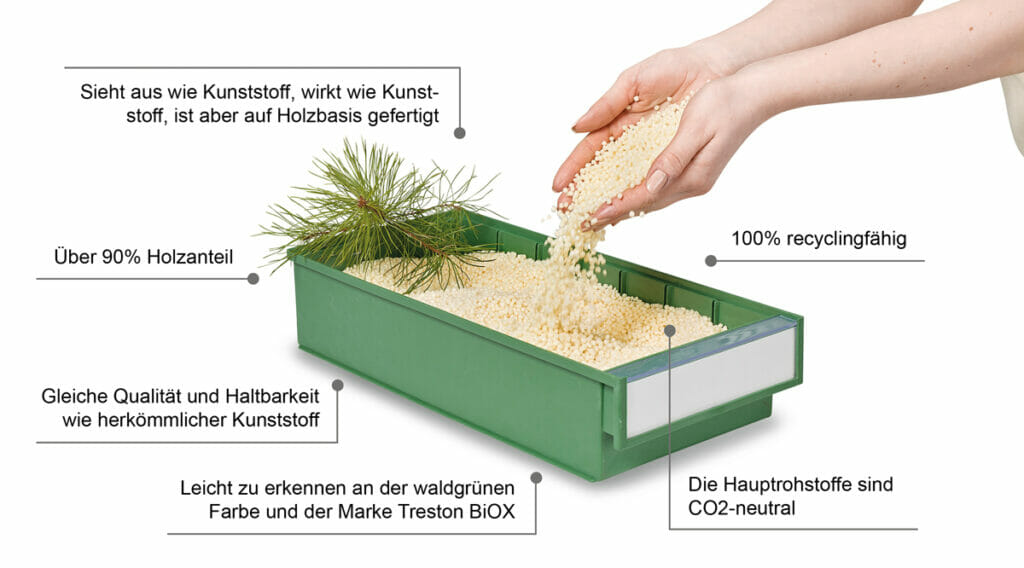

Treston is launching an industry first: a wood-based bioplastic container for industrial use. Industrial customers can thus opt for environmentally conscious storage and reduce their consumption of non-renewable resources and their CO2-footprint.

The CO2-neutral material of the Biox container consists of more than 90 per cent made from renewable wood-based materials, residues from pulp production and cellulose fibres from sustainably managed forests. The quality, look and feel of the containers are identical to conventional plastic containers.

„I am delighted that we are driving change and are able to offer our customers new carbon-neutral material options. Treston has always stood for high-quality, durable workspace solutions that reduce the consumption of our planet's resources. We also pay attention to our manufacturing processes. For example the heat recovered from the plastics manufacturing process, to heat the factory premises. Our long-term goal is to provide our customers with a completely CO2-neutral industrial workplace.“

Dirk Jonsson, Managing Director Treston Germany

The provider of ergonomic industrial workstations and storage solutions is initially launching „forest green“ storage boxes on the market. Further options for storage solutions will follow in autumn. Treston has set itself the goal of developing environmentally friendly, CO2-neutral alternatives to all fossil-based plastic products and parts. The long-term goal is to achieve a completely climate-neutral workplace to make this possible. Treston also offers storage solutions that are made from 100 per cent recycled plastic.

Joint development work

The material for the Biox containers comes from UPM, a global company in the forestry industry and leading manufacturer of fibre composites. The material for the transparent label plates and cross dividers is supplied by the Finnish start-up company Woodly provided. The joint development work with Treston is This is a first for both companies in the production of wood-based bioplastic products for industrial use.

„We are delighted to be working with Treston to develop the first product made from UPM Formi EcoAce for industrial use. The material can easily replace fossil solutions, as the quality and properties are identical to those of non-renewable alternatives. The big advantage is that the material is CO2-neutral. The Treston BiOX containers prove that the new sustainable materials are also reliable and of high quality in industrial and professional use.“

Ralf Ponicki, Director at UPM Formi

SourceTreston

Sustainability and green packaging - More news

Adapa presents sustainable solutions for PPWR implementation

Women in Packaging: Committed entrepreneur with team spirit

Smart packaging from conception to recycling

KHS relies on Plasmax barrier technology