As an exhibitor at Fachpack and Powtech, the Beumer Group is presenting a new digital solution for process optimisation, condition monitoring and maintenance for conveyor technology and end-of-line packaging lines.

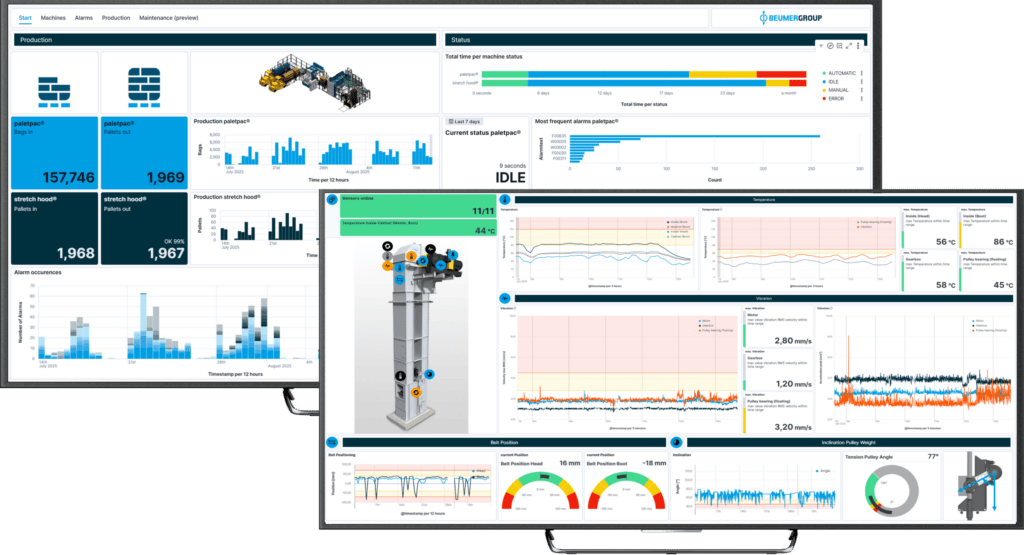

With Beumer Guardian, the company presents a digital solution for condition monitoring and maintenance. Customers can choose between two variants:

Guardian Advanced for companies that want to monitor and control their machines independently.

Guardian Performance, where the Beumer experts in the Global Monitoring Centre monitor their customers' systems in real time and intervene proactively.

Both solutions provide live data on machine status and process performance, recognise deviations at an early stage and support the efficient planning of maintenance intervals. This minimises downtimes, increases availability and creates investment security.

Flexibility in terms of costs and operation

Guardian offers a wide range of analyses - from automated reports to complete documentation for audits. Flexible pricing models such as pay-per-use or rent-to-own make it easy to get started and make the solution interesting for companies of different sizes. Guardian is embedded in the Beumer Group's Lifetime Partner Programme, which offers customers worldwide an end-to-end service.

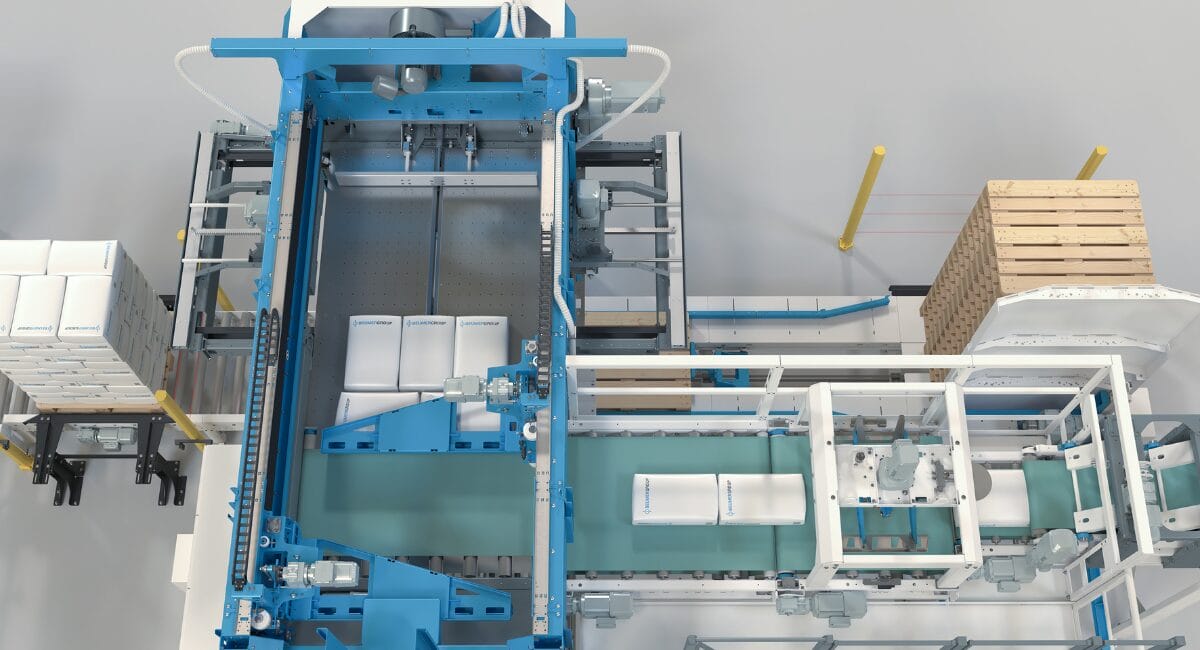

Palletising with precision

In addition to digitalisation, proven end-of-line systems will also be in the spotlight. The Paletpac systems stack bagged goods precisely and at high speed. The Robotpac robotic solution offers maximum flexibility when palletising different containers such as trays, buckets or cartons. Both systems are characterised by process reliability, high availability and user-friendliness.

Product protection thanks to stretch hood technology

For safe transport, Beumer will be exhibiting the Stretch Hood A stretch bonnet system. It not only protects pallets from dirt and moisture, but also ensures transport safety with highly stable film bonnets. The optimised film processing also reduces the amount of material used, which saves costs and conserves resources.

Source: Beumer Group

Beumer Group at the Fachpack/Powtech 2025: HaHall 9, Stand 465