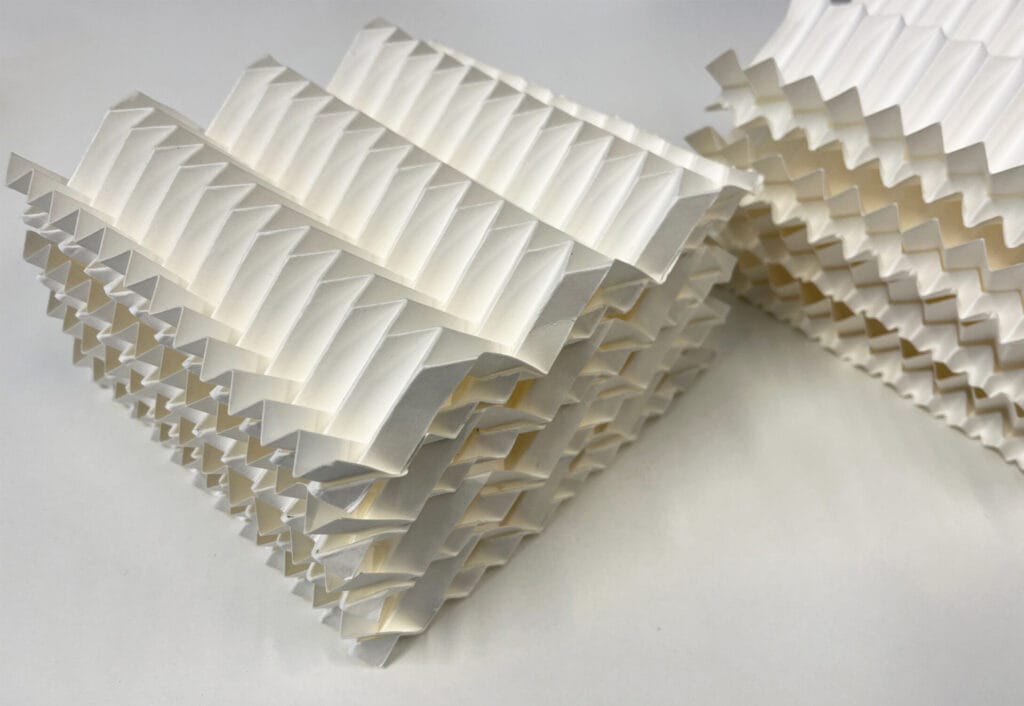

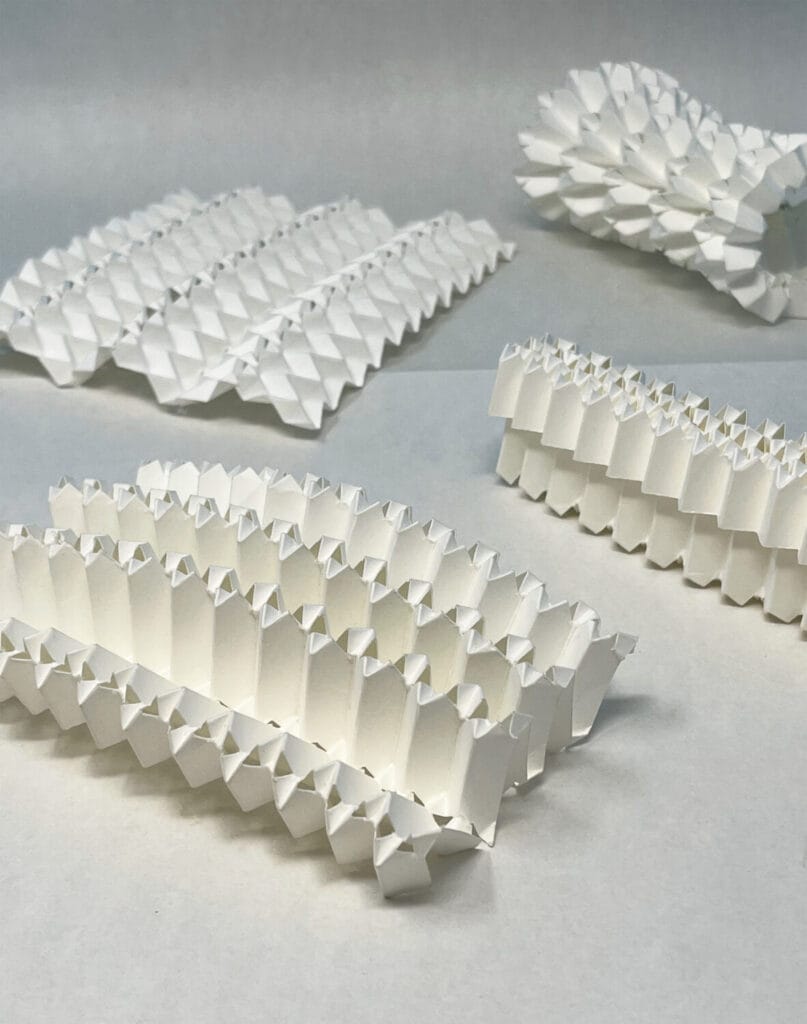

The Technical Research Centre of Finland (VTT), in collaboration with Aalto University and Finnish industry partners, has developed a new cardboard forming technology to produce roll-to-roll origami inspired structures for fibre-based packaging materials.

