REA Elektronik, the specialist for packaging and direct product printing, will be showcasing innovations from its Industry 4.0-capable portfolio at Fachpack 2024 in September, including the new, high-resolution, environmentally friendly multi-talent REA JET UP for direct carton printing.

The REA JET UP is a completely newly developed direct printing system based on piezo technology. UP stands for „Universal Print“ - and is a Alternative to the glued label. While most systems can only print high-resolution content on absorbent surfaces such as paper, cardboard and wood, the REA JET UP can also do this on smooth and refined surfaces. And with a high drying speed, thanks to its patented, fast-drying special inks.

With a print height of 108.4 mm, maximum print resolution of 360 dpi (vertical) and 1,500 dpi (horizontal), a tripling of the previously known speed potential and an ideal print distance of 3 mm, the REA JET UP especially for carton labelling an interesting system.

Modern control system, label printing and code checking

Also on show at Fachpack 2024: the TITAN Touch Controller. It works without buttons or knobs and is controlled exclusively by touching the easy-to-read 10.1-inch display and the modern, tile-based user interface - even when wearing gloves.

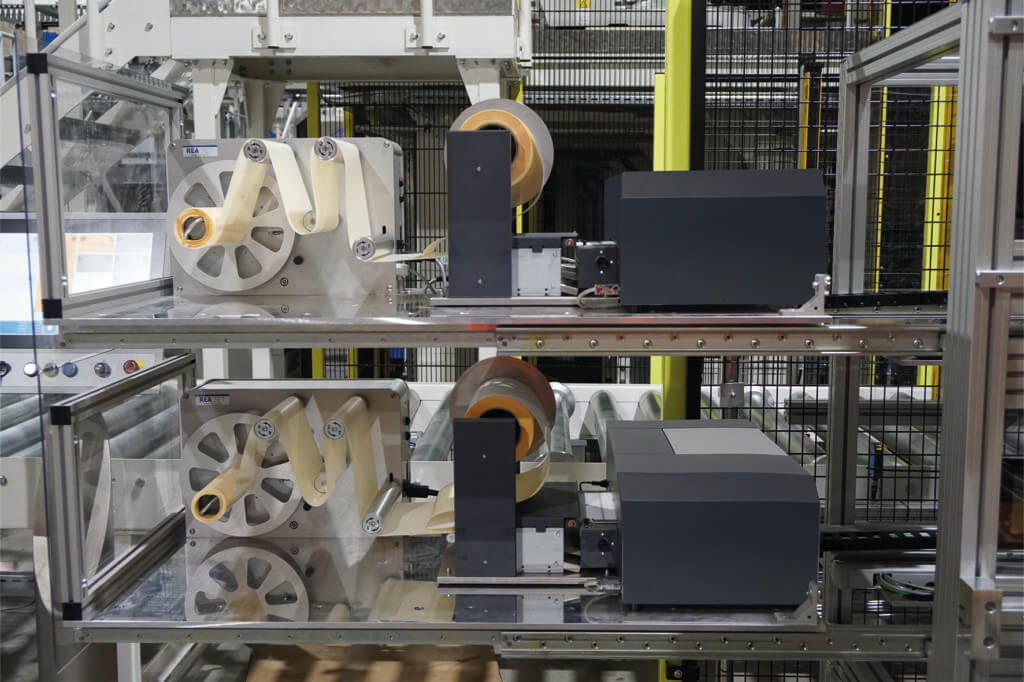

As a compact colour label printer, the new REA LABEL ColorJet 2 is a cost-effective alternative for small and medium print volumes. With its compact design and robust, powder-coated housing, it is the right choice for industrial use in production, logistics, automation and everywhere else where high-quality colour labels need to be available „on demand“. In addition, the majority of its individually replaceable components are made of recyclable material.

The REA LABEL ColorJet 2 comes in three versions and prints small and medium quantities of labels individually or in series full-colour with a print width of up to 210 mm and in the highest resolution of up to 1,200 dpi. Users can choose between dye ink, pigmented or nanopigmented ink for the label material. from matt paper to high-gloss PET film - in coordination with the selected ink type. The printer only needs to be set up to a limited extent, as the labels are fed in automatically and their dimensions are read and displayed.

With the standard REA LABEL ColorJet 2S model, the label can be removed manually using a tear-off edge, while the REA LABEL ColorJet 2C with circular blade cuts labels individually or after a print job. The REA LABEL ColorJet 2P offers a unique selling point: it can print and dispense labels 1 to 1 in full colour. The backing paper is wound up by an external rewinder. This system can be used, for example, for manual workstations or fully automated applications in applicator mode or robot systems. It has a flexible PLC I/O interface.

And finally: the REA VeriMax. The modern Matrix and barcode tester is specially designed for fully integrated installation in production lines and, thanks to its compact dimensions, fits into any system. Its two operating modes enable both manual random sample inspection and inline inspection, with which up to five complex codes per second can be reliably verified in accordance with ISO standards. The REA VeriMax is also suitable for GS1 Digital Link structure checks and for the upcoming codes for „2D in Retail“, codes with batch and date information for reading at the checkout.

Source: REA Electronics

REA Elektronik at Fachpack 2024: Hall 1, Stand 1-223