Sometimes the automation of packaging systems fails because of seemingly minor details, such as the efficient automatic changing of label rolls. The new JetSplice process offers a solution here.

The efficient design of labelling processes is an indispensable building block in the entire value chain. In this way Interaction of filling, packaging and labelling systems a sufficiently high efficiency of the entire system can only be ensured if the Roll change without machine downtime is possible.

Take booklet labels, for example: a seemingly small automation deficit in the packaging line, which can have a significant financial impact on the overall profitability of a system, is the Roll change for the labelling system. A manual reel change with machine downtime is not a sensible option, at least at medium and high speeds (from 100 labels per minute), both from a technical and financial point of view.

What's more, even for labelling systems with relatively low speeds (50 to 80 labels per minute), manual roll splicing is not economically viable in many cases. For example, rolls of the increasingly popular label brochures (booklet labels) often only contain 500 labels or even fewer due to the voluminous label format. The consequence of a lack of automation at this point is therefore frequent interruptions to the labelling process and a high labour requirement at the machine. A simple calculation example shows this: with 300 to 400 labels on a roll and a speed of 80 labelling operations per minute, the packaging line has to be stopped every four to five minutes during manual operation.

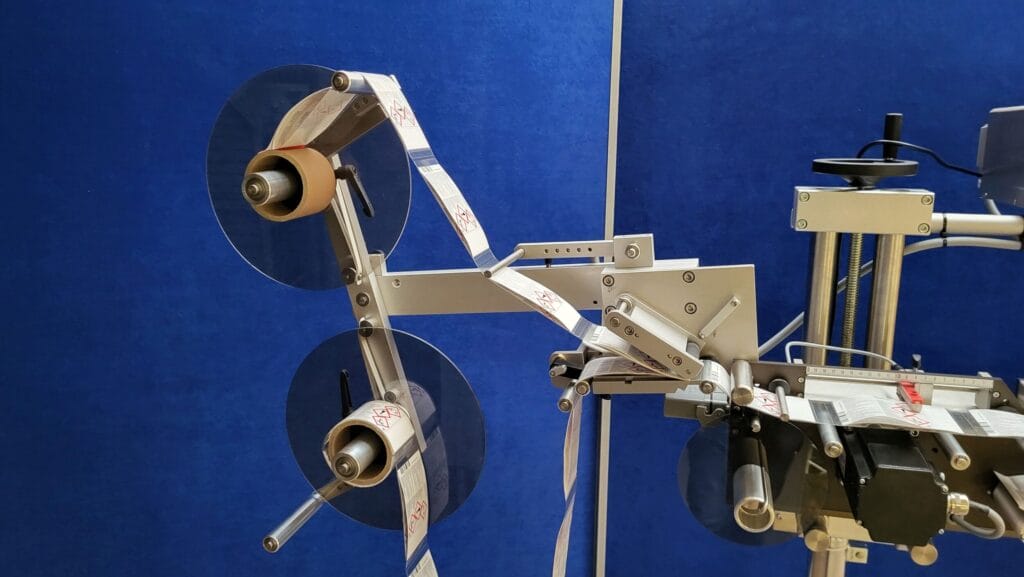

The new JetSplice process from Verpackungstechnik Jetter GmbH shows, how the automatic splicing process can be implemented simply and intelligently when changing reels. The product is based on the LabelLink splicing process from Jetter. In this process, the end of a label web is spliced to the beginning of a new web using the splicing tape in a special splicing head. In addition to the special JetSplice adhesive tape adapted to the new process, a newly designed splicing head is used, which was developed by packaging machine manufacturer b+b Automations- und Steuerungstechnik according to Jetter's specifications.

Technically simple and cost-effective splice head

Label webs from two separate rolls run together in the new splice head. When the upper one reaches the end marked by the JetSplice special adhesive tape, the beginning of the second web provided is spliced. Automatically glued on seamlessly, This allows the labelling process to continue without interruption. The process can then be continued by manually replacing the empty roll. The user has time to prepare the new roll throughout the entire running time of the active roll. There are no gaps on the connected label webs and the label spacing at the splice point corresponds precisely to the label spacing specified on the roll.

It is particularly important that no mechanically or optoelectronically controlled movements of splice head components are required to join the label webs. The JetSplice splice head is therefore technically simple and cost-effective. Thanks to the variably adjustable gap on the splicing head, the aforementioned booklet labels with their different booklet thicknesses can also be processed without any problems.

Change roles without stress

In addition to the splice head, the jetsplice process requires a device to hold two label rolls and optionally two spindles to wind up the empty tape on the labelling machine. Jetter supplies a simple solution for this, which can also be integrated into conventional labelling machines at a later date without any problems. Once the web has been automatically spliced, the attached roll is moved from the staging position to the working position and the next label roll is prepared for the next splice. The JetSplice developers have provided a similar principle for rewinding the empty tape as for the two unwinding spindles, so that the empty tape can be disposed of at any time without interrupting the labelling process.

Added value for both users and machine manufacturers

Jetter offers labelling machine manufacturers the components of the splicing process - unwinding, a small tape buffer that may be required for very high tape speeds, splice head and empty tape rewinding - together on or as separate units for integration on their respective labelling systems. For existing systems, the splicing process can be in the form of an independent unit next to the labelling system to use. After consultation with the manufacturer of the labeller, the components can be built as a stand-alone unit on a separate base frame or as an attachment directly to the label dispenser.

The Unwinder and splice head do not require their own power supply. The labeller drive is sufficient here. A take-off motor may only be required for belt speeds of 50 metres per minute or more. This unit replaces the standard unwinding of the labeller and can be adapted accordingly.

Source: Jetter