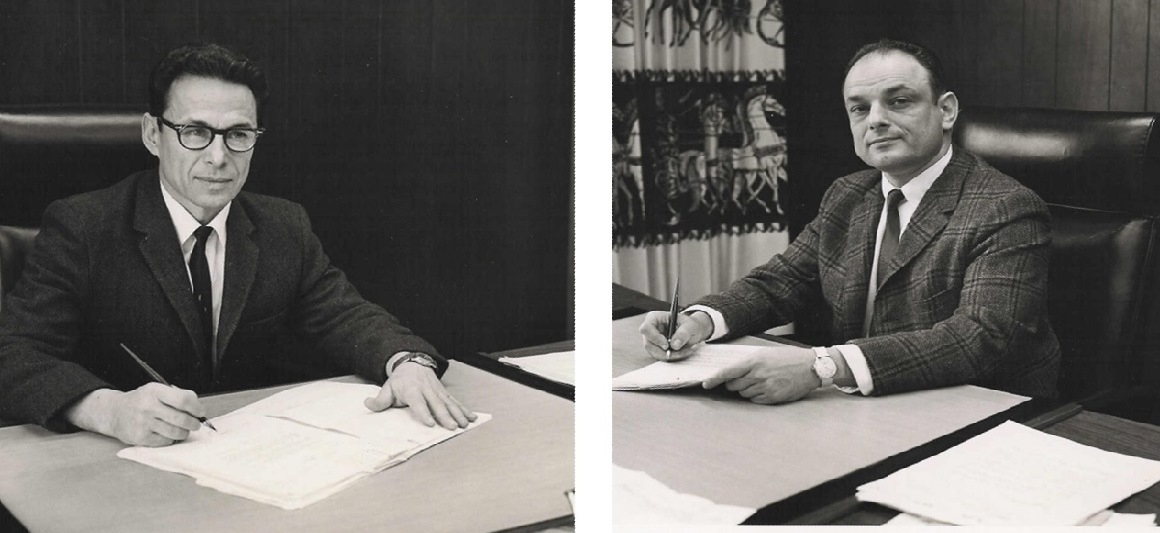

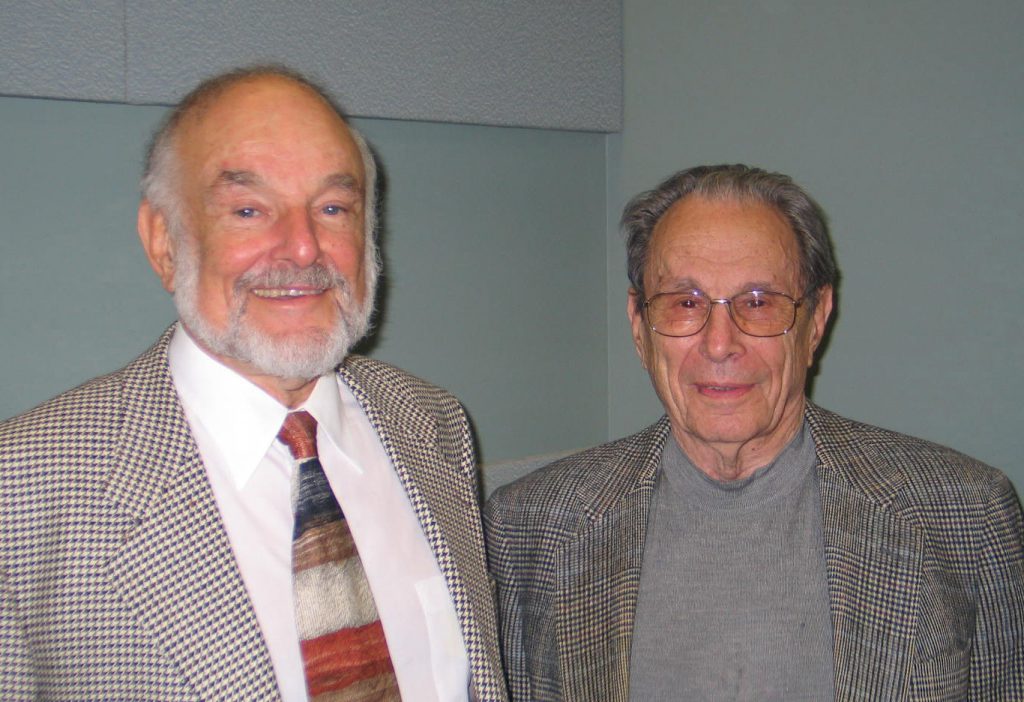

In the early 1960s, two young New Yorkers realised that the time was ripe for the development of a technical solution for the automated packaging of small parts in PE bags. With their idea of the Autobag chain bag, they were gripped by start-up fever and shortly afterwards laid the foundations for the success story of Automated Packaging Systems (APS). Today, it is one of the world's leading full-service providers of system solutions for automated pouch packaging.

