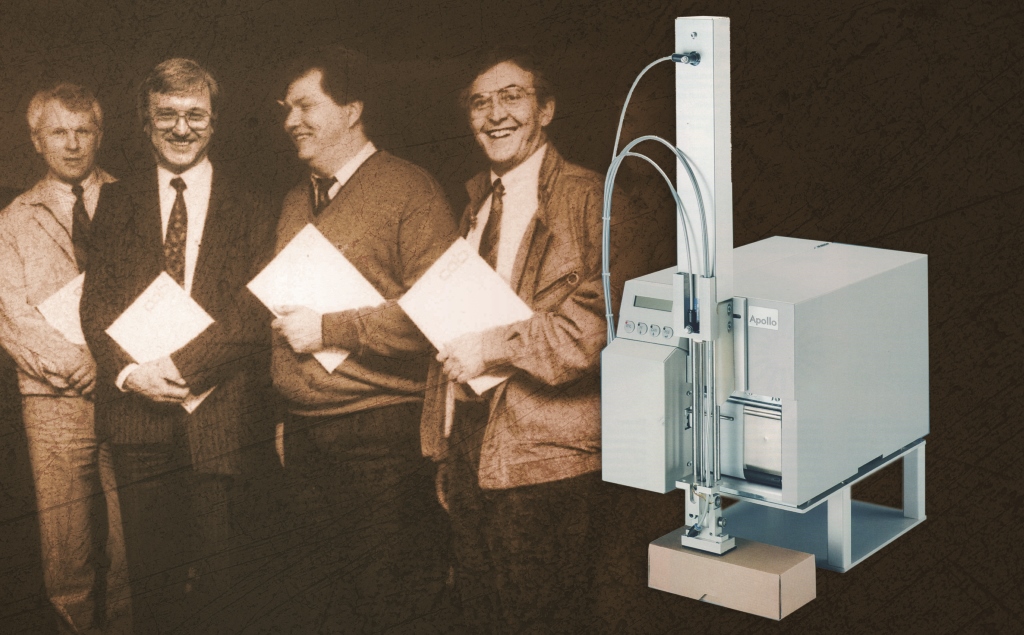

In the spring of 1975, precision engineering graduate Klaus Bardutzky teamed up with friends to develop components and production equipment for the electronics industry in a suburb of Karlsruhe in response to customer orders. He also designed dot matrix printers for labelling: the cab company was born.

It takes passion and perseverance to turn an idea into a global company. Klaus Bardutzky, born in 1942, has both. The precision engineering graduate teamed up with friends in spring 1975 to develop components and production equipment for the electronics industry in a suburb of Karlsruhe in response to customer orders. He also designed dot matrix printers for labelling: cab was born and trades under the name „Gesellschaft für Computer and Automationsbausteine mbH & Co. KG“.

42 years later, the Family business market leader in automated and high-precision labelling and Europe's leading labelling company. largest manufacturer of label printing systems. Since 1999, the headquarters have been located in the Karlsruhe Technology Park, a centre for high-tech companies. Every year, over 30,000 new devices leave the production facility in Sömmerda, Thuringia, to be shipped all over the world. Users of the label printers, labellers, label dispensers and marking lasers include global players such as Siemens, Bosch, Airbus, Continental and BMW as well as small and medium-sized companies. 350 employees in nine subsidiaries and 820 sales partners in more than 80 countries ensure the success of the company. nationwide distribution and a reliable service.

Hand in hand with the directive

In 1999, directly after graduating as an industrial engineer in Mannheim, he joined Alexander Bardutzky joined the company. He has shared the management with his father since 2009. Klaus Bardutzky is still a key figure in product development, while Alexander is responsible for sales, marketing, human resources and accounting. Relevant options are recognised at an early stage and assessed according to their market opportunities. The right tools are provided, market entries are planned and project plans are drawn up together with the specialist departments. According to the Bardutzkys, 60 per cent of their working time is dedicated to the new and further development of cab products and business processes.

cab: Multiple benchmarks set

In line with the technical innovation, the management level demonstrates mutual exchange to the workforce. Klaus and Alexander Bardutzky agree that this and flat hierarchies form the basis for employees to do their best for cab. The fact that it is sometimes worth taking untrodden paths is demonstrated by the Product history. cab has pioneered label printing in stand-alone mode. The company was also a pioneer in the hinged printer cover with a transparent viewing window through which the printing process can be observed. The comprehensive range of accessories for every conceivable application is still unique in this market segment today. Among other things, modules for automatic label transfer, devices for winding or unwinding the label material, cutting knives for separating or stackers for stacking the labels are offered.

