Edged, sharp or irregularly shaped food products place special demands on packaging films. Allvac has developed three new film solutions that offer high puncture and tear resistance and are designed to provide protection even for challenging products.

Foodstuffs such as crustaceans, meat with bones or sausage products with metal clips can put a lot of strain on packaging materials. Allvac is responding to this with three new film variants: Allflex SX, Allflex EX and Allflex SX Plus. According to the company, the materials have been specially developed for applications where standard films reach their limits.

Allvac relies on 11-layer structures

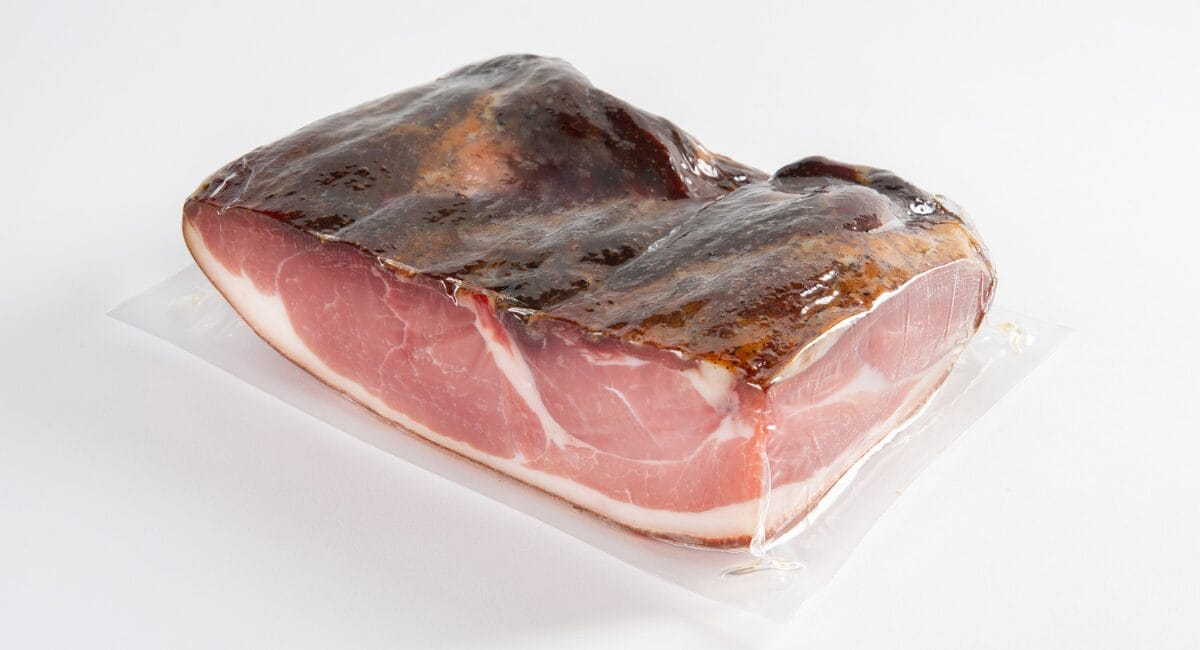

The Allflex SX and Allflex EX films are based on an 11-layer PA/PE composite structure and are available in thicknesses from 100 to 350 micrometres. According to the manufacturer, they are characterised by high puncture and tear resistance and are also easy to shape. This makes them suitable for meat with bones, hard cheese, bacon or seafood with a firm carapace, among other things.

The Allflex EX variant also has an EVOH high-barrier layer. Allvac thus improves the protection of particularly sensitive foodstuffs and extends their shelf life. The film is intended for applications where high barrier properties are required in addition to mechanical strength.

Allvac has developed the Allflex SX Plus film for particularly demanding applications. With a polyamide content of 40 per cent, this variant is even more resistant. It is used where even reinforced standard films are not sufficient, for example for fresh spare ribs or shellfish.

Wide range of applications

According to the company, the new film solutions can be used flexibly in various areas of the food industry. Thanks to different material thicknesses, they can be adapted to product-specific requirements and offer protection during the packaging process as well as during storage and transport.

Source: Allvac