Sea Vision is focussing on AI-supported technologies in its presentation at interpack. Machine vision, traceability and process automation will play a central role. Visitors can experience the technologies in practice in Düsseldorf.

Particular attention will be paid to the new technology that is based on artificial intelligence algorithmswhich were developed together with ARGO Vision and are used in the inspection of lipsticks and the automated handling of lines. At the trade fair, customers will be able to experience these technologies in practice and learn how Shaping the pharmaceutical and cosmetic manufacturing processes of the future with AI can.

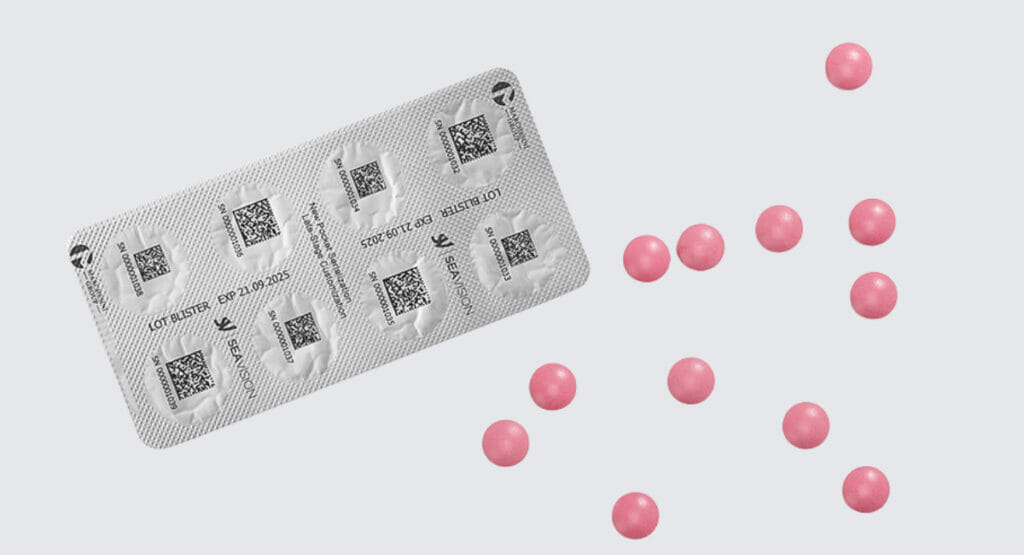

In the area of traceability, the main focus is on the Track & Trace software for blister packswhich enables the inline printing of serialised graphics on primary packaging together with complete aggregation down to pallet level.

Lipsticks are demanding products in terms of production and quality control. Artificial intelligence is intended to eliminate a large proportion of potential defects. The system of Sea Vision Group uses a semantic Segmentation of the areas of the lipstick (e.g. body, tip, neck, mechanism, etc.) to identify each possible defect pixel by pixel. This is achieved by categorising the areas and giving each area a name or "label". Each part or area of the image is classified by category and identified by a colour on the screen to provide the operator with immediate information about the areas being examined.

The System learns to recognise an ever greater variety of increasingly complex errorspiece by piece. Learning is done both on the basis of proprietary datasets - a mixture of real and synthetic images generated using the most advanced data augmentation and neural generation techniques - and by combining the different models and parameters observed over time.

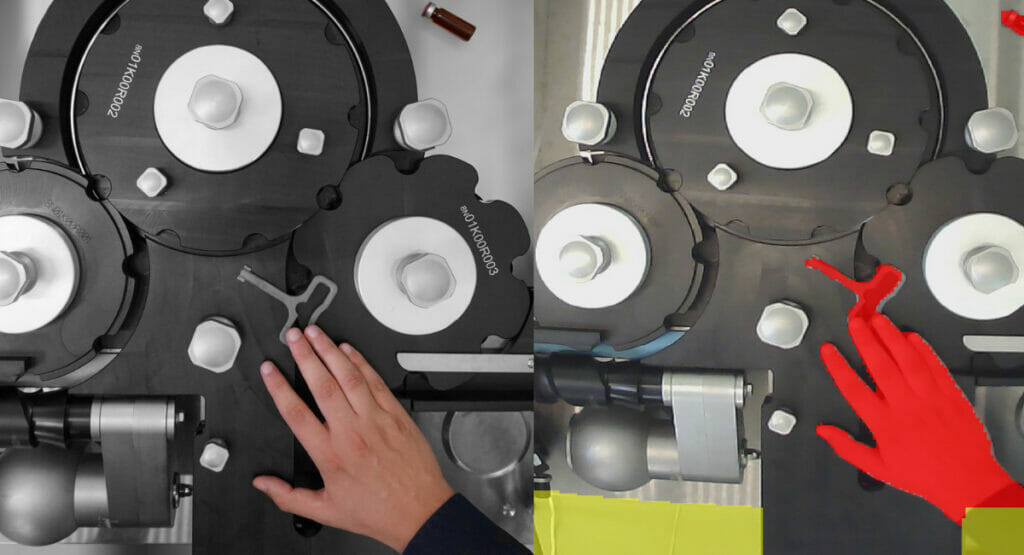

Line release is a crucial phase before the start of production. The aim is to ensure that the equipment and work areas are free of material and document debris. However, these stages still require manual intervention by operators to perform certain paper-based tasks and activities, which introduces the risk of human error. The need for greater security and smoother processes is the driving force behind Sea Vision's Smart Clearance technology. This solution will controlled by AI algorithms to automate the handling procedures and thereby avoid errors, reduce the time required and increase the OEE of production lines.

As part of the yudoo 4.0 software suite, the Smart Clearance technology is able to provide a Automatic, precise inspection of the working areas of the packaging line using cameras and sensors to highlight anomalies and provide visual feedback to the operator in real time. The system will be demonstrated on a high-speed rotary labeller RLF800 from the Marchesini Group.

Smart Clearance can Coordinating the movement of mechanical machine assemblieslocated between the cameras and the parts to be inspected. An immediate advantage is the ability to use a small number of cameras without having to install more to capture all hidden scenes. The system is enhanced by AI algorithms and overcomes conventional limitations in terms of reflections, shadows and different lighting conditions.

yudoo is a 4.0 platform that connects automation devices, machines, IT and control systems with each otherto control the entire pharmaceutical production process while collecting and analysing data to turn manufacturing and traceability insights into action and achieve results in the form of OEE improvements. The full version of yudoo includes Functions for the management of production lines, the integration of existing track & trace architectures for serialisation managementOEE performance analyses in real time and advanced KPIs based on business intelligence tools.

On the interpack will present the Blister Track & Trace technology for inline serialisation of primary packaging and aggregation down to pallet level. The solution will be installed on the complete blister packaging line at the Marchesini Group stand, including the entire line from the blister to the casepacker-palletiser. The novelty lies in the direct on-line printing via an on-board printer installed on the Integra 720 is a solution that complements the off-line printing introduced last year. The system controls the in-line printing directly on the blister, together with the control of the codes, and then automatically merges with the codes printed on the cartons, boxes and pallets.

The aim of the solution is to Combat the risk of counterfeiting in the primary packaging of pharmaceuticals and maximise investmentspharmaceutical companies have already undertaken to ensure that secondary packaging is traceable in order to guarantee 100 per cent security in the distribution of products along the supply chain.

Source: Sea Vision

More news on digital solutions

ePac invests 50 million dollars

LogiMAT 2026 showcases packaging as an intralogistics driver

Fruit Logistica 2026 attracts 90,000 trade visitors

CCL Faubel with new generation of logistics labels