[infotext icon]Chronology of cab product distribution1975 Own components and production equipment for the electronics industry

1989 External label printing systems

1995 Own label printing systems

1998 + own printing and labelling systems Hermes

1999 + own labelling laser FL

2012 + own label dispensers HS, VS

2014 + own labelling software cablabel

2017 + own IXOR high-performance labellers

cab has the right labels and thermal transfer ribbons for the perfect imprint[/infotext].

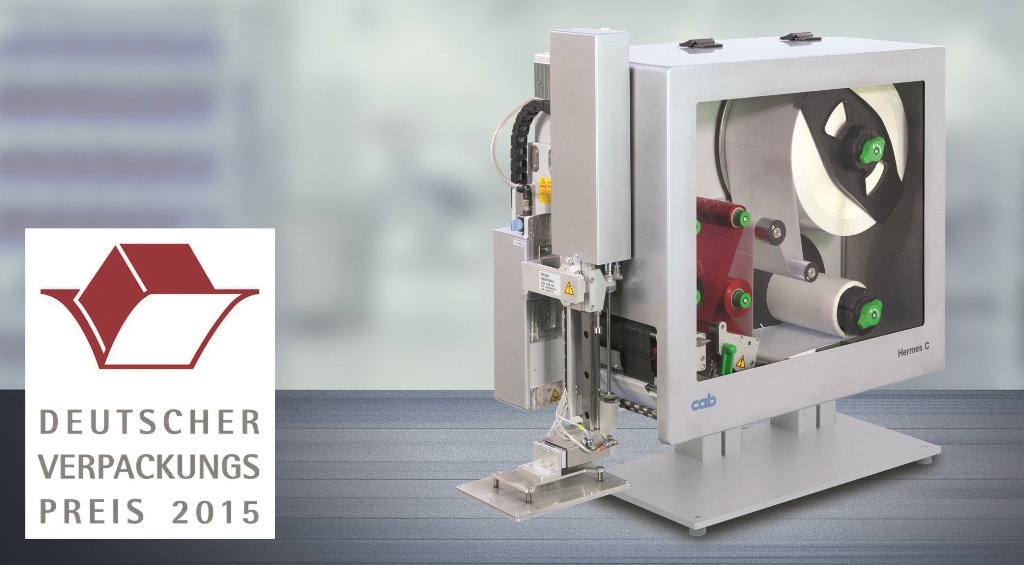

When the GHS, a globally standardised system for the classification and labelling of chemicals, was adopted and came into force under European law in 2010, cab printers of the XC series were the first to enable two-colour label printing in just one operation. This meant that customers no longer had to keep large quantities of pre-printed labels in stock. If labels are only partially printed, the thermal transfer ribbon is stopped during the label transport. This automatic saving system significantly reduces material consumption. With the Hermes C followed the first two-colour printing and labelling system of its kind, the Container labellinge.g. bottles, canisters, barrels, cartons or pallets. The integrated retraction system makes it possible to print and apply individual labels on demand without an empty label. This system was honoured with the German Packaging Award in 2015.

The future today

The manufacturing industry has been in a state of upheaval for years. Increasingly automated processes, networking and a steady stream of new regulations from legislators are driving demand for intelligent and optimised solutions for labelling on. In the automotive sector, labelling ensures the Traceability of components down to the smallest screw. In logistics, it guarantees the Scheduled delivery. Type plates on electrical appliances indicate performance data and use. In the pharmaceutical industry, labelling prevents health-related errors, while in the chemical industry it indicates risks when handling products - in multiple colours and without language barriers. Labelling on foodstuffs provides information about the ingredients and on textiles about the best way to care for them.

The Gallus Group forecasts global label demand for 2018 at 57 billion square metres, with sales of 114 billion US dollars. This corresponds to annual growth of 4.9 per cent since 2014. Klaus and Alexander Bardutzky have analysed the demand for smart solutions for coding and marking and aligned the architecture of cab devices accordingly. Long before Industry 4.0, Smart Manufacturing and the Internet of Things became terms for the interlinking of production with modern information and communication technologies, cab printing systems were based on Device intelligencewhich Fast processing of print jobs and complex possibilities of data exchange designed.

Faster than the competition

In a real application environment at a leading industrial group, cab's successful industrial A4+ printer was up to four times faster than the fastest competitor model in the 2016 test, measured from the start of printing to the start of printing. The successor presented in autumn 2016 SQUIX is even faster and has already printed the first line on the label within one second. The decisive factor for this top time is the interplay of intelligent firmware architecture, cab's own programming language JScript, which writes lean code, and the high-performance CPU. In the current cab industrial printers, the current fastest processor on the market. At 800 MHz, the processor clock rate is three times higher than that of its predecessors. Interfaces and protocols make it possible to communicate in both directions with higher-level networks, the Production planning or external controls to interact.

