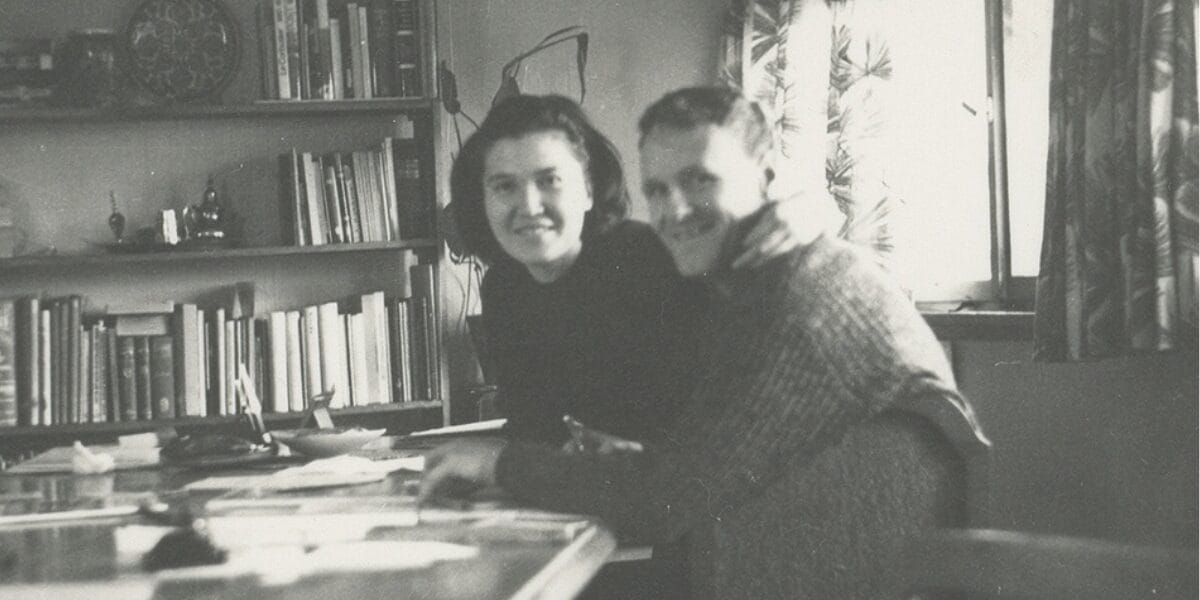

When self-service markets appeared in Germany in the early 1960s, Dr Karl Busch quickly recognised the potential of this new form of shopping. He developed the first vacuum pump specifically for packaging food. Shortly afterwards, he and his wife Ayhan founded their company, which quickly became the global market leader with its pioneering technologies and is now one of the largest suppliers in the vacuum industry worldwide.

Today's Busch Group, which was founded in 1963 as Dr.-Ing. Karl Busch GmbH in Schopfheim, Baden-Württemberg, in the border triangle of Germany, France and Switzerland, developed into a successful global player within a very short space of time. Their recipe for success: customised vacuum solutions for a wide range of industries and thinking outside the box at an early stage. From the very beginning, the founding couple thought far beyond the borders of Germany. As early as 1971, one year before the company moved to neighbouring Maulburg, the first foreign subsidiary was established in the UK. And as early as 1981, Busch became the first German industrial company to sign a co-operation agreement for production in China. In just 15 years, further 18 subsidiaries and four production sites was added. At the same time, the product portfolio grew and now includes solutions for Vacuum, overpressure and exhaust gas cleaning applications includes.

Products from Bush can be found in numerous sectors, from the semiconductor industry to wood processing, medical technology, the food industry, analytics and the chemical and plastics industries. In addition, Busch designs and builds Customised vacuum systems for its customers and offers them optimum support through its global service network.

