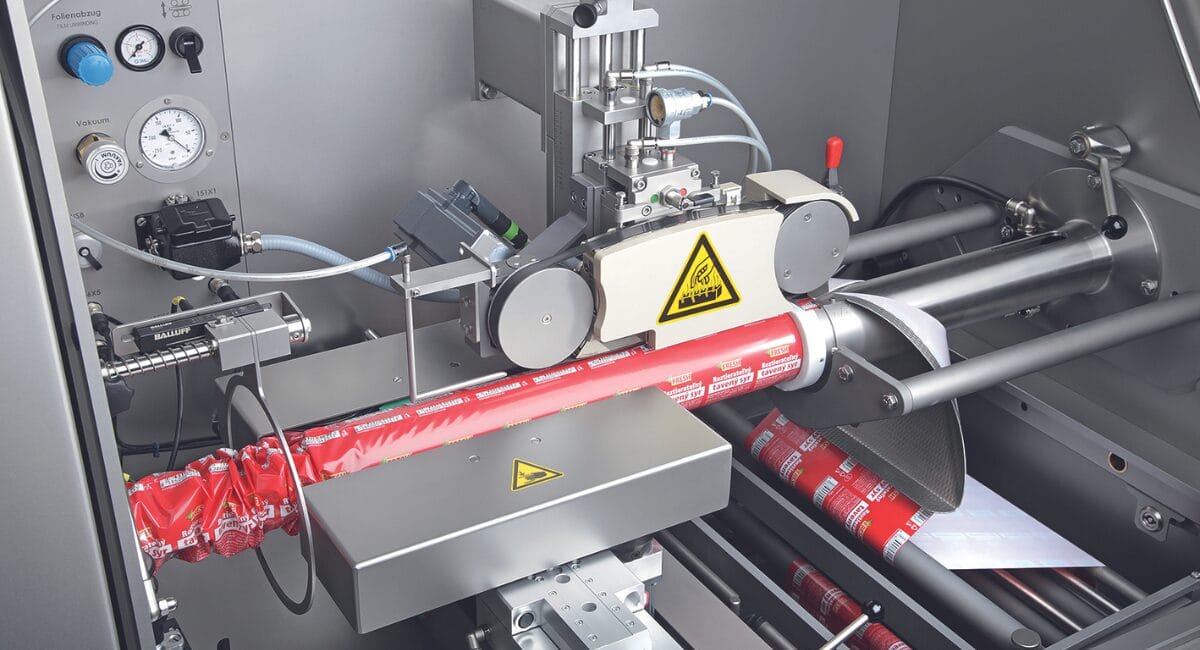

The TSCA 120 automatic sealing and clipping machine reliably seals a flat film to form a fillable tube and then seals it. Sealing the filled packaging with bacteria-proof R-ID clips. The machine uses an innovative film solution to produce highly cost-effective packaging with a tear-open aid, e.g. suitable for sausage snacks. It processes up to 3,300 metres of flat film at a time and thus achieves a running time of up to 4 hours without the need for operator intervention. The clip and film consumption is monitored automatically. For the highest Recipe management ensures process reliability, in which all parameters are stored. The robust machine is also characterised by its exceptional reliability: It has a consumption-orientated central lubrication system that reduces wear. This leads to Less maintenance and downtime and to an overall longer service life of the machine.

A modern snack pack with an innovative easy-opening solution can be produced with the high-performance TSCA 120 automatic sealing and clipping machine and the matching film. Heat-sealable composite films consisting of a PE (polyethylene) outer layer and a PA (polyamide) inner layer are used. The Opening concept based on defined lateral cut-outs in the flat film. It is prepared during the production of the flat film. In addition, the pre-defined opening is coated with an anti-sealing lacquer to create a tear tab during further processing. The TSCA 120 automatic sealing and clipping machine processes the flat film into a tube, which is closed with a longitudinal seam by heat sealing. During this process, the integrated flap does not bond with the film underneath due to the anti-sealing lacquer and prepares the opening aid. After filling, the tube is sealed in the integrated clip unit using the double-clip method with bacteria-proof R-ID clips securely sealed. To consume the snack, the packaging can later be easily pulled open over the sealed seam using the opening aid.

„With this innovative packaging for the growing snack segment, we are offering our customers an attractive and eye-catching solution that fulfils all the requirements of modern convenience packaging and eliminates the need for PVDC-based materials with controversial effects on health and the environment.“

Björn Arndt, Head of Viscopac / Head of Business Development at Poly-clip System

Source: Poly-clip System GmbH