PlastiVation Machinery GmbH is using Fakuma 2024 to present two models from the latest generation of its Tederic NEO series of electric injection moulding machines. The NEO-E160/e620, which produces a cup holder with three cups as part of an automated production cell, will take centre stage at the trade fair. Another exhibit, the NEO-E60/e110, will demonstrate the production of a prototype part using a 3D-printed mould. The company will also be providing comprehensive information on its service packages and digital solutions for increasing efficiency.

PlastiVation is optimistic with regard to the coming days of the Fakuma 2024 and will present two electric injection moulding machines from the second generation of the Tederic NEO series this year. Thomas Strecker, Managing Director of PlastiVation Machinery GmbH, emphasises the Energy efficiency and technical sophistication of the machines, which are intended to be an attractive investment solution as part of automated production cells.

The Tederic NEO series comprises four models that can be operated electrically, fully electrically or hydraulically and offer clamping forces of up to 7,000 tonnes. Strecker explains that the Technology upgrade of the second machine generation meets with a positive response from plastics processors had been achieved. These are said to have been brought up to the level of European injection moulding machines thanks to technological improvements, which has supported a pleasing order trend in the DACH and Benelux sales regions.

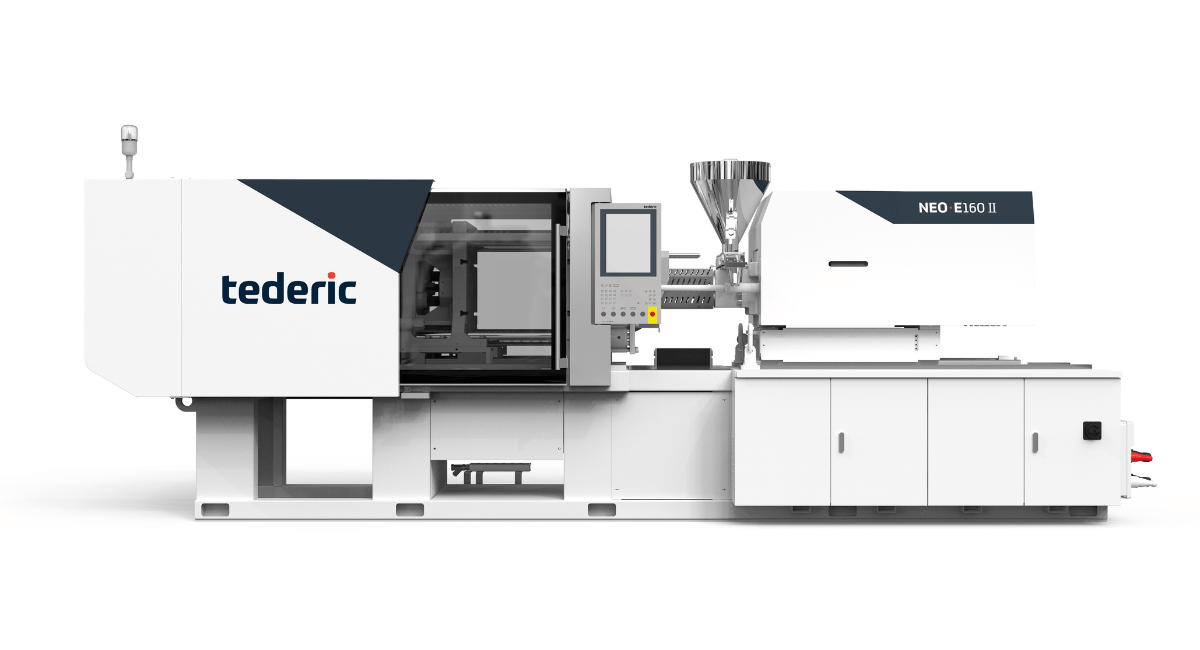

Cup holder with three cups

The NEO-E160/e620, which will be presented at Fakuma 2024, is characterised by a clamping force of 160 tonnes and a screw diameter of 42 mm. It produces a cup holder with three cups made of PC-ASA material. The shot weight is around 150 grams, whereby the Cycle time 42 seconds is. The finished cup holder weighs 74 grams, while a single cup weighs 23 grams. The machine is equipped with a KEBA control system and a 15-inch screen.

