The new AMS adhesive measuring system from Robatech not only enables cost transparency and reduced adhesive consumption, but also reliably reports errors in adhesive application.

The Swiss manufacturer of adhesive application solutions brought the new product to the Measurement of the current consumption of hot melt onto the market at the end of 2019. The AMS is all about Green Gluing. It supports customers and adhesive manufacturers with data and analyses in the Optimisation of adhesive application quantities and brings transparency to the adhesive process.

The usual Safety margins for adhesive application can be reduced or omitted altogether without any loss of quality in the bonding.

Quick error message in case of deviating adhesive application quantity

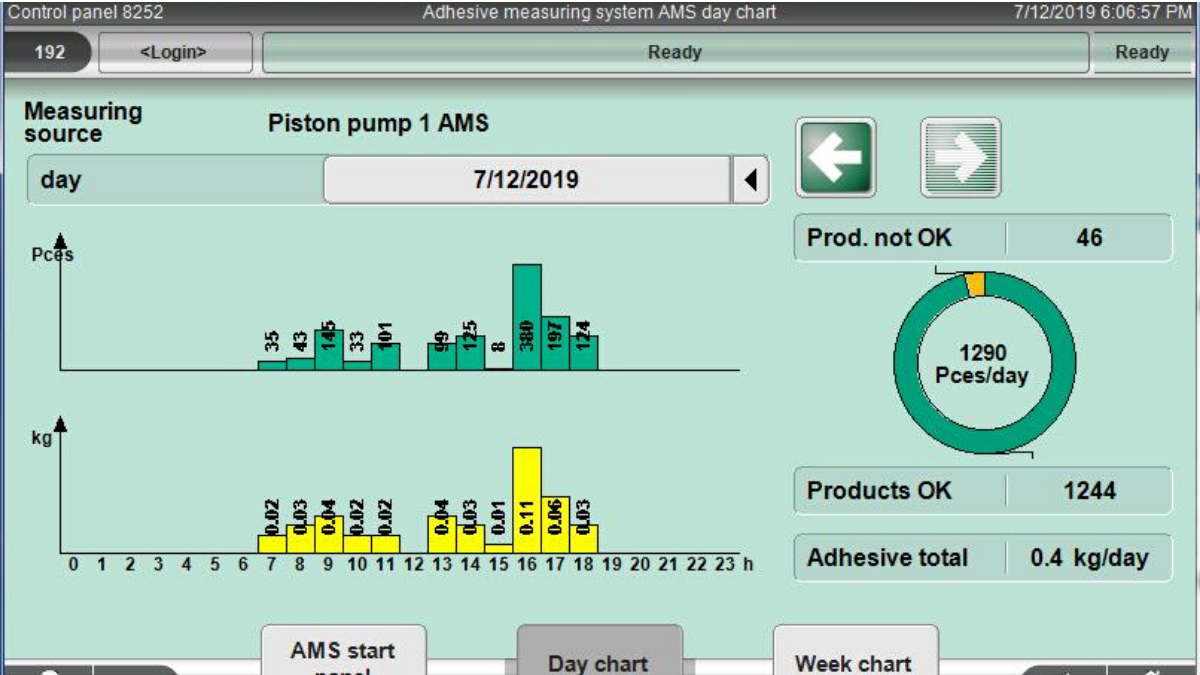

AMS measures the actual consumption adhesive and compares the data with the stored reference values from the configuration database of the Robatech Control System. If the applied adhesive application quantity deviates from the defined tolerance range If the adhesive level drops, a quick error message is issued. The adhesive measuring system thus increases sustainability in production and creates process reliability.

All measurement and configuration data is clearly displayed on the standardised user interface of the Robatech Control System and can be easily exported.

Two performance variants

AMS is available as an option for Robatech melters from the Concept-Diamond- and Concept stream line available. Depending on their requirements, customers can opt for the low-cost version with Piston pump KPC12 AMS or the more precise and faster variant with Measuring cell AMS-V decide.

[infotext]The Robatech Group, headquartered in Muri, Switzerland, is a leading global manufacturer of innovative and sustainable adhesive application solutions for industrial hot melt and cold glue application. Robatech has been producing and supplying high-quality control units, application heads, melting and dosing systems since 1975[/infotext].Source: Robatech