Adapa is expanding its SkinFreshTop portfolio with the new slim film for flat meat and sausage products and is positioning skin packaging specifically as a brand profiling tool in the premium segment.

Packaging is increasingly taking on a dual function in food retailing: it protects sensitive products and also serves as a visual quality feature at the point of sale. Adapa is focussing on this aspect with its SkinFreshTop portfolio. The highly transparent skin films are designed to make the product quality visible, particularly in the case of high-quality meat cuts, and support differentiated positioning in the premium segment.

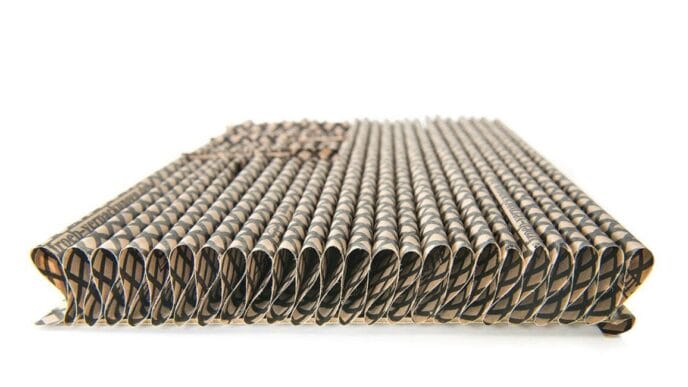

Skin packaging wraps around the product like a second skin and fixes it securely to the carrier. Thanks to the high contact transparency, the structure, cut and marbling remain clearly recognisable. At the same time, the technology enables upright presentation on the chiller shelf. In addition to the visual effect, product protection also plays a key role, as barrier properties and the choice of material make a decisive contribution to shelf life.

Barrier film for flat products

Adapa has recently expanded its skin portfolio with the SkinFreshTop Slim variant. The new high-barrier film is designed for flat and softer products with a height of up to 30 millimetres, such as fresh boneless meat cuts or processed meat and sausage products. According to the company, the film is highly transparent and glossy and can be processed on standard traysealers and thermoformers.

SkinFreshTop Slim is available in material thicknesses from 80 to 125 micrometres. Sealing is possible on product carriers with PE or PE peel sealing media as well as on mono-materials such as PP or PET. This should ensure a high level of process reliability in different packaging lines.

Source: Adapa