After an eight-year break from drupa, Asahi Photoproducts is also delighted to be back in Düsseldorf at the end of May. The company will be showcasing its flexographic printing solutions and how the portfolio can save solvents and waste water.

Asahi Photoproducts will be showcasing its solutions for the printing industry at the Düsseldorf Exhibition Centre from 28 May to 7 June 2024. „Since Asahi Photoproducts was founded more than 50 years ago,“ says Dieter Niederstadt, Technical Marketing Manager at Asahi, „we have been developing sustainable printing materials, such as the liquid photopolymer resin APRTM, which is processed with water. Together with our parent company Asahi Kasei, we are pursuing the goal of bringing products to the market that contribute to improving people's quality of life and creating a pleasant working environment.“

„As the majority of flexographic printing plates are still processed using solvent-based washout processes,“ emphasises Dieter Niederstadt, „we will be showing trade visitors at our stand how easy it is to switch to Solvent Zero so that they can make their workflows more sustainable and offer their employees more pleasant working conditions. The first step is to focus on Printing plates with reduced solvent consumption, such as the AFPTM-R with CleanPrint technology from Asahi. This product requires 30 per cent less solvent, without the need for additional investment in the systems. The user only has to change the printing plates and is already a good step closer to the goal of solvent zero.“

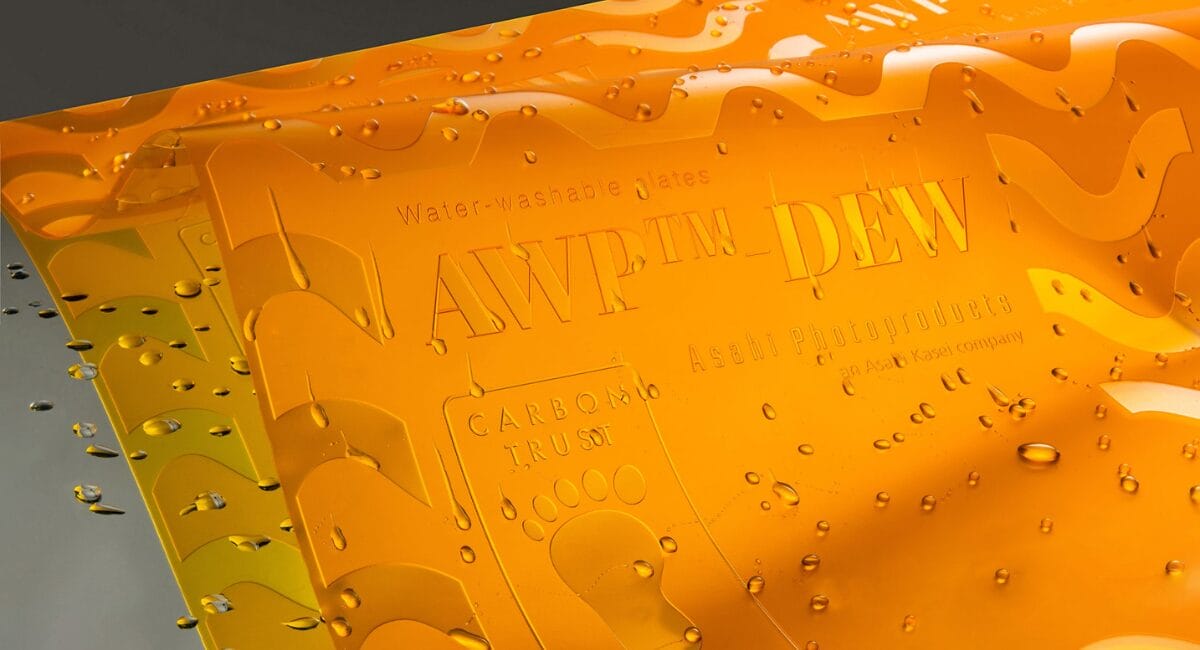

In line with Asahi's corporate philosophy, the company helps flexographic printing plate manufacturers to embark on the path to Solvent Zero, while at the same time protecting the Reduce water and energy consumption and improve productivity and quality on the printing press. The AWPTM-DEW and AWPTM-CleanFlat water-washable printing plates have already received carbon neutrality certification in cooperation with The Carbon Trust. Visitors can also find out how the AWP-LOOPTM water recycling system can save up to Saving 85 per cent of wastewater leaves.

At drupa 2024, Asahi will present its full range of flexographic printing plates as well as new plates developed for printing on paper, corrugated board or even recycled film. Due to their high register stability from inking unit to inking unit on the printing press, the plates are ideal for printing on paper, corrugated board or recycled film. Printing in extended colour gamut (ECG) to achieve both print quality and better sustainability.

At drupa 2024, the company will present trade visitors with CrystalCleanConnect, the latest development in the production of flexographic printing plates to the market. This automated system, developed in collaboration with ESKO and Kongsberg, has already been installed at several locations worldwide. It reduces the number of production steps from 12 to 1, reduces the amount of labour required and the likelihood of errors and provides a ready-to-install printing plate. In addition, Asahi offers a digital technical support service of the customer's choice with smart glass technology or via smartphone.

Source: Asahi Photoproducts

Asahi Photoproducts at drupa: Hall 8b, Stand A13