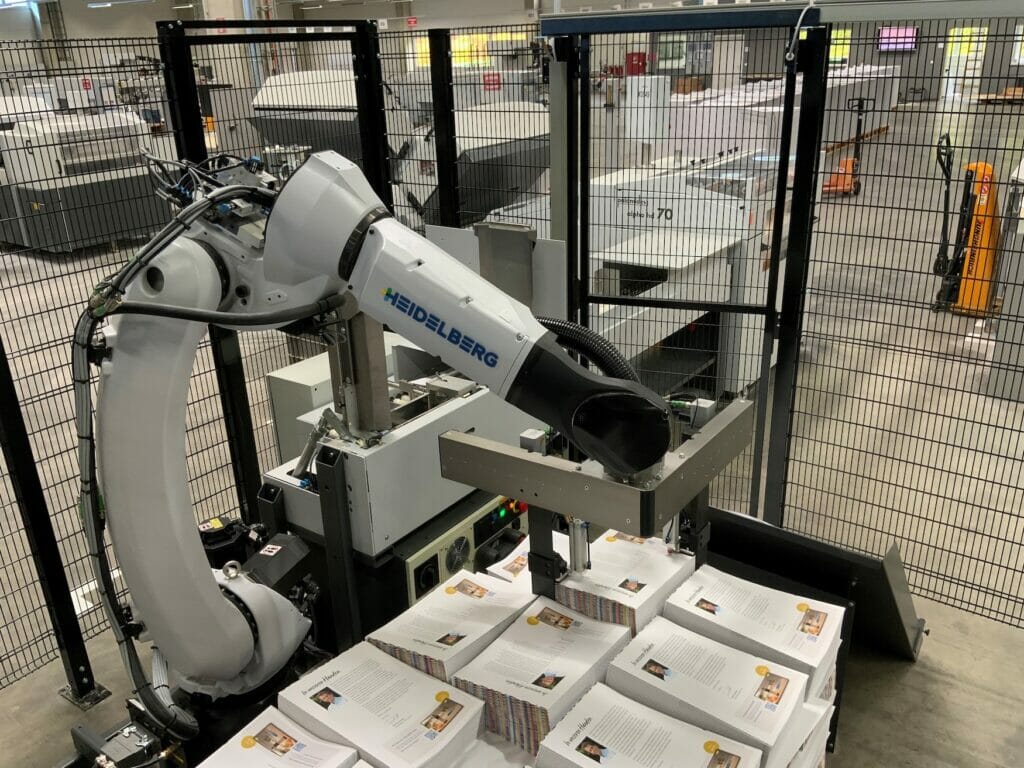

This is what print shops have been waiting for: the Stahlfolder P-Stacker from Heidelberger Druckmaschinen AG. The robot technology picks up stacks of signatures at the exit of folding machines and places them on pallets fully automatically.

In the meantime, numerous customers are now producing with the P-Stacker in push-to-stop operation. At Aumüller Druck GmbH & Co. KG in Regensburg and Meinders & Elstermann GmbH & Co. KG in Belm have been using the P-Stacker for several months. In both commercial printing companies accelerates highly industrialised production in push-to-stop mode.

As First manufacturer worldwide has Heidelberg the push-to-stop principle on the Speedmaster sheetfed offset technology introduced and transferred to the Stahlfolder folding machines. Aumüller Druck and Meinders & Elstermann have integrated their processes seamlessly into Heidelberg's Prinect technology. This applies both to the automated control and monitoring of production and, in the opposite direction, to the recording of operating data.

P-stacker at Aumüller raises gross output

Large volumes, split into many small partial runs, characterise the order structure at Aumüller printing. The company produces on four Speedmaster sheetfed offset presses in push-to-stop operationThe company folds on five high-performance folding machines, two Stahlfolder TX 82 and three Stahlfolder TX 96, which went into operation in 2014 and 2016. On all five buckle plate folding machines, a PFX feeder feeds the sheets into the folding system in an underscaled formation.

"Thanks to the Stahlfolder TX technology from Heidelberg, we have doubled our output from the previous 40,000 sheets per shift to 80,000 sheets."

