At BrauBeviale, labelling specialist Bluhm will be presenting numerous new marking and labelling systems that can be used to label bottles, cans, cartons, KEGs and pallets.

The Full-service provider for professional labelling systems presents, for example, the new Pallet labeller AP182which uses a swivelling applicator head to label pallets on up to three different sides. Seven triggerable travel paths enable not only GS1-compliant pallet labelling on the front and side, but also labelling from one side with two different labels. Thanks to its intrinsically safe design, the AP182 requires neither a safety fence nor a safety barrier.

Product line for system integrators

In addition to labelling technology, Bluhm is also presenting new inkjet systems for easy integration into production systems. The Markoprint Integra One printing system with HP cartridge technology was specially developed for integration into packaging systems, such as those found in the food sector, and prints up to 12.5 millimetres high. The Markoprint Integra Quadro extends the advantages of the Integra One to a Printing system with four print heads. For different printing tasks, it can alternatively control two different print technologies - up to two print heads per print technology.

The latest print head in the Markoprint range is the Integra PP108 from ink manufacturer Seiko. With up to 360 dpi, it prints high-resolution text, codes and graphics at heights of one to 108 millimetres. The print head uses a pigmented oil ink that can also be used to print in greyscale.

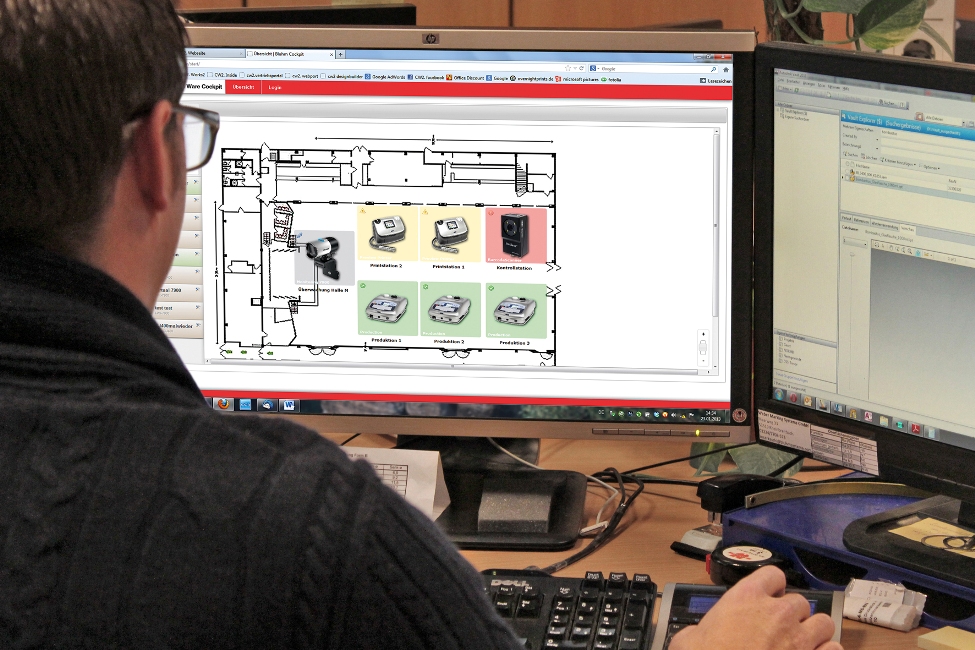

Comprehensive production monitoring

labelling systems, sensors or other production machines - with the Bluhmware cockpit software all devices that can be controlled via Ethernet and WLAN can be integrated and mapped in production environments (cockpits) using drag & drop. An overview of maintenance statuses, ink levels and productivity of the systems, centralised text changes, messaging service or webcam activation are just some of the software's functions.

Bluhm Systeme GmbH at the BrauBeviale 2019: Hall 4, Stand 315

Source: Bluhm Systeme GmbH