At Automatica in Munich, Bluhm Systeme will be presenting its labelling systems with labels, ink and laser - especially for the current requirements in automation and robotics.

Traceability, error-free product identification and a transparent supply chain are key requirements in industrial production today. At Automatica - the leading trade fair for intelligent automation and robotics - Bluhm Systeme will be showing how these requirements can be met with its labelling portfolio. modular labelling systems, high-resolution inkjet printers and precise laser markers can be reliably fulfilled.

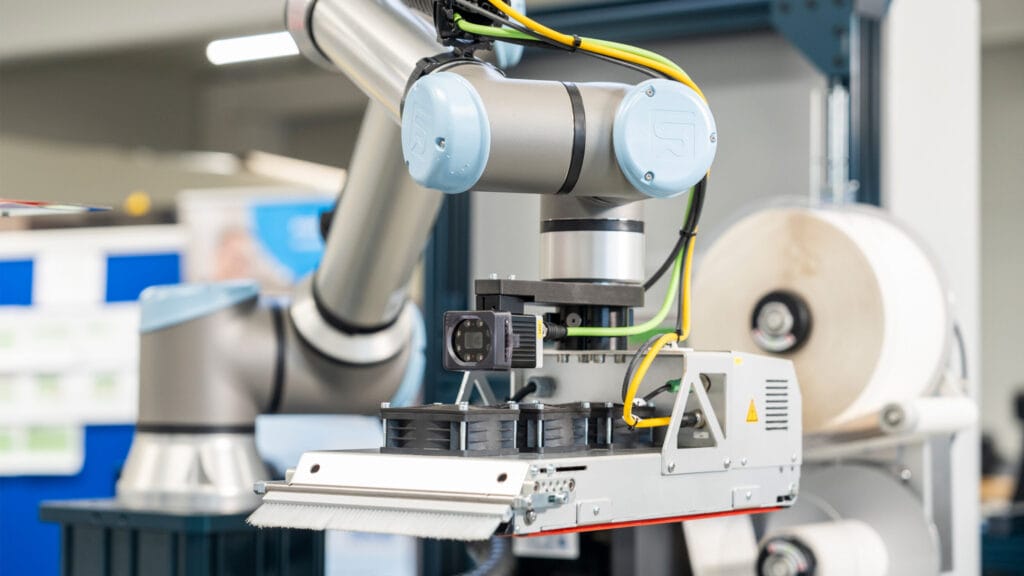

The systems on show are compact, energy-efficient and can be easily integrated into existing production systems via Industry 4.0 interfaces - also in combination with industrial robots.

Technologies for automation

The requirements for labelling are constantly increasing: serial numbers, 2D codes or shipping information must be clearly legible and permanently available.

Labelling systems from Bluhm Systeme label packaging, components and products fully automatically. With the Legi-Air 4050 E, Bluhm Systeme presents a energy-efficient all-rounder for high-speed applications before. A large selection of applicators enables any labelling position and speed. It can be configured so that faulty labels are automatically ejected and removed from the conveyor line. A housing for use in dusty, damp or cold conditions is also available.

High-resolution inkjet printers ensure sharp print images, even at high production speeds. The name of the Markoprint integra PP 108 already reveals its maximum print height of 108 mm. The piezo inkjet printer realises the high print quality required in many industries. large-format printing of text, 1D barcodes, 2D codes and graphics. User-friendly software enables convenient layout design and centralised printer control.

Labelling as the key to networked production

Clear labelling forms the basis for networked, automated production. Labelling processes are thus not only efficiently managed, but also transparently documented. The flexible adaptability to different product sizes and formats and the high energy efficiency of the systems also make an important contribution to the optimisation of sustainable production processes.

Source: Bluhm

Bluhm at Automatica 2025: Hall A05, Stand 301