At the beginning of the 1960s, the global demand for plastic packaging exploded and PE bags began their triumphal march through packaging technology, which continues to this day. However, many users were concerned that the bags were difficult to open and did not allow quick filling. Small and mass-produced parts manufacturers in particular were therefore increasingly calling for technical alternatives to manual packaging.

In 1962, the Hershey brothers and Bernie Lerner worked feverishly on a technical device for the Serialised packaging of small parts in PE bags, which was to replace the manual labour that had been common up to that point. Finally, they had the brilliant idea: they wound dozens of bags, sealed on three sides, onto a cardboard roll as a continuous chain and built the first simple device to go with it, with which each bag could be opened by means of a blower after unwinding and thus easily filled. A perforation made it easy to separate the bags.

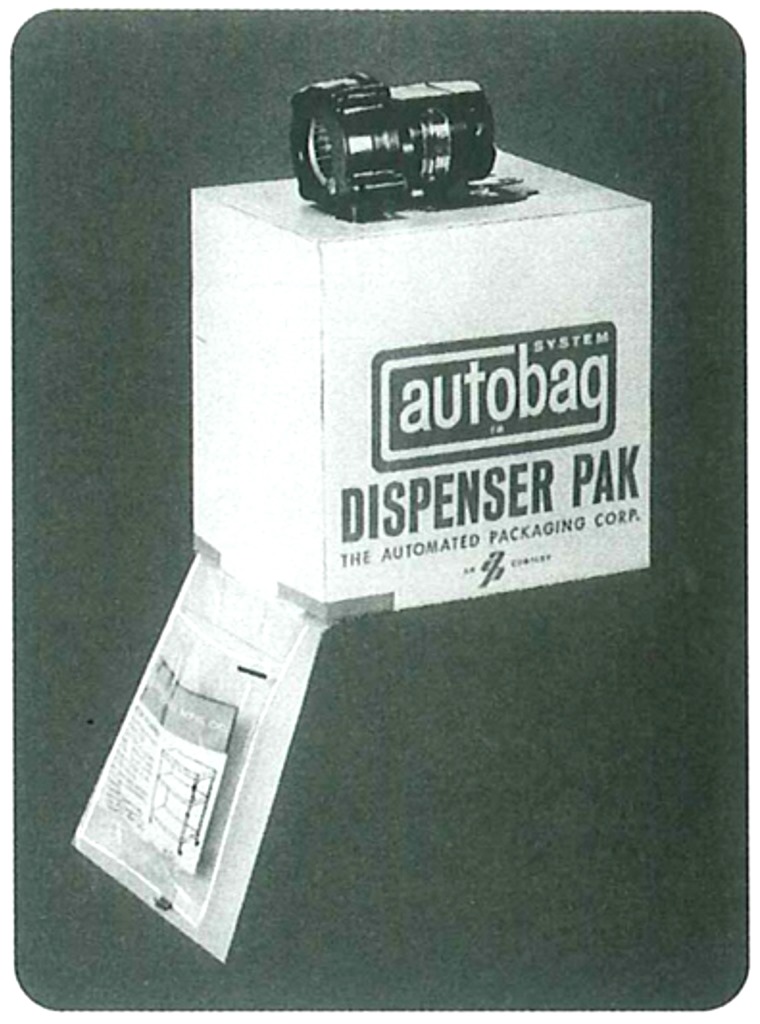

The first tests already showed that the Lerners were able to work with the principle of „Perforated chain bags from the roll“ were spot on. They moved their workshop into a larger garage and founded their company Automated Packaging. They christened the prototype of their first machine, little more than a cardboard box with a winding shaft and small blower from army surplus, Autobag. It was soon to become synonymous with a globally successful business model.

After the brothers had found the right man to build up a distribution network in sales strategist Arthur S. Gould and were able to attract Herb Crother and Ridley Watt from the then already established American Packaging Corporation (formerly American Bag & Paper) as investors, the way was clear for the further development of the Autobag concept.

In order to benefit more from the investor's infrastructure, the Lerner brothers moved their company Automated Packaging Systems to Hudson, Ohio, in 1963, where the Autobag went into series production: now with a stable housing made of sheet metal, improved mechanics and completed with a device for heat-sealing the filled bags.

First steps towards automation

Many industries gratefully accepted this technical innovation in the field of pouch packaging and sales took off very quickly. At the same time, Automated Packaging is increasingly focussing on the topic of automation and is able to launch the H-100 in the early 1970s. First automatic pouch packaging machine on the US market. It is quickly well received, as it can significantly increase productivity when filling PE bags thanks to its output of up to 35 bags per minute.

Equipped with a counting unit and weighing module, the H-100 marks the first technological milestone in the company's history. In view of the growing technical complexity of its machines, the company decided only a short time later to set up its own customer service department with trained technical staff. With this step, Automated Packaging has a complete range of machines, pouches and service and, just a few years after its foundation, embarks on the path to becoming a system provider. The company thus became the pioneer of an entire industry. Towards the end of the 1970s, it signalled its new self-image by changing its name to Automated Packaging Systems (APS).

