At Anuga FoodTec, sensor specialist Baumer is presenting new solutions for the food and beverage industry, including a world first: a sensor that saves resources, increases food safety and prevents production downtime.

Heat-resistant process sensors for CIP applications, perfect timing for container changes in warehousing, Smart engineering from food processing to packagingSensor specialist Baumer presents solutions for the food and beverage industry at Anuga FoodTec in Cologne.

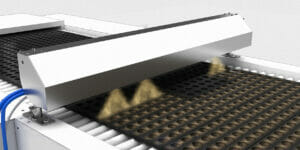

The new PAD20 reliably reports when mobile transport containers are empty and therefore the perfect time to change containers, for example in yoghurt production. The principle is simple, the technology behind it smart: The sensor detects even the smallest air and gas bubbles in the process medium and thus prevents pumps from running dry and system failures. At the same time, the containers can be emptied completely. This increases system efficiency and reduces product loss while maximising process reliability and quality.

Saving energy and media with CIP

How do manufacturers reduce costs in CIP applications? With high-precision, robust sensors, for example. The new PAC50 process sensor from Baumer, for example Reliably measures conductivity even at 140 degrees Celsius. Thanks to its compact design and streamlined sensor tip, the robust sensor reduces the flow resistance in the cable and is ideal for Suitable for small production systems in the food and beverage industry.

Like other Baumer sensors, the PAC50 via IO-Link as standard. This allows additional data such as temperature to be recorded for process monitoring and communicated to the control system. Thanks to Dual Channel, users can use the PAC50 Analogue, digital or simultaneous operation via both channels. With the PAC50, Baumer thus offers maximum flexibility and high investment security.

The time pressure for machine and plant manufacturers in the packaging sector is enormous. Here Baumer as a full-service provider for the packaging industry. Because Baumer sensor solutions offer maximum flexibility. This starts with the smart sensors. One example: Thanks to the high functional reserves, an optical sensor can reliably detect changing, demanding surfaces - reflective, transparent, matt or uneven. For the system manufacturer, this means that they can Use the same Baumer sensor for different application requirements and changing packaging materials. This reduces complexity in production and makes servicing easier.

Source: Baumer

Baumer at Anuga FoodTec: Hall 7.1, Stand A038 B039

Anuga FoodTec 2022 - More news

Mondi at Anuga FoodTec for the first time

Wrap pizza and enjoy pizza

Flexible labelling and inspection

Dosing dips and sauces