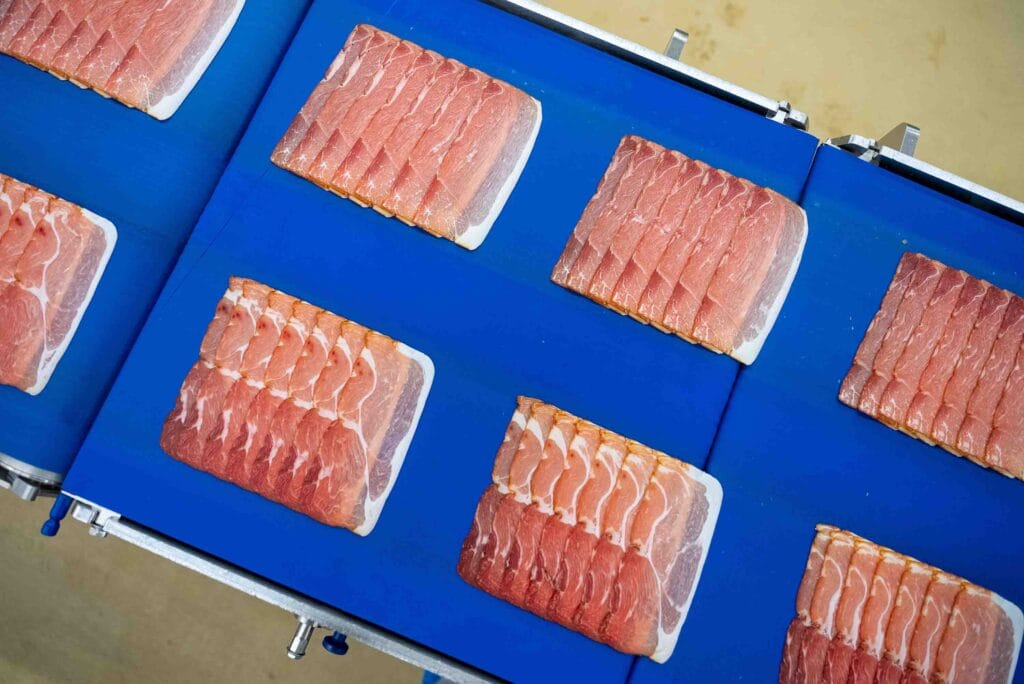

With recyclable mono-materials as well as material-reduced folding packaging for sliced ham, Bell sent out a clear signal some time ago in terms of sustainability. Now the Peel PET floatable from Südpack has been „discovered“. As part of the pilot project, the initial focus is on packaging slices of Black Forest ham.

Why did Bell Deutschland GmbH & Co. KG was one of the first suppliers in the food industry to opt for Südpack's latest product innovation? „Because we need a sustainable packaging concept for our high-quality ham specialities and, if possible, one that is also sustainable. of the most sustainable packaging concepts on the market want,“ explains Stephan Holst, Head of Marketing at Bell Germany.

Bell Germany is one of the leading suppliers of raw ham. The savoury delicacies, such as the German classic Black Forest ham, are produced, refined and packaged by Bell Germany. at a total of four locations in Germany, They are marketed under the „Abraham“ brand. The German branch of the Bell Food Group is also responsible for marketing other international charcuterie specialities from other Bell organisations on the domestic market. The fresh meat business for French beef under the well-known „Gourmet naturel“ label is also based here.

Development into a European group

The Bell Food Group is not only one of the leading European manufacturers of meat and convenience products, but the long-established company is also the market leader in Switzerland. Around 13,000 employees at 65 locations in 14 countries generate annual sales of more than four billion Swiss francs. „Our roots go back to 1869, when Samuel Bell opened his first butcher's shop in the centre of Basel. Today, our range includes fresh meat, poultry, charcuterie, seafood and ultra-fresh, fresh and long-life convenience products. With brands such as Bell, Eisberg, Hubers, Hilcona and Hügli, we provide millions of consumers with a wide range of enjoyable moments every day,“ emphasises Stephan Holst.

Sustainability: Peel PET floatable

As part of the pilot project with Südpack's solution, the initial focus is on packaging slices of Black Forest ham, with plans to expand to other specialities of the company in the future. Specifically, the previous PET-PE/multilayer thermoformed packaging will be replaced by an overall concept that made from a mono-APET bottom film and the PET-floatable top film exists.

„Peel PET floatable is a floating top film. Together with mono-APET bottom films, this results in a recyclable overall concept and a sustainable alternative for the safe packaging of sliced sausage, ham and cheese in peelable thermoforming and MAP packaging.“

Martin Schuler, Head of the Food Business Unit at Südpack

Strong product features

Due to their lower density, the top films can be separated from the material stream of the APET bottom film in the recycling process. can therefore be recycled by type. In terms of performance, pack security and processing, the PET-floatable lidding films are among the best.

As the product name suggests, the Peel PET floatable is easy to peel off the tray, does not tear when opened and does not roll up. „Opening behaviour plays an important role for consumers, both for reasons of convenience and with regard to the value of the packaging,“ emphasises Martin Schuler. The fact that when using No major adjustments in the machine area are also an advantage. This is because the peelable top films can be easily processed on Bell's machines. This has been confirmed by comprehensive tests on a wide variety of lines on site.

Recyclability as a success factor

Due to the good separability and the low weight of the top film in the overall packaging recyclability rated at over 75 per cent by an independent institute. It is already clear that Bell is well on the way to the future with the new solution: „There are already packaging guidelines from various retail companies demanding solutions for APET bottom films with a buoyant top film,“ confirms Stephan Holst.

At three other Südpack pilot customers The concept is also currently in the implementation phase and, as with Bell, the individual process steps have run smoothly so far. From the initial idea, starting with profitability calculations to testing, stage checks of the best-before date and tightness, right through to the final industrial test including packaging printing: „At four months for the entire project, we are well on schedule,“ summarises Martin Schuler. We are now eagerly awaiting the implementation in the normal production process in order to gain long-term insights.

Source: South pack