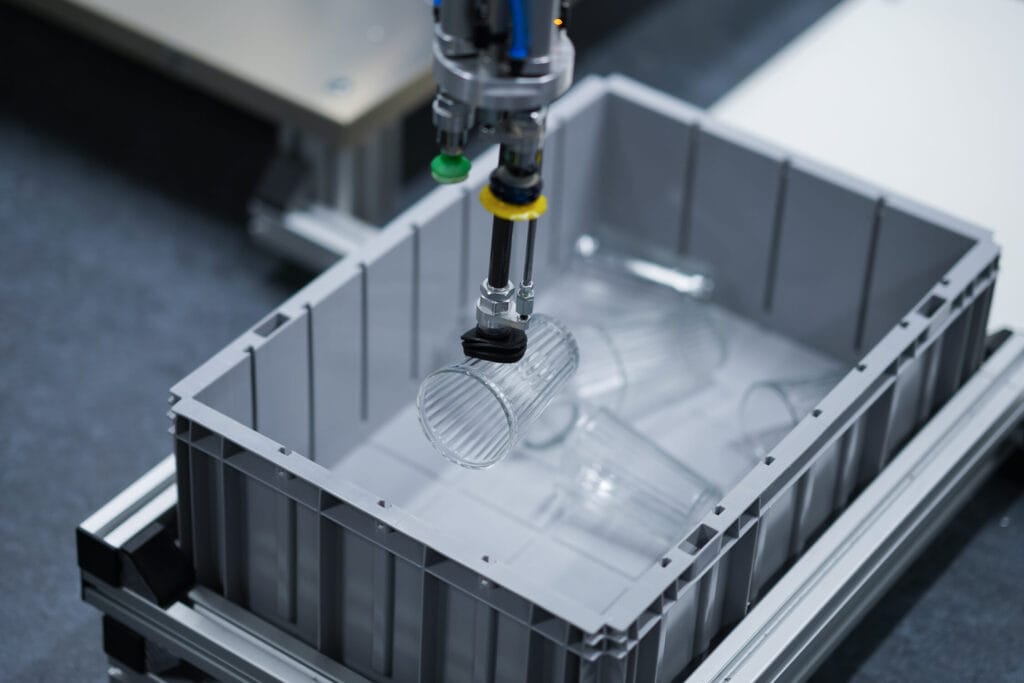

Pick and place robots have long been standard equipment in industry. However, conventional systems are often customised to specific product sizes and shapes. With the help of AI, they can also operate in more complex environments with changing product characteristics.

Whether in e-commerce, the automotive industry or the pharmaceutical sector, pick and place systems need to be modernised in order to be able to operate autonomously and without human intervention, even in more complex production environments. In particular, this includes reliably categorising different product groups and independently finding suitable solution strategies - even for previously unknown objects. To achieve this, the robot must, depending on the product to be handled can switch flexibly between different gripping systems. The solution should also be able to recognise damaged items and sort them out automatically. In the event that an employee is still required for instructions or feedback, communication between man and machine should be straightforward and in real time. To put all this into practice, the implementation of AI is required.

How pick and place robots benefit from AI

The combination of AI and picking robotics significantly increases efficiency in order fulfilment. Technology leaders in the field of order picking robotics are focussing in particular on on the use of Vision Language Models (VLMs). VLMs are a Combination of AI-based visual and linguistic models, which are able to link images with their corresponding text descriptions. If action parameters are added to these models, a Vision Language Action Model (VLAM) is created.

An example of a VLAM from robotics is PickGPT from the Stuttgart-based software developer Sereact. The system is designed to understand natural language and, on this basis, to precisely analyse its environment and act autonomously. Even if the model works autonomously, seamless communication with human employees via voice and text commands is supported at all times.

AI-based pick and place systems also work on the basis of zero shot learning. Zero shot learning is a concept from machine learning that enables a model to be used, recognise new classifications of objects without having seen them during training. This enables the system to react and act independently to unknown picking situations in practice. Products are identified and interpreted in real time based on their appearance. It takes into account their specific properties such as shape, colour, weight or texture and independently selects the appropriate picking method.

This enables the system to distinguish between heavy and light items and place them in the target bin accordingly. Faulty or damaged items are automatically recognised and sorted out. In addition, the system can move items that are difficult to pick by manipulating specific objects and rearrange the goods in the container, thereby minimising the risk of damage. Solve problematic situations without human intervention.

AI-based systems are characterised not only by their high degree of automation, but also by their compatibility. The software can be integrated into various warehouse systems and is also hardware-agnostic. It is therefore also suitable for warehouses with traditional pick and place systems, as it can be can be integrated with a wide range of robot components.

The use of traditional pick and place robots promises logistics companies a significantly higher throughput by automating picking processes and working productively around the clock. However, this is usually no longer enough these days. Technology companies such as Sereact are therefore going one step further: with the development of AI-based systems they increase productivity, especially in environments with more complex picking processes. Industries with a wide range of products such as e-commerce in particular benefit from AI, as it makes it possible, decide between different product types and independently find the right handling solution.

However, AI-based systems are not only beneficial in particularly complex environments, but also offer clear advantages over traditional systems even in simpler applications. Even with minor deviations, such as different placements of products in the container or varying shapes - be it one apple that doesn't look like another - their systems show their strengths. They ensure reliable and efficient handling that outperforms conventional solutions, thereby increasing productivity across the board.

Source: Sereact