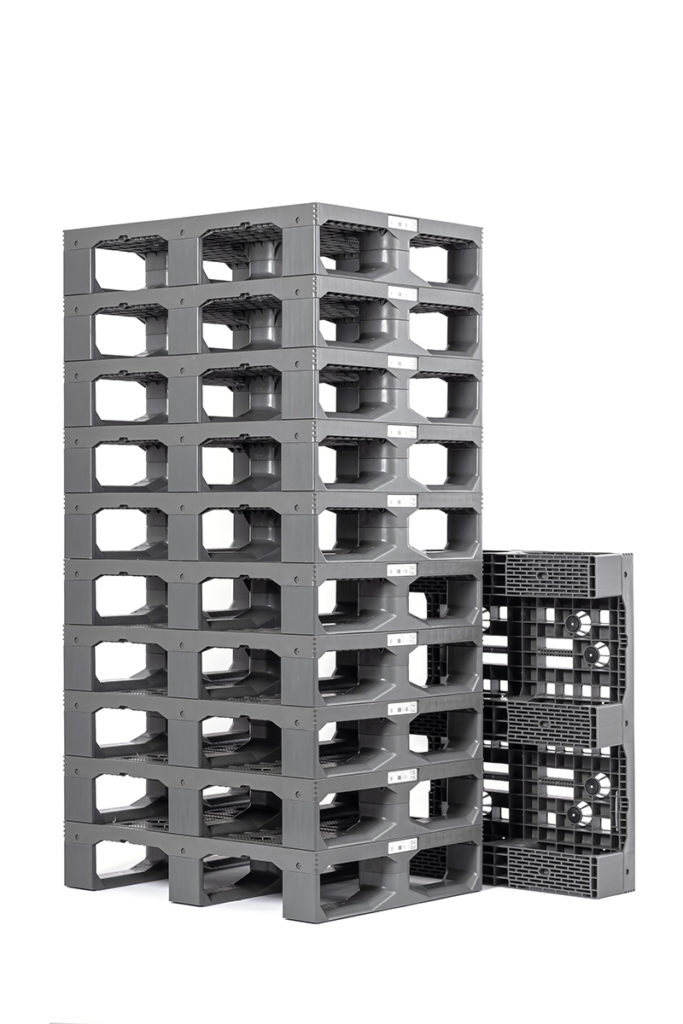

Aldi Nord and Aldi Süd are introducing the so-called „Kunststoff Düsseldorfer Palette“ (KDP) throughout the company, which is completely recyclable and already consists of around one third recycled material. The KDP is produced by Walther Faltsysteme.

From autumn 2020, both discounters will gradually replace the classic wooden pallet measuring 80 x 60 centimetres with a durable and more economical plastic version.

„The plastic pallets are technologically state of the art. A real innovation for the optimisation of supply chains in the food retail sector,“ says Stefan Ruhland, Director Logistics Management at Aldi Süd.

The pallet offers a static load capacity of up to 1,000 kilos and a dynamic load capacity of 500 kilos and is For all common conveyor systems suitable. A special contour is embedded in the pallet deck, which makes the KDP particularly easy to handle. compatible with the familiar reusable crates from the fruit and vegetable sector and offers particularly high slip resistance and stability. Carrying handles and anti-slip stoppers ensure greater safety at work and during transport.

Pooling system replaces exchange principle

Unlike the wooden pallets, the KDP No exchange principle. Instead the provision of the KDP for suppliers via a pooling system, which was developed by Polymer Logistics is operated. After each circulation, empty pallets are checked for damage and cleaned by the service provider. This means that the pallets also fulfil higher hygiene standards.

Another advantage: Integrated RFID chips and barcode labels allow each pallet to be recorded with pinpoint accuracy.

„The pooling service provider can track how many pallets are in the depots, at the supplier and at the retailer at any time. This also results in less pallet shrinkage,“ explains Arne Ringkowski, Teamlead Return Logistics at Aldi Nord.

Easy repair and recyclability

Düsseldorf pallets made of wood are usually no longer fit for use after a few cycles and repairing them is usually uneconomical. „Thanks to its modular design, the KDP can be repaired without much effort. Defective runners are simply replaced. Discarded elements are recyclable and are fed into a recycling process,“ says Arne Ringkowski. „We are convinced that our suppliers will also appreciate the advantages of the KDP. Visually, the new pallets are also a gain and ensure a more attractive appearance. Attractive product presentation in the branches,“ adds Stefan Ruhland.

Source: Aldi Süd