Raw materials and recyclates from different sources make it difficult to control extrusion processes. With the „Visco-P“ inline viscometer from Promix Solutions, the process can be stabilised and monitored.

During the process, characteristic values such as Mass pressure, mass temperature, extruder speed, layer thicknesses and similar parameters recorded and analysed if necessary. However, the actual material properties, which can change due to material composition, additive and colour content, temperature, pressure and shear, are not measured and therefore cannot be used for quality assurance.

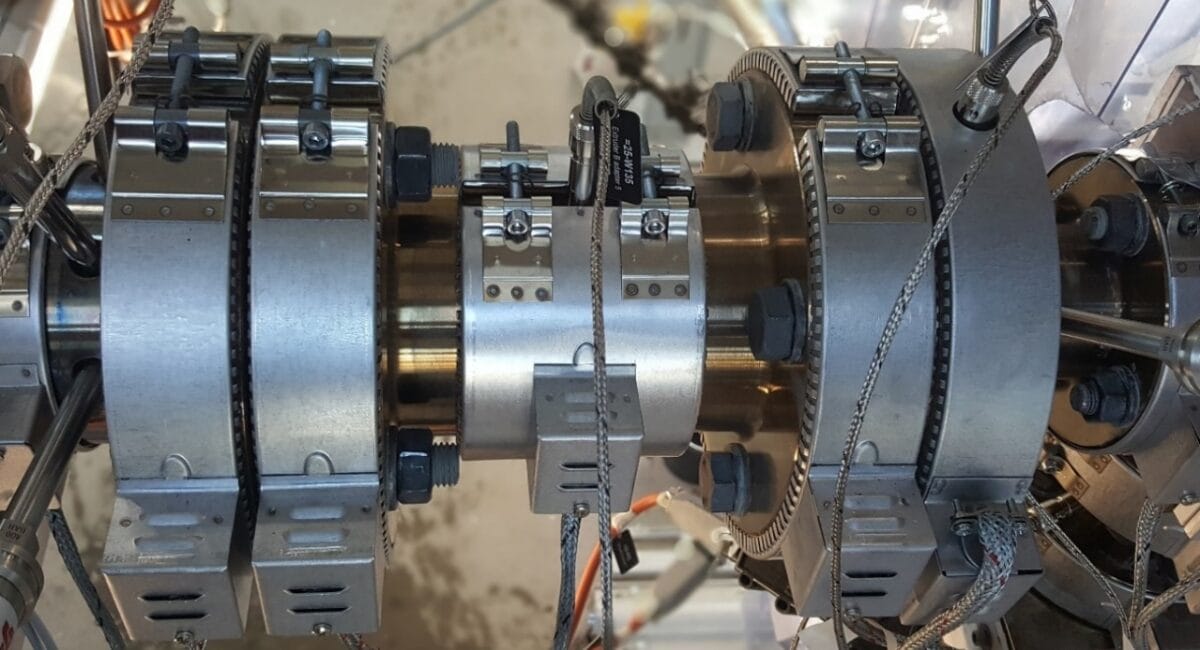

The Visco-P inline viscometer from Promix Solutions is helpful for quality in extrusion in two ways. Firstly, the installed measuring module homogenises the polymer melt and secondly it measures the real viscosity of the entire melt under process conditions and in real time.

The measuring modules specially adapted to the process homogenise the melt including added additives and colours. Of course, this also applies to mixtures of virgin material, B-goods, recyclates and regranulates. Another side effect is the equalisation of the temperature across the pipe cross-section. All these effects lead to a more uniform end product and can lead to savings in colour or additive dosing.

The measuring module also serves as a capillary for online viscosity measurement. Using known process parameters such as material type, flow rate, mass temperature and the pressure loss across the measuring module, the real viscosity is determined and displayed in real time as a graph and numerical value is displayed. In addition to the viscosity, the current melt temperature and the shear rate are displayed graphically. All other important parameters are displayed and saved as numerical values.

The conversion from real viscosity to solution viscosity (IV) for PET is also included, as is the conversion of viscosity to MFR for polyolefins and similar materials. This makes it easier for the user to compare the displayed values with the specifications.

User-selectable upper and lower limits for the viscosity trigger an alarm and show the operator the current deviations from the target value. Subsequent adjustments and their effects on the process and therefore the viscosity are displayed directly on the Visco-P and make it easier for the machine operator to make the necessary adjustments. Corrective measures to optimise quality.

Overview of important data

Since all relevant data stored for 12 months If the data is analysed after production has been completed, the corresponding evaluations can also be read out and assessed. The Visco-P offers three options for this. The data can be sent directly to another control unit via an external interface (FieldBus, ProfiNet, ...) and processed there. The data can be read out via TeamViewer or a USB stick, saved and analysed by an external computer. The third option is integrated in the Visco-P and creates a report on the viscosity with all relevant framework conditions and statistical evaluation with maximum value, minimum value, average value, deviation, Cp and Cpk. In addition, the viscosity is graphically displayed over the observation period with upper and lower limits.

The Visco P is therefore a supplement to quality control before and after production. The improved mixing of the components with simultaneous monitoring of the viscosity means that the Processing of recycled material or viscosity-influencing additives such as chain extenders for PET facilitated.

The Visco-P is compatible with all common extruder designs and can be retrofitted to existing systems. It can be used for almost all polymers and is very easy to operate.

Source: Promis Solutions