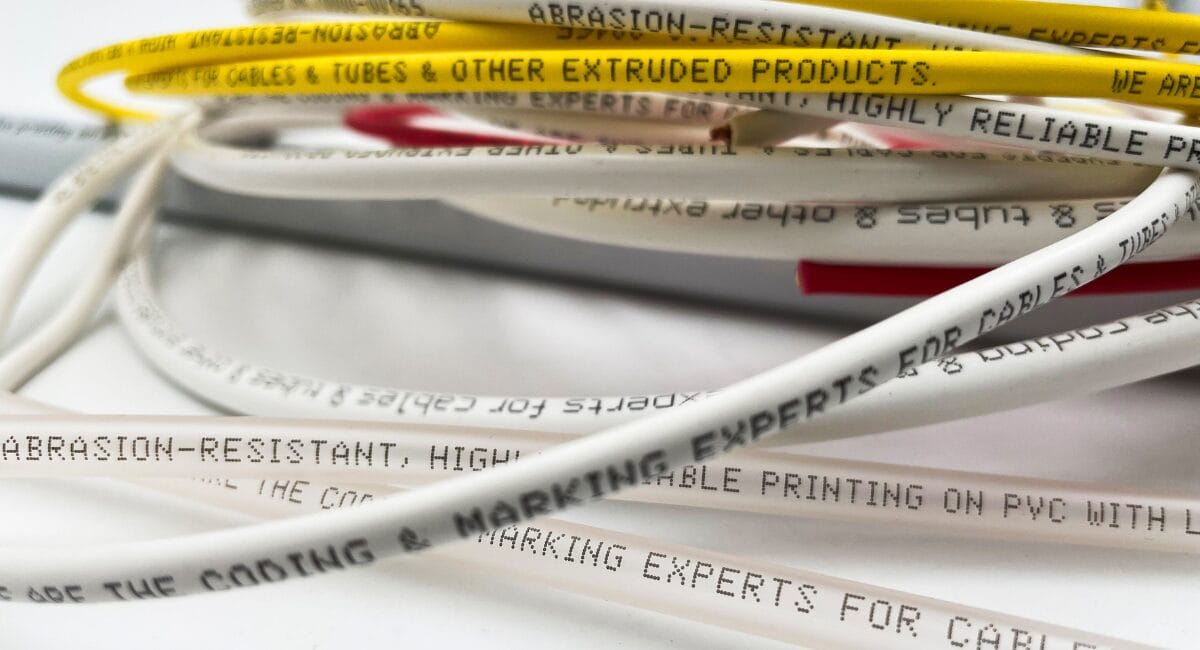

Pressure-resistant printing on strands, cables, metal cables or pipes and hoses made of soft PVC can be a challenge. Printer specialist Leibinger has developed an ink that is resistant to plasticisers and prevents imprints on neighbouring cables.

For reliable labelling of materials, two components should mesh like the gears of a well-oiled machine: Printer technology and printer ink. In contrast to various market competitors, the company develops and manufactures Leibinger therefore our own inks. These include a special black Ink for printing on extrusion products.

Extrusion products such as cables, sheathed cables, hoses, pipes or profiles consist to a large extent of polyvinyl chloride (PVC). Depending on the application, this is mixed with plasticisers, also known as „softeners“. After production, the printed cables are usually wound up. Due to the „plasticiser migration“, an imprint or „transfer print“ may appear on the adjacent cable when it is subsequently unwound. To prevent this, Leibinger has developed a special PVC ink.

The company has developed a special ink for cable labelling and metre marking of extruded goods that adheres securely to PVC materials. It is Resistant to plasticisers and thus prevents the above-mentioned effect of an undesirable imprint. With a BWS (Blue Wool Scale) ranking of 8, it also has excellent UV stability, which is particularly important when used on window spacers, for example. Furthermore the ink dries very quickly and is therefore also ideal for high-speed applications. The article number of the strong PVC ink is 70000-00165.

Source: Leibinger