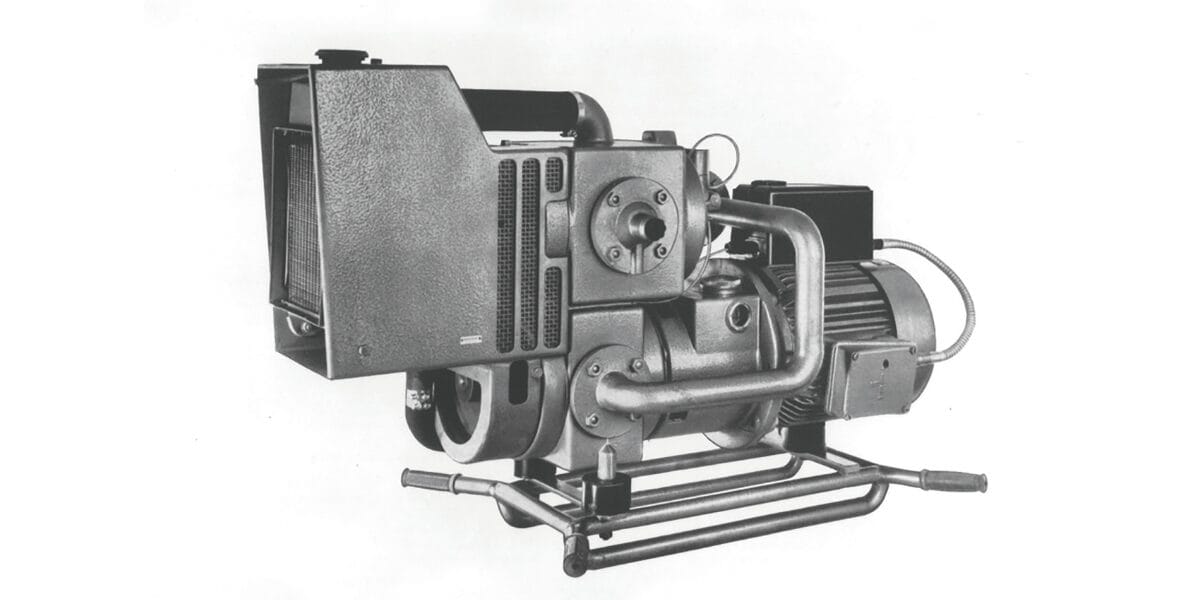

Initial ignition with the piggyback

It all started with the first vacuum pump specially designed for the requirements of the food packaging market, the Huckepack. Dr Karl Busch developed the Space-saving and robust oil-lubricated rotary vane vacuum pump At the beginning of the 1960s. It represented a milestone in food packaging. For example, it can be used to form plastic film into packaging trays and extract air from the packaging before sealing to protect the contents from drying out or early spoilage by bacteria and fungi. Thanks to its stacked pump stages, the robust Huckepack also requires very little space and therefore still fulfils the high requirements of the industry today.

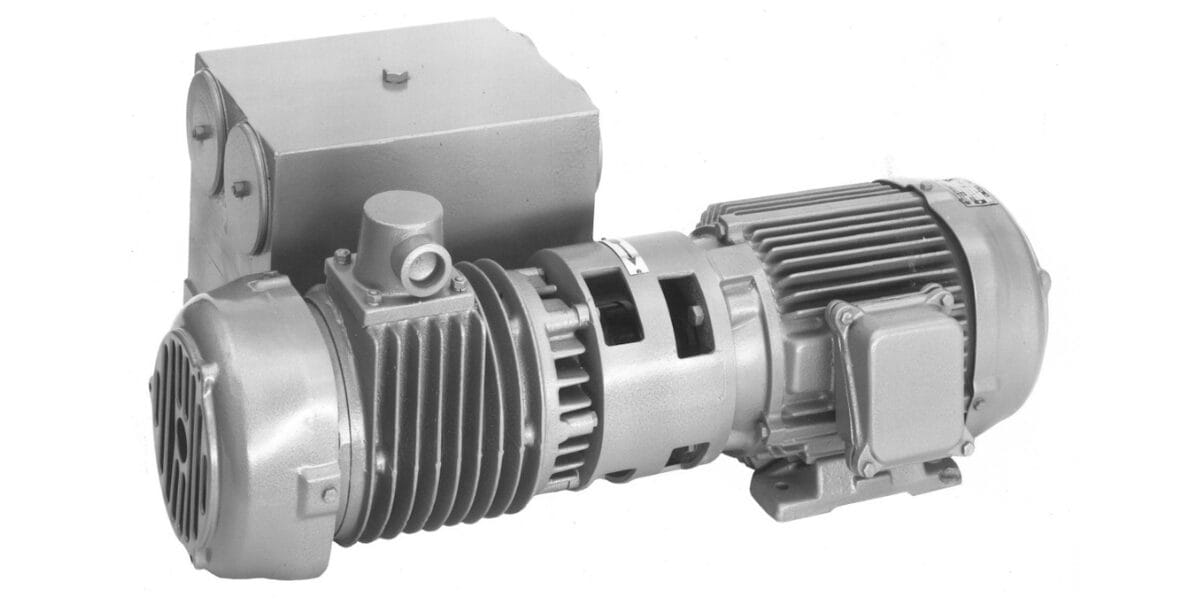

Industry standard in the packaging industry R5

The reliable R5 rotary vane vacuum pump is the successor to the trend-setting Huckepack. Since its introduction in 1969, it has established itself as the industry standard in the packaging industry. In the meantime Over three million R5 pumps in use worldwide: proof of the trust that customers all over the world place in the quality of Busch products.

