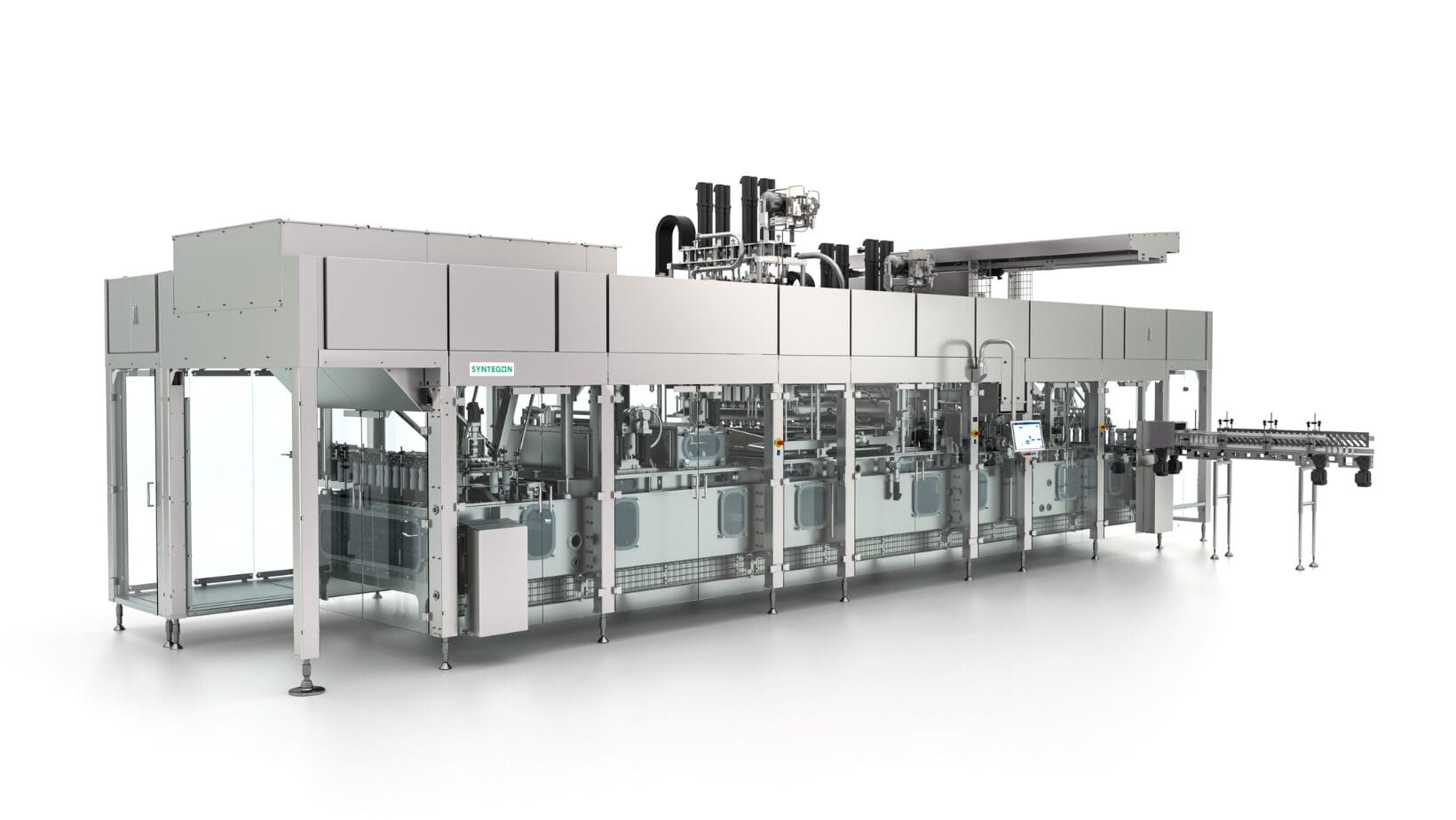

Ampack is breaking new ground in the aseptic filling of liquid foods: The Syntegon company is completing its modular portfolio with the flexible FBL filling machine for preformed bottles made of HDPE, PP and PET. In addition to baby food and clinical nutrition, the new development can also be used to gently fill milk- and plant-based drinks, dairy products and soups.

At Anuga FoodTec in Cologne, Ampack will be providing comprehensive information about the new technology, which will continue the success story of proven filling and sealing machines for preformed cups in the future. Versions clean to aseptic to continue.

„The FBL enables flexible and hygienically perfect production. A neck handling system adapted to the FBL for fast bottle format changeovers, as well as an innovative hygiene and maintenance concept, form the basis for this.“

Oguz Karcier, Product Manager at Ampack

There are a large number of liquid and viscous foods - each with different packaging requirements. The pre-moulded bottles available to manufacturers are correspondingly versatile: The options include different materials such as HDPE for particularly high barrier protection, PP and PET. With the FBL, Ampack is launching a multifunctional machine onto the market that Bottles made from all three materials with filling volumes between 50 ml and 1500 ml time-saving filling.

For this purpose, Ampack has developed a Neck handling system for faster bottle format changeovers further developed: The bottles, which have been erected in advance and checked for leaks, are fed into the cell boards via a gripper. The gripper grips the bottles by the neck and can therefore quickly hook different bottle types into the cell boards. Even malleable formats such as bottles with enteral nutrition can be transported reliably thanks to the neck handling. „The system can be Adapt to different bottle formats in just a few simple steps and thus enables efficient transport,“ explains Karcier. A simple maintenance concept makes a decisive contribution to productivity: Elevating dosing stations ensure efficient inspection and maintenance of critical components.

Gentle dosing

Ampack has also come up with an innovation at the dosing stations: In addition to numerous fillers for highly sensitive and easy-to-dose products, the FBL offers gentle product filling. „Some liquid foods, such as clinical nutrition, form a lot of foam during filling. To prevent foaming, we have developed a special dosing process. The result is low-foaming filling for the highest possible output“ emphasises Karcier. Depending on the filling volume, the FBL can fill up to 36,000 bottles per hour. The FBL also features the tried-and-tested SmartFill dosing concept, which impresses with its high filling accuracy and simple handling.

Thanks to its design in accordance with 3-A requirements, the filling and sealing machine fulfils the highest hygiene standards. Its innovative hygiene concept makes a decisive contribution to this and also increases production intervals thanks to long-lasting sterility. For the safe filling of sensitive products, the FBL separates production and mechanics in accordance with Ampack's innovative tunnel design. Equipped with an additional sterile chamber, to minimise the risk of food contamination and ensure greater product protection.

However, the FBL can be combined with other systems without any separation. Like all Ampack systems, the filling machine is equipped with interfaces that enable Simple integration with upstream and downstream machines mechanically and electronically. As a system provider, Ampack assembles the lines completely - from bottle production to screwing, sleeving and shrinking the film through to secondary and tertiary packaging.

Source: Syntegon Technology

Ampack at Anuga FoodTec: Hall 7.1, Stand D080