Volker Dollinger, member of the management team at Aumüller Druck and responsible for production

With the P-Stacker, production output has now been significantly increased once again, by around 25 per cent. Up to 110,000 16-page signatures leave the Stahlfolder TX 96 every shift. The Machine produces largely autonomously. For push-to-stop production operation, the many signature changes are signalled to the system via a printed barcode, which is read by a camera in the feeder of the folding machine. This is done with up to 18,000 sheets folded per houron a par with sheetfed offset. Volker Dollinger states: "Thanks to the Elimination of physical activity the machine operators are ready to maximise the output of the folding machine depending on the folding subject and paper quality."

Autonomous with the Stahlfolder P-Stacker

The Work flow thanks to the suitable settling pattern additionally optimised. Different Signatures are automatically recognised and placed in separate batches. For print runs of up to approx. 4000 signatures, a five-pack scheme with five packages per layer applies, as Volker Dollinger says. Either two towers are formed on one Euro pallet or one tower each on two one-way pallets. If the print run exceeds approx. 4000 signatures, the twelve-pack scheme is used, whereby the P-Stacker builds a tower with twelve packs per layer on the pallet.

Depending on the further processing on a saddle stitcher or perfect binder, the signatures must be placed with the first page on top or on the bottom. While this task was previously the responsibility of the operator of the folding system, the P-Stacker now takes over, with the robot arm gripping the packets in the set-up unit either from the front or the back. The same applies to the Automatic insertion of intermediate layers by the P-Stacker.

Meinders & Elstermann far ahead in digitalisation

What counts when it comes to automation Meinders & Elstermann is one of the pioneers. In 2013, the company commissioned a Stahlfolder TX 96 with a shingled sheet feeder as a pilot system. The next première followed in August 2018: a Stahlfolder TH 82 was the first folding machine in the world to be equipped with the Push-to-Stop functionThe system automatically switches from one signature to the next.

Meinders & Elstermann has now taken a further step in the direction of a highest possible net production output and two Stahlfolder TX 96 and one Stahlfolder TH 82-P were each equipped with a P-stacker. One last Gap in an end-to-end automated process has been closed. Thanks to the robot, push-to-stop production can be fully utilised on the folding machines.

"Our aim is to increase the Overall Equipment Effectiveness (OEE) across the entire production process from 40 to 60 per cent."

Jens RauschenManaging Director at Meinders & Elstermann

The company commissioned the first P-Stacker as a pilot customer. The results were convincing. To achieve at least fifteen per cent faster was produced on the Stahlfolder folding technology compared to machines without a P-stacker. The company subsequently equipped two further folding machines with a P-stacker.

Production on the two Stahlfolder TX 96 machines is monitored by just one person, while the employee on the Stahlfolder TH 82-P works in parallel with the folding machine on a Polar PACE cutting system. "Our employees used to move up to six tonnes of paper in one shift on the folding machines," says Jens Rauschen, "Today we leave this heavy labour to a robot."

The editions at Meinders & Elstermann vary greatly. In many cases, the signatures of several different orders are placed on one pallet. In order to meet the delivery deadlines in the best possible way, the Time-optimised sequencehow the printed sheets are produced on the Speedmaster presses and how the printing plates are output on the Suprasetter is determined by the finishing process. This is Digital workflow control at an advanced stage. The P-Stacker plays a key role in this seamless process. Jens Rauschen appreciates it: "The Prinect technology and the production technology from Heidelberg help us to standardised production and still retain the individual character of customer orders. in view.

"With the P-Stacker robotics in combination with our Stahlfolder folding machines we are closing a significant automation gap and continue to drive autonomous print production and the Smart Print Shop forward."

Jörg DähnhardtHead of Postpress at Heidelberg

https://www.heidelberg.com/global/de/index.jsp

https://www.aumueller-druck.de

https://me-druckhaus.de

Heidelberg - More news

Heidelberg takes over service for Schubert in Brazil

Study shows: paper packaging is becoming significantly more important

Heidelberg acquires technology and trademark rights from Polar Mohr

Networked label printing