Lantech will be showcasing its automation solutions for shipping packaging at Fachpack in Nuremberg in September. The systems are highly efficient and optimise the dispatch of goods with faster wrapping and fewer operator errors.

The CI-1000 automatic inline carton erector combines high performance with flexibility. Users achieve a speed of up to 25 cycles per minute and can process many types of cardboard, The possible dimensions range from 200 mm x 150 mm x 150 mm to 500 mm x 325 mm x 520 mm. The machine masters the challenge, despite the changing nature of the corrugated board as well as varying temperature and humidity. always produce rectangular cartons. This gives the packaging maximum stability and makes it ideal for the logistics chain. The cardboard bases are sealed with hot glue or adhesive tape.

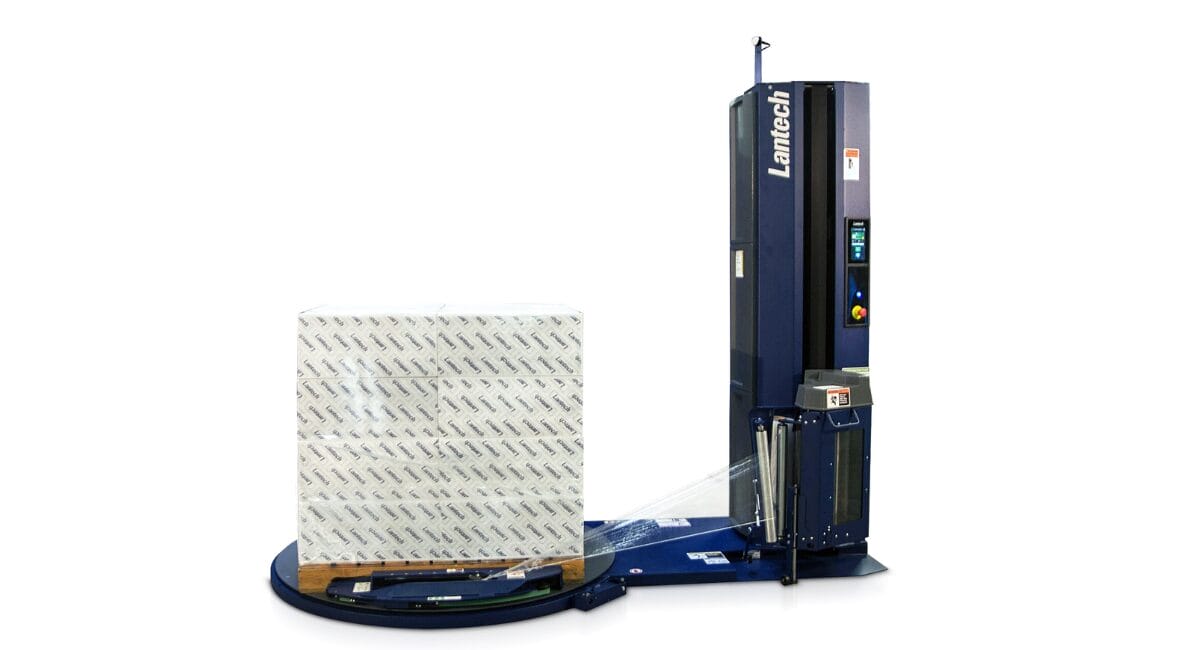

Stretch wrapping machines are a prerequisite for professional load securing on pallets. Lantech offers an efficient packaging solution with the new QL-400XT semi-automatic stretch wrapper. Compared to conventional machines Each wrapping process is shortened by two minutes, because the film is automatically attached to the pallet and cut off after wrapping. This is made possible by the patented „XT Cut and Clamp“ function, which is purely mechanical and requires neither compressed air nor electricity.

Another advantage is the intelligent „Load Guardian“ control system. The system creates special profiles with the appropriate retention force for frequently occurring loads. User save time and avoid operator errors. The QL-400XT stretch wrapper processes up to 35 loads per hour with a maximum diagonal of 1830 mm and a maximum height of 2030 mm. The processed film can be pre-stretched by up to 300 per cent.

Source:Lantech

Lantech at Fachpack: Hall 1, Stand 1-415