Syntegon is expanding its coffee packaging portfolio with the market launch of the PMX 4001 vertical form, fill and seal machine for ground coffee and whole beans. The space-saving machine processes both composite materials and recyclable mono-materials.

With the new PMX 4001, the company now offers manufacturers the usual product protection and high-quality packaging of the PMX series in a much smaller space. Visitors to Fachpack can experience the machine in the form of a 3D animation. Also on show: The VIS 10F coffee degassing valves made of monomaterial from Syntegon, recently launched by the Institute cyclos-HTP have been certified as recyclable throughout Europe.

„Many manufacturers do not yet or not yet fully fulfil the requirements of the European Union's Packaging & Packaging Waste Regulation (PPWR), which will come into force in 2030. They are now looking for solutions. At the same time, flavour protection and quality remain crucial, especially for coffee. With the PMX 4001, we are helping our customers to fulfil these requirements.“ Christina Holm, Product Manager at Syntegon

Sustainable partner for recyclable packaging

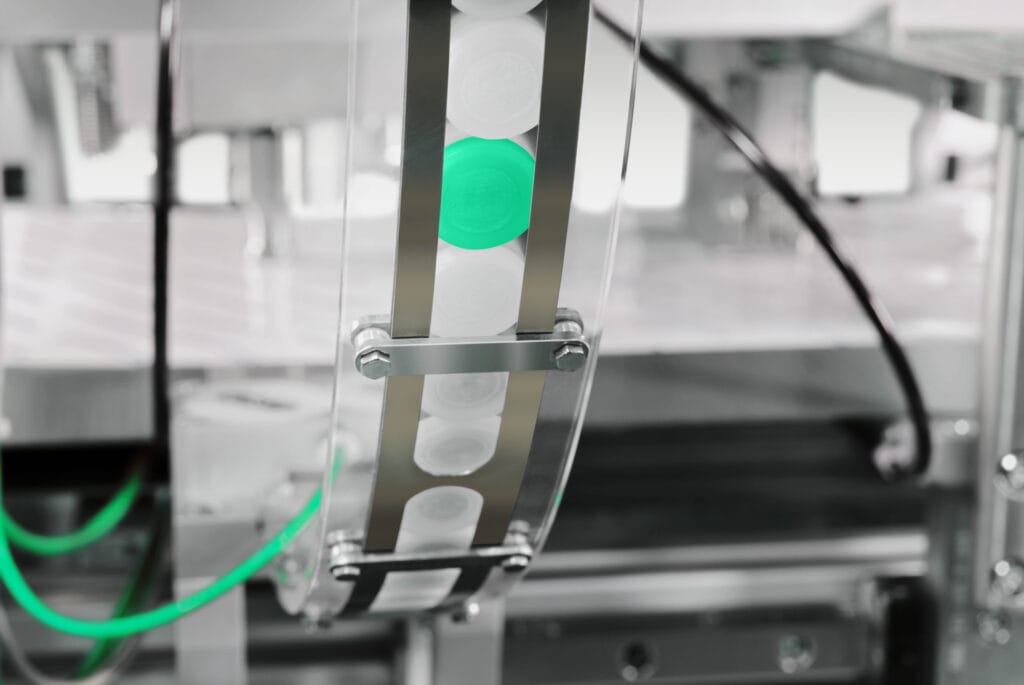

Sustainability was a key consideration in the development of the PMX 4001 right from the start: „We designed the PMX 4001 to be Alternative packaging materials for high output - up to 65 packs per minute with a pack weight of 500 grams,“ says Holm. This refers not only to the innovative sealing of the film from which the PMX 4001 forms stand-up pouches, but also to the gentle ultrasonic technology for the application of recyclable degassing valves.

The choice of more environmentally friendly packaging materials depends on many factors, such as the protection requirements of the product or the packaging machines. Syntegon therefore offers manufacturers sound support during the changeover in the form of packaging material advice, which covers both Analyses of material properties in our in-house laboratory as well as practical tests on the machine includes. Syntegon also supplies coffee manufacturers with flavour-protecting coffee degassing valves made of mono-material, which have been certified as „excellently recyclable“ in accordance with an EU-wide standard.

High-quality coffee packaging in the smallest space

The quality of the coffee bags is reflected not only in the material but also in the processing: the PMX 4001 is perfect thanks to gentle product handling, integrated valve application and gassing of the coffee to minimise residual oxygen customised for the packaging of coffee - and ensures flavour protection and a long shelf life. The appearance of the packaging also influences the purchasing decision, especially for a luxury product such as coffee. The machine takes this into account and achieves extremely precise sealed seams a high-quality product appearance. The PMX 4001 the most compact machine in the series and thanks to its low height and footprint of just 2.6 by 2.1 metres, it is also ideal for manufacturers with limited space.

Future-proof with condition monitoring and seamless solutions

Sustainability does not end with environmentally friendly materials - many manufacturers are also optimising their production processes to make them more resource-efficient and therefore more sustainable. To do this, companies need transparency about their production. The Industry 4.0 solution Synexio Empower installed as standard in the PMX 4001 monitors all machine functions as well as energy and resource consumption in real time.

Syntegon also offers manufacturers turnkey coffee packaging machines and systems that cover all stages of the packaging process. This also includes Solutions for secondary packaging of coffee, such as the Elematic case packers, which are available as wrap-around, side or top loaders, as well as advice and services.

Source: Syntegon

Syntegon at Fachpack 2024: Hall 1, Stand 257