The R5 is ideal for vacuum packaging food. It has been continuously developed and optimised over the years, not only in terms of energy consumption, in order to meet the increasing demands of the industry. It is also particularly low-maintenance and is characterised by great economy and efficiency. from. The R5 rotary vane vacuum pump is available in various sizes and performance classes for different applications. This enables flexible adaptation to the respective requirements of the packaging machines, whether in chamber packaging machines, thermoforming packaging machines, traysealers or bag filling machines. With a market share of over 85 per cent, the R5 has made Busch the World market leader in the vacuum packaging market segment.

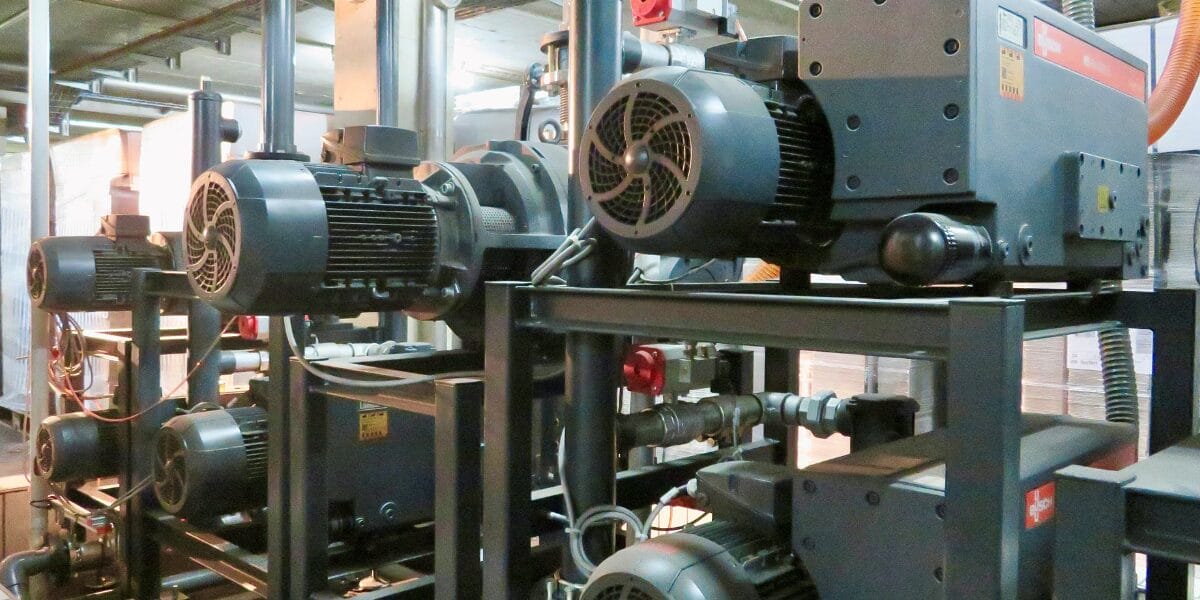

The pump is used, for example, at Südbayrische Fleischwaren GmbH, which supplies Edeka Südbayern with meat and sausage products. At its plant in Obertraubling, 22 to 24 tonnes of raw and cooked sausages are produced every day, which are packaged on four packaging lines with thermoforming machines. In order to centralise the vacuum supply, the experts from Busch designed a vacuum system with R5 rotary vane vacuum pumps and connected all four packaging lines to it. The Centralisation and demand-based control make the vacuum supply extremely economical.

Three strong brands

In 2023, Busch acquired Pfeiffer Vacuum, a long-established global company based in Hesse, which develops and produces high and ultra-high vacuum technology, including for the semiconductor industry and the analytics market, as well as leak detectors. In the same year, the global Busch Group was completed by centrotherm clean solutions, a leading manufacturer of exhaust gas purification systems for the semiconductor industry.

Today, worldwide More than 8,000 employees in 44 countries and 110 subsidiaries work for the Group, which has 19 production plants in China, Germany, France, the UK, India, Romania, Switzerland, South Korea, the Czech Republic, the USA and Vietnam and a consolidated annual turnover of almost two billion euros.

A family business through and through

The management of the group of companies is still in the hands of the Busch family. It is managed jointly by the company founders Ayhan and Dr Karl Busch and their three children Ayla, Sami and Kaya Busch, who make all important decisions together. For this company culture and co-operation, as well as for their Living diversity between generations, genders and cultures in 2022, the Busch family received the most prestigious honour for family businesses in Germany, the „Family Entrepreneur of the Year“ award.