On the way to the world market

Motivated by the success of the H-100 and the positive response of US customers to the system philosophy, Automated Packaging Systems began its international expansion in the early 1980s. A joint venture with a British company finally gave Automated Packaging Systems access to the global market in 1984. In the years that followed, numerous subsidiaries and production facilities were established in North and Latin America, Europe, Asia, Africa and Australia.

„This period also saw the founding of the German subsidiary, which is now based in Braunschweig and is responsible for sales in Austria, Switzerland and Eastern Europe,“ reports Jens Pfeiffer, who has been General Manager of APS Germany since 2001. APS's range of systems quickly met with great interest on the German market. His System philosophy As a result, it is also expanding its range of solutions for feeding, weighing and conveying technology. „To this day, we are making it easier for users to integrate our pouch packaging machines into their packaging processes,“ explains Jens Pfeiffer.

Automated Packaging Systems is able to firmly establish itself in the German mechanical engineering, electrical engineering and electronics sectors as well as in the automotive industry with its complete range of products. In the mid-1990s, the HS 100 Excel followed with its modern design, which set the standard in industrial pouch packaging for many years. It already had an operating display and an electronic control system. Over the course of the 1990s, the expansion of the pouch selection to include additional formats and materials also became more important, making pouch packaging technology from Automated Packaging Systems attractive to new market segments time and again.

„Over the course of the 1990s, our management clearly recognised that the development of further bag types would become at least as important as innovations in the area of machines. We therefore set up our own pouch production facility in England,“ reports General Manager Jens Pfeiffer.

Innovative drumbeat

The company is starting the new millennium with an innovation campaign and regularly demonstrates this at the interpack (Düsseldorf) and FachPack (Nuremberg) trade fairs: the pouch packaging machines are becoming more intelligent, faster and more flexible - and the variety of pouch options is constantly growing.

A real sensation in 2003 was the presentation of the Autobag AB 180. Equipped with maintenance-friendly electronic and pneumatic modules, digital control, touchscreen and self-diagnosis, the packaging system is the pioneer of a new generation of machines. It processes up to 80 bags of different material thicknesses and formats per minute, has a motorised unwinding unit for precise bag guidance and automatic bag insertion (AutoThread). The variants of the Autobag AB 255 process large bags (up to 400 mm wide and up to 660 mm long) shortly afterwards.

„All the machines we offer are consistently designed in accordance with the criteria of the EU Machinery Directive. We were one of the first packaging machine manufacturers to realise a wide range of safety-related modifications and further developments to our machines in line with the European Machinery Directive 2006/42/EC. This means that APS machines also guarantee important features in terms of technical and occupational safety,“ emphasises Jens Pfeiffer.

Pressure unit included

With a view to the efficient packaging of small batch sizes, the company is presenting its One-Step concept, which gives the Autobag 180 and Autobag 255 their own printing units for the first time. This allows each bag to be printed with individual product information and dispatch codes from the customer's database before filling and sealing.

„In this way, we have integrated the printing of the pouches into the packaging process, which means an enormous increase in productivity for many applications,“ says Jens Pfeiffer. The experts have opened a completely new chapter in the history of pouch packaging technology with the development of their high-speed SPrint and FAS-Sprint-Revolution machines. With outputs of up to 120 pouches per minute, these complete systems, which are equipped with their own feeding and printing technology, are not only moving into completely new speed regions, but are also, depending on the version, more efficient than ever before. Customised for use in food and industrial technology.

The AirPouch systems for the production of air cushions and bubble wrap for product protection have also been added to the portfolio. Jens Pfeiffer adds: „With many new pouch types and film materials for protection against corrosion, UV radiation, static charge and mechanical damage, we have made pouch packaging technology and protective packaging attractive for other areas of application, such as the packaging of sensitive industrial items or electronic components.“

Launch of the fulfilment generation

With the further development of its SPrint, Automated Packaging Systems offered the market the first representative of a new generation of highly integrated fulfilment systems that also print labels, generate invoices, feed inserts and advertising material to process large order quantities and thus produce individual orders or large batches of ready-to-ship bag packaging at record speed. Last year, Automated Packaging Systems presented its Autobag AB 255 as another representative of these automated lines as a fulfilment solution for e-commerce retailers.

What happens next?

General Manager Jens Pfeiffer has a very clear picture of the The future of pouch packaging technologyIn addition to the expansion of fulfilment technology for e-commerce and products for the convenience market, we are pushing ahead with the development of new bag types made of PE and PP as well as the highly efficient processing of resealable bags. In order to further perfect our complete range, we are also currently strengthening our service areas of analysis expertise, sampling and testing. And I can already reveal: On 1 January 2016, we will be opening our new company headquarters for the DACH region and Eastern Europe in Wolfenbüttel.„