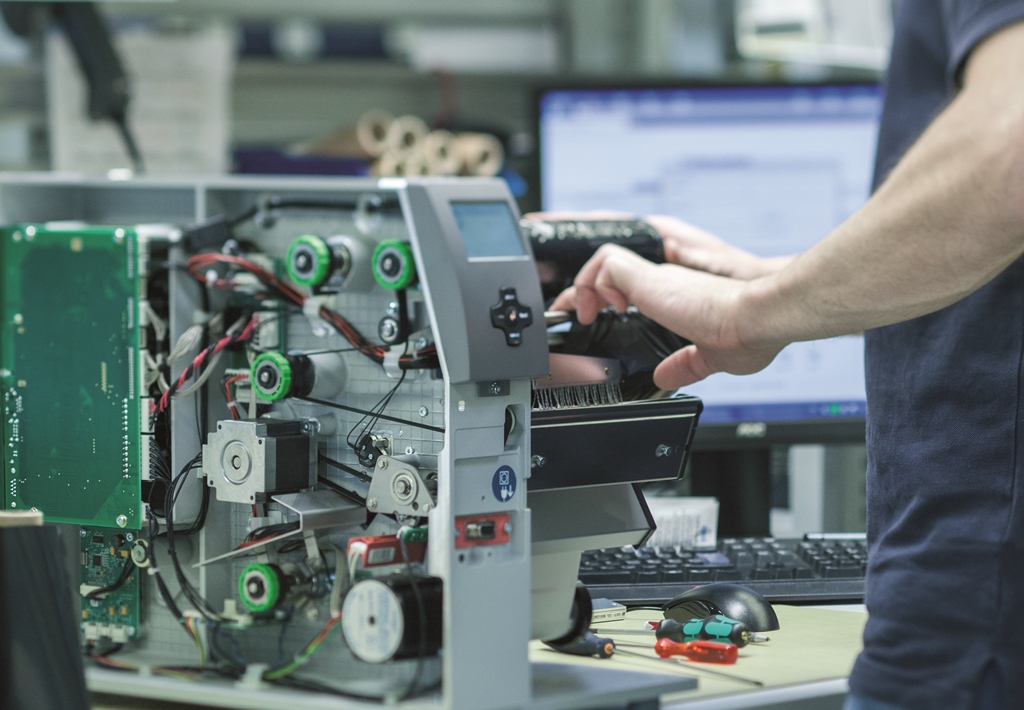

Made in Germany

The latest Made-in-Country Index from Statista and market researchers Dalia Research shows that goods manufactured in Germany remain „in“. There, the label "Made in Germany" First place out of 52 countries analysed. For the Bardutzkys, the choice of location for the production of parts and components, devices and systems was and is not a question of individual or temporary trends. If you ask them about the reasons for their loyalty to Germany as a business location, they immediately point to the high quality standards in the company. In their role model function, father and son emphasise in particular their responsibility towards the employees who have made cab more successful over the years.

The competences for the Complete process chain of electronics, mechanics and software are available in-house. All mechanical and plastic components for the appliances and systems have been manufactured in Sömmerda for 25 years. The ultra-modern production facilities are now spread across three large halls for production and storage, 10,000 m2 space and 160 employees. The company started with six employees in 1992. The machines and equipment at the site are continuously being developed. This creates the prerequisites for being able to economically produce even complex labelling systems with a high level of vertical integration. In addition to this local branches in Germany, France, the USA, Mexico, China, Taiwan and South Africa as well as the global network of sales partners worldwide for high availability of equipment, spare parts and manpower.

[infotext icon]In terms of business management, the Company mission statement to Independence out. Investments in employees, buildings, equipment and machinery are made from the company's own resources, Winnings into the company reinvested. The plans for a new building in the Karlsruhe Technology Park are already well advanced[/infotext].Listening to customers

At the Referral marketing Alexander Bardutzky relies on customers who are enthusiastic about the product and the services. In the first step, the applications and requirements are analysed together with the specialist consultants and cab then makes a realistic proposal for a solution. In the second step, user reports are created with selected customers. The motto here is: honest customer statements instead of self-praise, recommendations for action instead of advertising platitudes. Data-supported customer management makes it possible to expand existing customer relationships with additional offers, also from other product groups.

Essentially, customers demand the following when using the devices Long service life and 1001TP3 availability. Labelling must be precise and reliable. Especially with changing personnel, the Intuitive operability a criterion. The employees at cab continuously develop ideas on this basis and transfer new technologies to real applications. Newly developed devices are tested on site at selected key accounts. The knowledge gained flows into the next development steps until the product is ready for the market. The very special proximity to customers is also reflected in the figures: more than 88 per cent of users consistently rely on cab solutions - in some cases for over 20 years.