The family concept is also an important part of the company philosophy, as cohesion is a top priority in this traditional company. Busch attaches great importance to long-term customer relationships and employment relationships. The high quality and the resource-saving durability of Busch products are core components of our corporate identity.

Committed to sustainability goals

The Busch Group also impresses with its enormous innovative strength: the company is involved in forward-looking solutions for a wide range of industries that set new standards. Busch products are needed for the production of biodiesel as well as for the production of wind turbines. With their help, carbon dioxide can be filtered out of the air. They are used in fuel cells that power vehicles with hydrogen instead of fossil fuels. They are used in Hyperloop test tracks, where research is being conducted into how faster train journeys could be possible in the future. They are used for the production of microchips. They are being used to research fundamental questions of physics at the European nuclear research centre CERN and are being used in the international ITER research project, which aims to develop a sustainable and secure energy supply for the future.

In demand in practice

At the Crailsheim-Dinkelsbühl dairy plant, a pressure-controlled vacuum system with R5 rotary vane vacuum pumps thermoforms the packaging, evacuates and seals it, erects large shipping cartons and inserts the cheese packaging. Thanks to the Busch vacuum system, the Productivity significantly increased and energy consumption reduced at the same time become.

(Image: Crailsheim-Dinkelsbühl dairy)

The diverse applications of its products and their great importance for many industrial processes make the Busch Group a company that is characterised by particular crisis resistance. This was also evident in the Corona pandemic, when Busch vacuum pumps were urgently needed in hospitals around the world have been. The first hospital that Busch equipped with the necessary vacuum supply at short notice was a hastily constructed emergency hospital in Wuhan, China.

Positioned for the future

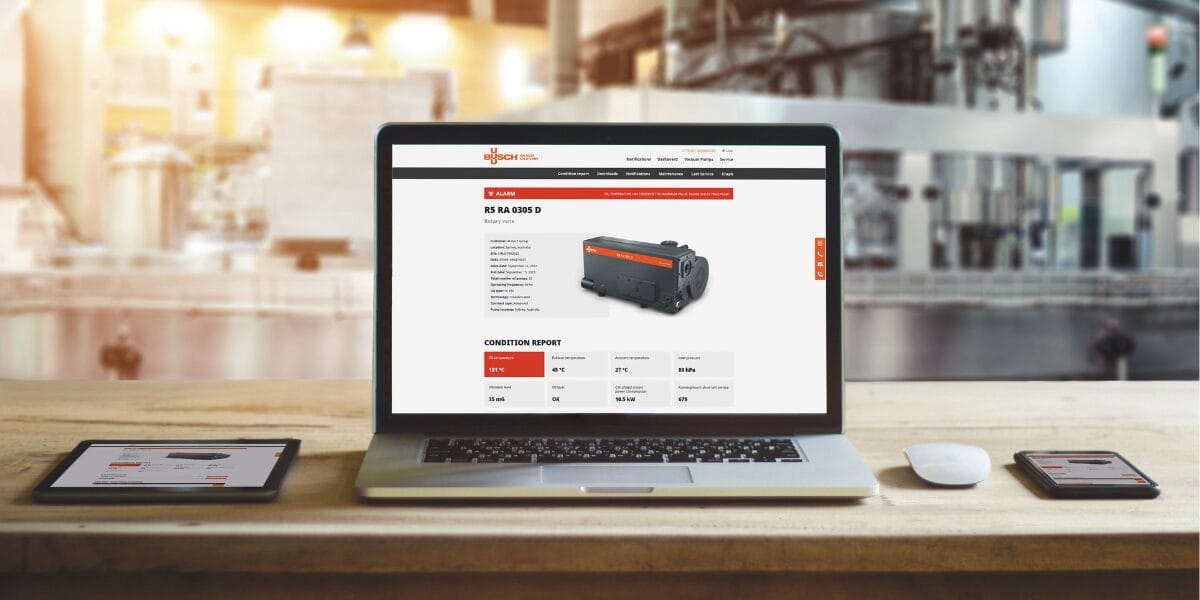

Production downtime is a major and expensive problem for factories. Intelligent IoT solutions can help to reduce production downtime. Busch has developed a digital service innovation with Otto. They combines the condition monitoring of vacuum pumps with attractive service packages - for high process reliability and lower operating costs in production. Otto Digital Services support Busch customers in remaining competitive in the future.

Despite all its cosmopolitanism and future-orientation, Busch has remained down-to-earth as a company. It still has its headquarters in rural Maulburg, in the border triangle between Germany, France and Switzerland, and supports local communities not only there, but at all company locations worldwide.