In future, Osko will rely on an all-electric Allrounder 720 A for the large-scale production of plant pots. The high-performance machine from Arburg achieves high injection speeds of up to 400 millimetres per second and is therefore also interesting for use in the packaging sector. In addition, the energy requirement is reduced by up to 45 per cent compared to standard hybrid machines on the market.

Sales Manager Packaging at Arburg, Joachim Branz, advises: „In times of high electricity and material prices, anyone who wants to manufacture in an energy-efficient and resource-saving manner should keep an eye on energy costs as well as acquisition costs. The lower the price of the products and the larger the quantities, the more this applies.“ Short cycle times in conjunction with significantly reduced energy requirements can shift the predominantly hybrid machine park of packaging article manufacturers in favour of fully electric, high-speed machines in the future.

New injection unit brings all-electric drive

At its Ochtrup site in Münsterland, Germany, Osko relies on an electric Allrounder 720 A in the „Ultimate“ performance variant with the new size 1300 injection unit and 3,200 kN clamping force. „We want to achieve an optimum cycle time in the production of thin-walled plant pots - and at the same time make considerable energy savings,“ says Osko owner Ralf Ostkotte, defining the objective for the all-electric new addition to the machine park. Injection speeds of up to 400 millimetres per second and very high flow path-to-wall thickness ratios are possible thanks to the precise servomotors from Arburg's sister company AMKmotion possible. The four-cavity mould for the application comes from the Swiss company Glaroform, the automation from Arburg partner Brink.

45 per cent reduction in energy consumption

So what is the energy requirement of all-electric versus hybrid? To answer this question, the Arburg experts first compared an electric Allrounder 720 A with an injection unit 1300 with a standard hybrid packaging machine in the same clamping force range (3,200 or 3,300 kN). The result: with the same process and component quality, the energy requirement of the hybrid machine was around 68 kWh, while the all-electric Allrounder consumed around 37 kWh, which is around 45 per cent reduction in energy requirements is sufficient. Osko has recognised this savings potential in order to produce as economically and sustainably as possible in a market with notoriously low margins.

Post-consumer recyclate into plant pots

Demand for the plant pots from Osko GmbH is high far beyond Germany and the neighbouring Netherlands. The exhibit presented at the Arburg Technology Days 2024, which produced four thin-walled plant pots each with a wall thickness of around 0.45 millimetres from 100 per cent recyclate, also attracted a great deal of attention. Post-consumer recyclate (PCR) based on PP from plastic waste from household collections was used. Digital functions in the Gestica control system ensure stable processes and consistently high moulded part quality. The „aXw Control RecyclatePilot“, for example, compensates for fluctuating material qualities and ensures a consistently high moulded part quality. Consistently constant mould filling safe. When adding colours and additives, care is taken to ensure that the Plant pots remain recyclable and can be returned to the dual system after use leave.

Motivation energy efficiency

„Osko attaches particular importance to Resource conservation and energy efficiency and scrutinises the required use of energy in an exemplary manner,“ says Joachim Branz, describing the medium-sized family business, which also produces a large proportion of the electricity it uses itself using solar panels. Originally started in 1750 by company founder Joan Bernard Ostkotte with the production of clay pots, the company expanded to include injection-moulded plastic products in 1984. The company realised how much cheaper and faster it could meet the literally growing demand for plant pots, flower pots and flower bowls. Since 2005, Osko has completely dispensed with clay and has now become Specialised in lightweight and thin-walled articles.

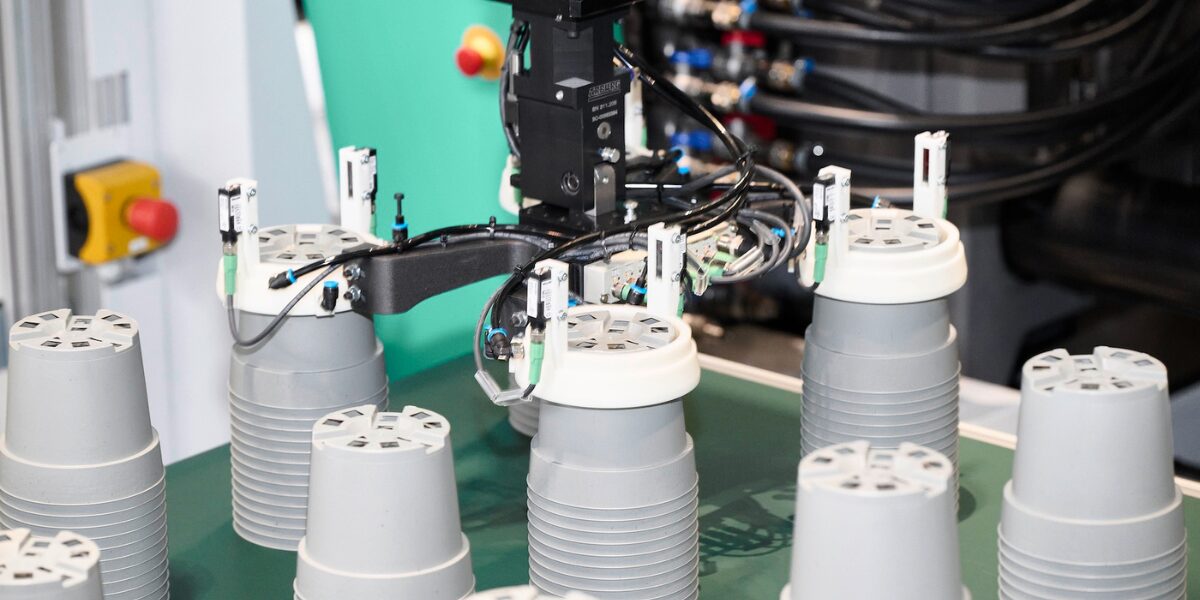

While a Multilift linear robotic system was used at the Arburg Technology Days 2024, the company in Ochtrup now relies on a special packaging automation system from Brink with a fast-acting side-entry robot. However, Arburg's additive expertise still comes into play for the gripper: the main component, manufactured using a 3D printer TiQ made from fibre-reinforced plastic filament, replaces aluminium. The four precisely fitting grippers were produced by a freeformer in a hard/soft combination. To remove the plant pots, the soft gripper part is „inflated“ with compressed air to fix and gently handle the moulded part.

Pioneering work in terms of energy efficiency

Minimised unit costs and cycle times are a prerequisite for the economical production of mass-produced items. „As a rule, it is primarily a question of philosophy and investment costs if hybrid machines are predominantly used for packaging products,“ observes Joachim Branz and stimulates:

„If you look at the overall savings potential over a defined period of time, high-performance electric machines can be the more energy- and production-efficient alternative, depending on the application. It is therefore worth taking a close look at the processes and individual applications and further developing your machinery in a planned manner.“