At Fachpack, Trapo is presenting the new compact class of its robot palletisers with three basic models. All palletisers in the series are also available in a food-compliant version and are then FDA-approved.

The robots can be integrated into all existing spaces and are ideal for production halls with existing ceilings of 2.60 metres in height. The robust, space-saving compact class is starting the new trade fair season with three sophisticated models.

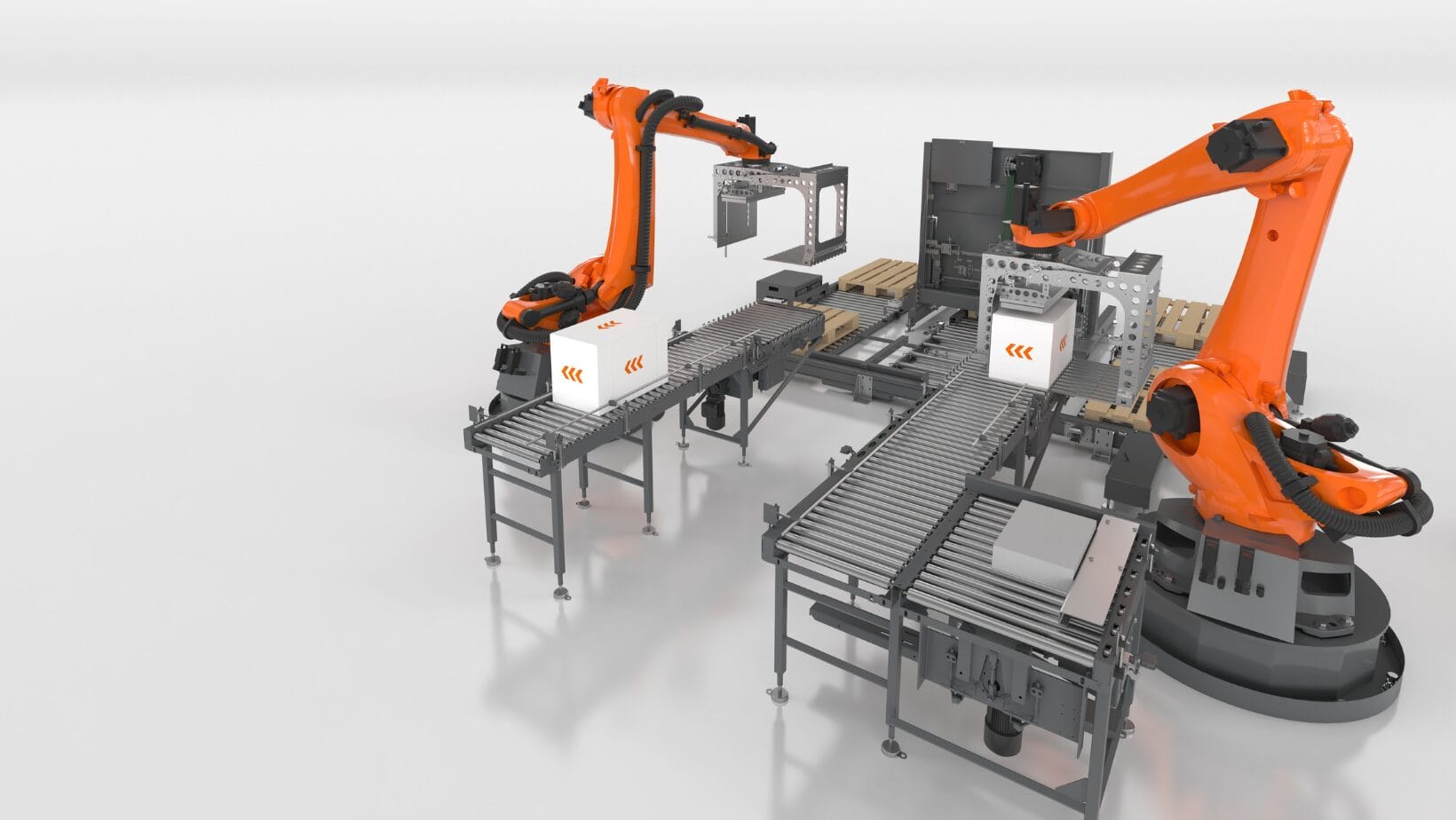

For end-of-line palletisers, which are used at the end of a production or packaging line, Trapo Articulated robots from the High-Speed Robot System series (HRS Series) plus multifunctional gripper on. The compact class of robotic palletisers is designed to optimise production processes as well as product handling and productivity. Thanks to a modular system, there are numerous options for meeting individual automation requirements.

The compact class offers three basic models Solutions for palletised goods such as buckets, bags, barrels, cans, cartons, canisters and more. As an experienced partner, Trapo complements the palletising line with AMR expertise, pallet buffer systems (sequencers) and automated truck loading with the TLS 3600 loading system, for example. The company specialises in the needs of the food and pet food industry.

Small robot for big relief: The Trapo Cobot Palletizer (TCP) fits through any door - the performance model for easy entry into automated palletising. Delivered on just two pallets, the mobile robot is mobile, who can act as a „colleague“ without a fence, The Cobot can be used wherever its palletising performance is required. At the same time, Trapo is providing a convincing answer to the shortage of skilled labour with the Cobot: employees who previously palletised manually can now be deployed elsewhere in production.

End-of-line palletising - integrated into reliable conveyor technology

The entire process is supported by a reliable roller conveyor. This not only ensures Smooth feeding of the products, but also for the orderly provision of pallets. As an option, the palletisers can be supplied with empty pallets via a robust empty pallet magazine to stabilise the workflow. All robots in the compact class deliver the pallets via conveyor technology at floor level - from there they can be removed manually using all standard pallet trucks.

The flexibility of the compact class is the optional layer pad handling extended. This can be done either as an integrated additional function on the robot's gripper or via a separate swivel arm, which handles the layer pads separately from the actual palletising process. This additional sheet feeder further increases the performance of the palletising process.

Palletising software for freely selectable stacking patterns

Companies in the packaging industry are taking a further step towards automation with the Trapo Pack software. This efficient, easy-to-use palletising software configures the optimum layer pattern from the dimensions of the package and the pallet - for perfect stack formation as the basis for stable shipping units. Once generated, layer patterns are optimised on the monitor. Layer patterns and pallet loads can be configured by the user and saved for subsequent palletising processes.

Source: Trapo

Trapo at Fachpack 2024: Hall 3C, Stand 551