The origami folds can be used to Completely new properties of cartonboard can be achieved. The low weight and durability of the structures offer a visually appealing alternative to protective packaging materials such as plastic and expanded polystyrene. The aesthetics of the material have already attracted the interest of designers.

The FOLD and FOLD2 projects, in which 13 different companies, organisations and universities are involved in different phases, form the cornerstone for the renewal and expansion of the use of cardboard as a packaging material. The two-stage project began with the development of a machine for folding origami cardboard, and in the next phase of the project other materials are to be tested be developed. The result has been a resounding success, leading to new applications for cartonboard in the production of flexible, durable, versatile and sustainable packaging material.

„FOLD's technology is completely unique in the world. Origami folding transforms cardboard into a flexible, protective and visually appealing material that was previously unavailable for industrial production. The technology we have developed is also capable of producing foldable materials from recycled goods.“

Jarmo Kouko, Creator of the FOLD project and head of the research team at VTT.

The original inspiration for the project came to Kouko when he attended a packaging industry conference on various folding techniques. Traditionally, origami is made by hand, with the intricate and complex folds often taking several hours to complete. This intensive process would normally be a limitation for commercial packaging, but Kouko was inspired by the The idea of machine folding that could transform materials into protective, lightweight and visually stunning forms.

The Solution mechanically mimics the process of hand folding and offers the advantage of consistent precision and quality that would be difficult to achieve by hand. As the technology can be applied to a range of commercially available board grades, no changes to the materials used are required. „The Japanese Miura origami pattern that we have chosen is relatively simple, so it is easy to produce.s potentially suitable for folding many other materials. We have investigated the possibilities of developing techniques and models in which felt or PET film, which is often used for plastic packaging, can be moulded into the Miura shape. We have also carried out some preliminary tests for other materials, such as aluminium foil,“ Kouko continues.

Collaboration with the industry for a faster market launch

Eight industrial companies were involved in the FOLD project and participated in both development and financing. The current phase, known as FOLD2, began in March 2024 with continued support from a consortium of companies. The aim for the future is to extend the application of the technology to other materials and Partners throughout Europe for pilot projects and Global partners for the commercialisation phase after the completion of FOLD2.

„The packaging industry is very interested in FOLD, and the close collaboration with various companies enables us to move quickly from the innovation phase to practical application. If the project progresses as planned, origami board could be on the market within three to five years.“

Jari Räsänen, R&D Manager at Stora Enso, one of the companies involved in the project

Beautiful material inspires designers

In addition to its versatility and environmentally friendly properties, the FOLD material also inspires designers. Demo packaging made from origami cardboard has been already presented at the 2023 Design Weeks in Finland and the Netherlands, where the material was met with enthusiasm. For example, in applications for luxury items, such as in the cosmetics industry, the aesthetics of the packaging are an important part of the customer experience. FOLD offers consumers a high-quality unboxing experience, compared to traditionally used solutions such as bubble wrap and expanded polystyrene. also more environmentally conscious is.

„Folding cardboard opens up completely new possibilities for us in the development of fibre-based packaging, for example for the food industry. With our new Japanese owner, origami folding is a particularly interesting topic.“

Annika Sundell, Walki Group

„This project is a good example of the power of multidisciplinary collaboration. Solving problems associated with folding requires not only a Understanding the ideal geometric structures of mathematics, but also Knowledge of materials and modelling through design and engineering. In addition to practical applications, the unbiased handmade prototyping has also led to numerous new research questions. In addition to packaging solutions, the project results are also suitable for abrasive products and interior structures, for example,“ summarises Kirsi Peltonen, a mathematics lecturer at Aalto University who specialises in origami.

In addition to VTT and Aalto University, Anpap, Business Finland, Elomatic, Lumene, Metsä Board, Mirka, Orfer, Soften and Stora Enso were also involved in the FOLD project. VTT, Aalto University, Anpap, Business Finland, Marja-Suomen Taimituotanto, Mirka, Soften, Stora Enso and Walki are involved in the FOLD2 project.

Source: VTT