Production takes place in a automated and CE-compliant production cell, which is equipped with a Sepro robot. A 3+1 hot runner family mould from INCOE International Europe, equipped with a pneumatic 4-way valve gate system and the Heat-Inject dynamic mould temperature control system, is used. This technology enables the production of Cup holder with openings for the cups, without binding seams become visible on the surface. This is achieved by introducing heat impulses into the mould wall, which increases the temperature at the critical points and thus prevents the typical notch formation.

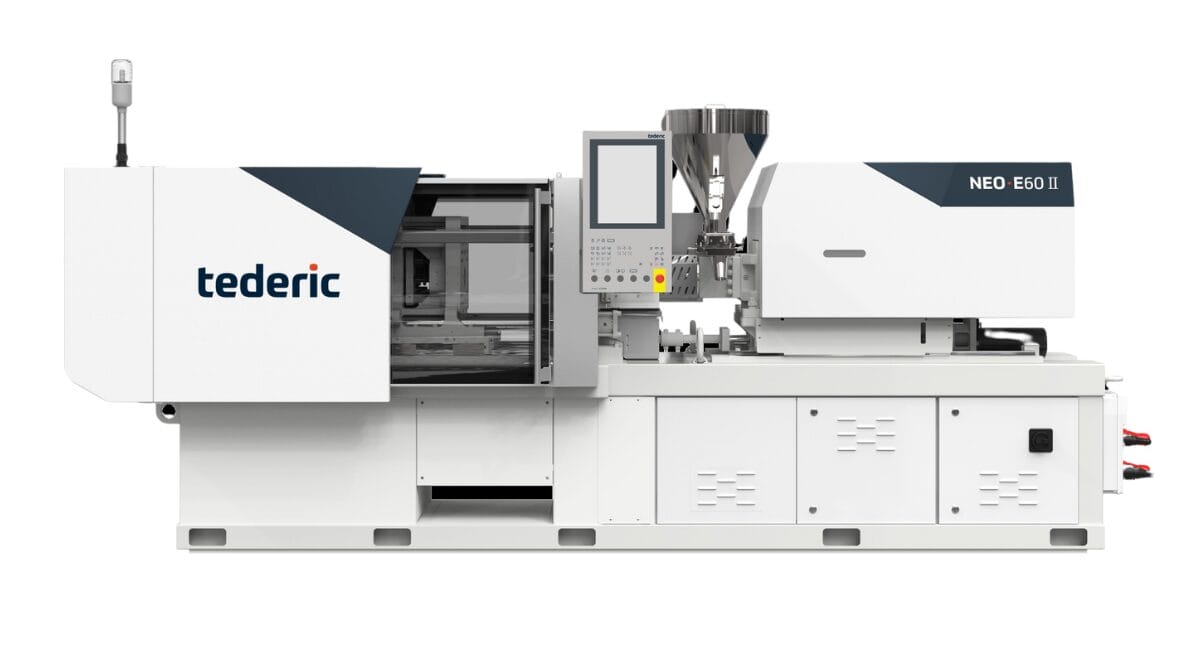

Prototype production with 3D-printed tools

Another highlight at Fakuma is the NEO-E60/e110, which demonstrates prototype production with a tool mould produced using the 3D printing process. This mould, which can be used multiple times, produces a Prototype part made of polypropylene. The partner in this project is SK Industriemodell GmbH, which has developed the ‚Print & Inject‘ process. This process makes it possible to produce extremely complex or intricate components and prototypes in research and development as well as in prototype construction without having to rely on conventional moulds.

The use of xMould high-performance resins in this process is intended to make the production of moulds and complex components with undercuts more cost-effective. In addition the costs for warehousing and maintenance are eliminated of injection moulds. The NEO-E60 is also equipped with a KEBA control system and a 12-inch screen.

PlastiVation is also using Fakuma to present its four service packages to plastics processors, including the „Energy Care“ package, which aims to reduce energy costs. Visitors can also find out about digital solutions and the ServiceNet technical assistance system, which promise greater information transparency and production efficiency.

PlastiVation offers around 30 experienced service technicians at six locations in Germany, who are available for technical application advice and support with maintenance, repairs, installations and machine optimisation. These services are intended in particular to Preventive maintenance and fast response times in the event of problems.

Source: PlastiVation

PlastiVation at the Fakuma: Hall B3, Stand 3215